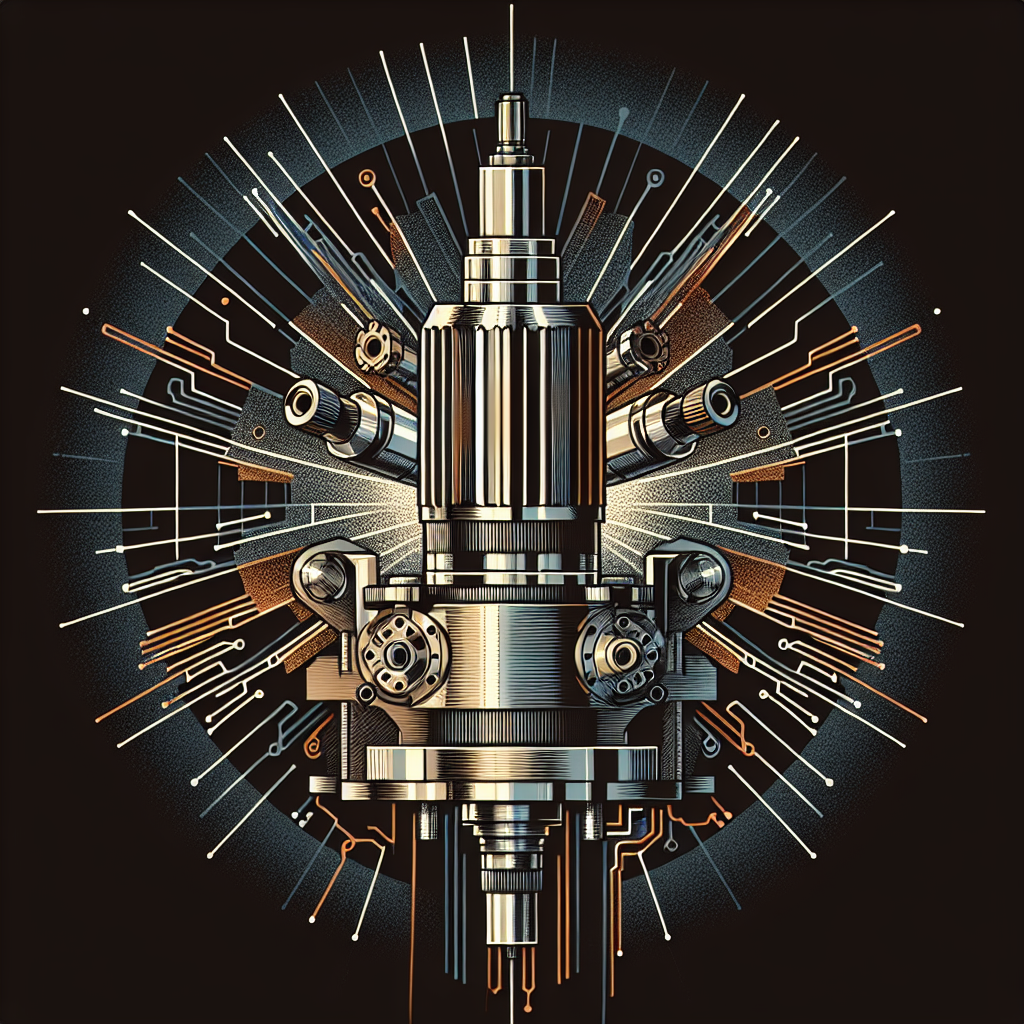

The Role of Spindle Motors in CNC Machining

CNC machining has revolutionized the manufacturing industry by allowing for precise and efficient production of complex parts. Central to the operation of CNC machines are spindle motors, which play a crucial role in driving the cutting tools that shape the workpiece.

Spindle motors are responsible for rotating the cutting tools at high speeds, allowing for precise and efficient material removal. These motors are typically electric motors that can range in size and power, depending on the specific requirements of the machining process. The speed and power of the spindle motor can be controlled by the CNC machine’s computerized system, allowing for precise control over the cutting process.

One of the key advantages of spindle motors in CNC machining is their ability to operate at high speeds with minimal vibration. This is essential for achieving high levels of precision and surface finish on the workpiece. Spindle motors are also designed to provide high torque, ensuring that the cutting tool can effectively remove material without slowing down or causing damage to the workpiece.

In addition to speed and power, spindle motors in CNC machining also play a role in the overall efficiency of the process. By providing reliable and consistent performance, these motors help to minimize downtime and maximize productivity. This is especially important in high-volume manufacturing environments where even small delays can have a significant impact on production schedules.

Furthermore, advancements in spindle motor technology have led to the development of more energy-efficient and environmentally friendly options. These motors are designed to consume less power while still delivering high performance, helping to reduce energy costs and minimize the carbon footprint of CNC machining operations.

Overall, spindle motors are a critical component of CNC machining, playing a key role in driving the cutting tools that shape the workpiece. By providing high-speed rotation, precise control, and efficient performance, these motors help to ensure the success of modern manufacturing processes. As technology continues to advance, we can expect to see further improvements in spindle motor design and performance, further enhancing the capabilities of CNC machining.