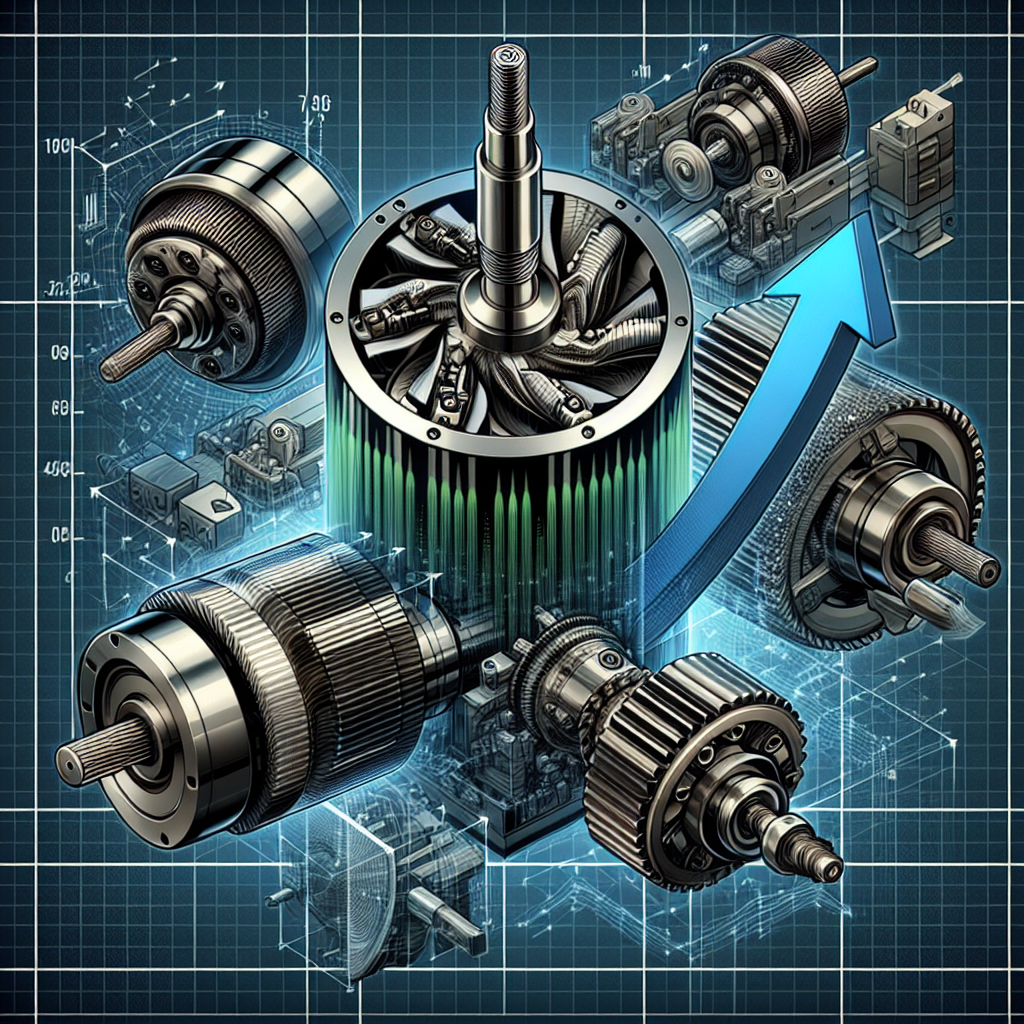

Optimizing Performance with Variable-speed Spindle Motors

Variable-speed spindle motors are a critical component in many industrial applications, including milling, drilling, and grinding. These motors allow for precise control over the speed at which a machine operates, which can have a significant impact on performance and efficiency.

One of the key benefits of variable-speed spindle motors is their ability to optimize performance based on the specific requirements of a given task. By adjusting the speed of the motor, operators can tailor the cutting or grinding process to the material being worked on, resulting in more precise and efficient outcomes. This level of control is especially important in industries where precision is crucial, such as aerospace and medical device manufacturing.

In addition to improving precision, variable-speed spindle motors can also enhance overall productivity. By operating at the optimal speed for a given task, these motors can reduce processing times and increase throughput. This can result in cost savings for manufacturers, as well as improved quality and consistency in the final product.

Another advantage of variable-speed spindle motors is their energy efficiency. By running at lower speeds when possible, these motors can consume less power and reduce operating costs. This can be particularly beneficial for manufacturers looking to improve their sustainability practices and reduce their carbon footprint.

To fully harness the benefits of variable-speed spindle motors, it is important for operators to understand how to properly program and control these motors. This may involve setting up specific parameters for different types of materials or processes, as well as regularly monitoring and adjusting the motor’s speed as needed. Training and expertise in this area can help ensure that the motor is being used to its full potential and maximizing performance.

In conclusion, variable-speed spindle motors offer a range of benefits for industrial applications, including improved precision, productivity, and energy efficiency. By optimizing performance with these motors, manufacturers can enhance their operations and stay competitive in today’s fast-paced market. Investing in the right equipment and expertise can help businesses make the most of this technology and achieve their performance goals.