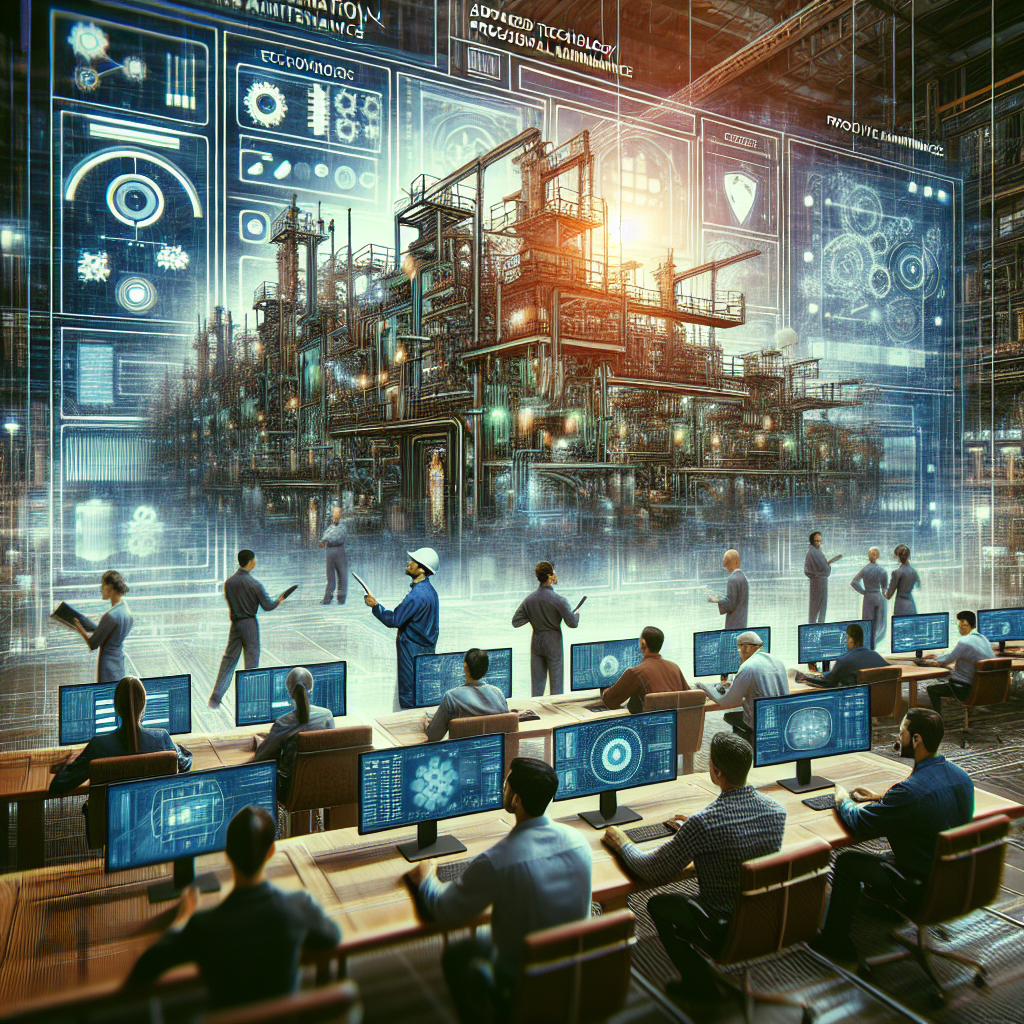

The Role of Technology in Proactive Maintenance

Proactive maintenance is a key strategy used by companies to prevent equipment breakdowns and minimize downtime. This approach involves regularly monitoring equipment, identifying potential issues before they escalate into major problems, and taking preventive action to address them.

Technology plays a crucial role in proactive maintenance, enabling companies to streamline their maintenance processes, improve equipment monitoring, and enhance overall efficiency. Here are some ways in which technology is transforming proactive maintenance:

1. Predictive maintenance tools: Predictive maintenance tools use data analytics and machine learning algorithms to predict when equipment is likely to fail. By analyzing historical data and real-time sensor data, these tools can identify patterns and trends that indicate potential issues. This allows maintenance teams to address problems before they occur, reducing unplanned downtime and avoiding costly repairs.

2. Condition monitoring sensors: Condition monitoring sensors are used to monitor the health of equipment in real-time. These sensors can track variables such as temperature, vibration, and pressure, providing valuable insights into the performance of machinery. By detecting abnormalities early on, maintenance teams can take proactive measures to prevent equipment failures.

3. Asset management software: Asset management software helps companies track the maintenance history of their equipment, schedule preventive maintenance tasks, and optimize maintenance workflows. This software allows maintenance teams to keep track of equipment inventory, monitor maintenance schedules, and generate reports on equipment performance. By centralizing maintenance data, companies can make informed decisions about their maintenance strategies and improve overall equipment reliability.

4. Mobile maintenance apps: Mobile maintenance apps enable maintenance technicians to access equipment information, log maintenance activities, and receive real-time alerts on their mobile devices. These apps streamline communication between maintenance teams and provide instant access to critical maintenance data. By empowering technicians with mobile technology, companies can improve response times, enhance collaboration, and increase productivity.

5. Internet of Things (IoT) devices: IoT devices are interconnected sensors and devices that collect and transmit data over the internet. These devices can be integrated into equipment to monitor performance, track usage patterns, and detect anomalies. By leveraging IoT technology, companies can gather valuable insights into equipment health, optimize maintenance schedules, and improve overall equipment reliability.

In conclusion, technology plays a crucial role in proactive maintenance by enabling companies to monitor equipment, predict failures, and take preventive action. By leveraging predictive maintenance tools, condition monitoring sensors, asset management software, mobile maintenance apps, and IoT devices, companies can enhance their maintenance strategies, reduce downtime, and improve equipment reliability. Embracing technology in proactive maintenance is essential for companies looking to stay ahead of the curve and ensure the smooth operation of their equipment.