Semiconductor Manufacturing: Processes and Challenges

Semiconductor manufacturing is a complex and intricate process that involves the production of electronic devices such as integrated circuits (ICs) and microchips. These devices are the backbone of modern technology, powering everything from smartphones and computers to cars and medical devices. The semiconductor industry is constantly evolving and innovating to meet the growing demands of consumers for faster, smaller, and more powerful devices.

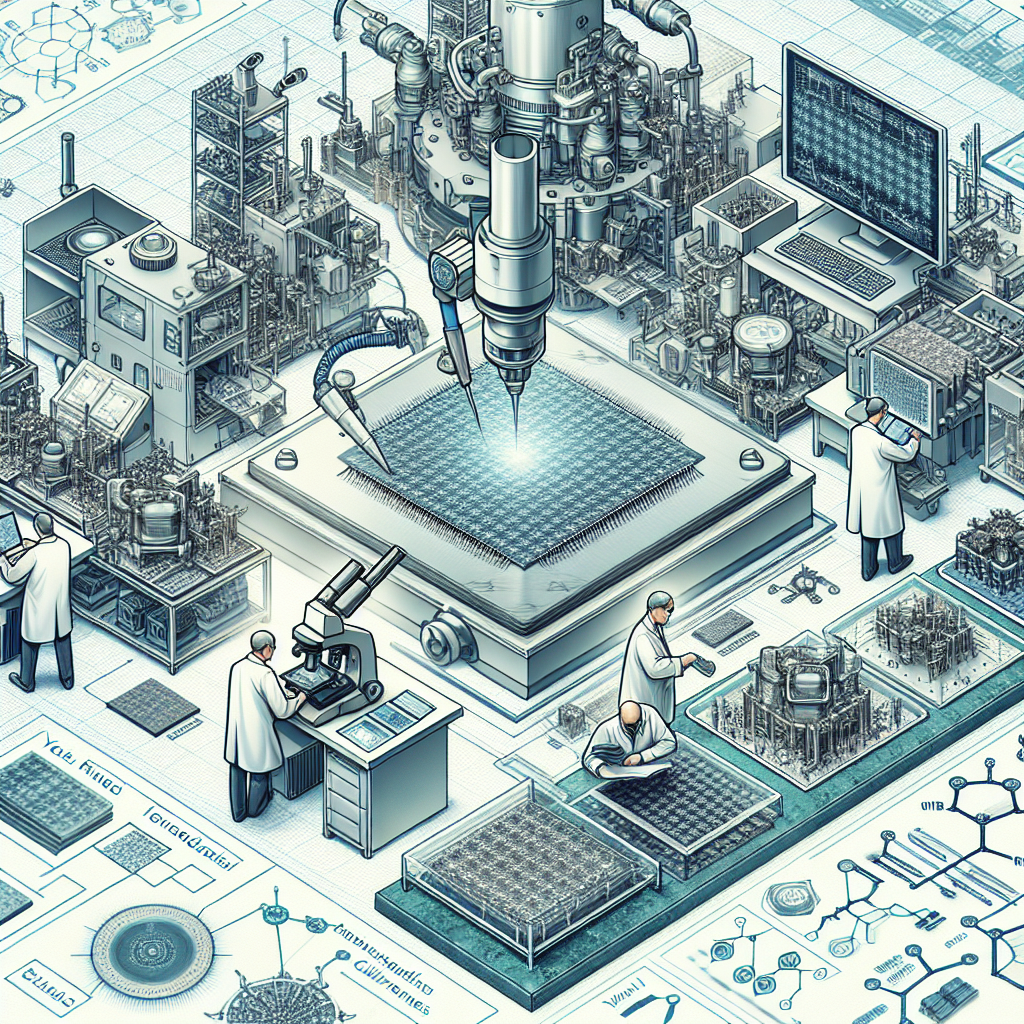

The semiconductor manufacturing process begins with the design of the IC or microchip. This design is then translated into a series of photomasks, which are used to etch patterns onto a silicon wafer. These patterns define the various components and circuitry of the device. The silicon wafer is then coated with a layer of photoresist, which is a light-sensitive material that allows for the transfer of the patterns from the photomasks to the wafer.

Next, the wafer goes through a series of lithography and etching processes to create the desired features on the surface. This involves the use of chemicals and high-energy beams to remove or deposit material on the wafer. This step is crucial in determining the performance and functionality of the final device.

After the patterning process is complete, the wafer undergoes a series of deposition steps to add layers of metal or insulating material to create the necessary connections and insulate the components. This is followed by a series of annealing and curing processes to ensure the stability and reliability of the device.

One of the biggest challenges in semiconductor manufacturing is the constant need to improve and innovate. As technology advances, the demand for smaller, faster, and more powerful devices continues to grow. This requires semiconductor manufacturers to develop new materials, processes, and equipment to keep up with these demands.

Another challenge is the increasing complexity of semiconductor devices. As devices become more integrated and multifunctional, the manufacturing process becomes more intricate and challenging. This requires a high level of precision and control to ensure the quality and reliability of the final product.

Additionally, the semiconductor industry faces challenges related to environmental sustainability and resource efficiency. The manufacturing process requires significant amounts of water, chemicals, and energy, which can have a negative impact on the environment. Semiconductor manufacturers are constantly striving to develop more sustainable and eco-friendly manufacturing processes to reduce their environmental footprint.

In conclusion, semiconductor manufacturing is a critical and complex process that plays a vital role in the advancement of technology. The industry faces numerous challenges, from the need for constant innovation and improvement to environmental sustainability. However, with continued research and development, semiconductor manufacturers are able to overcome these challenges and continue to push the boundaries of technology.