Maximizing Performance with High-Speed Spindle Motors

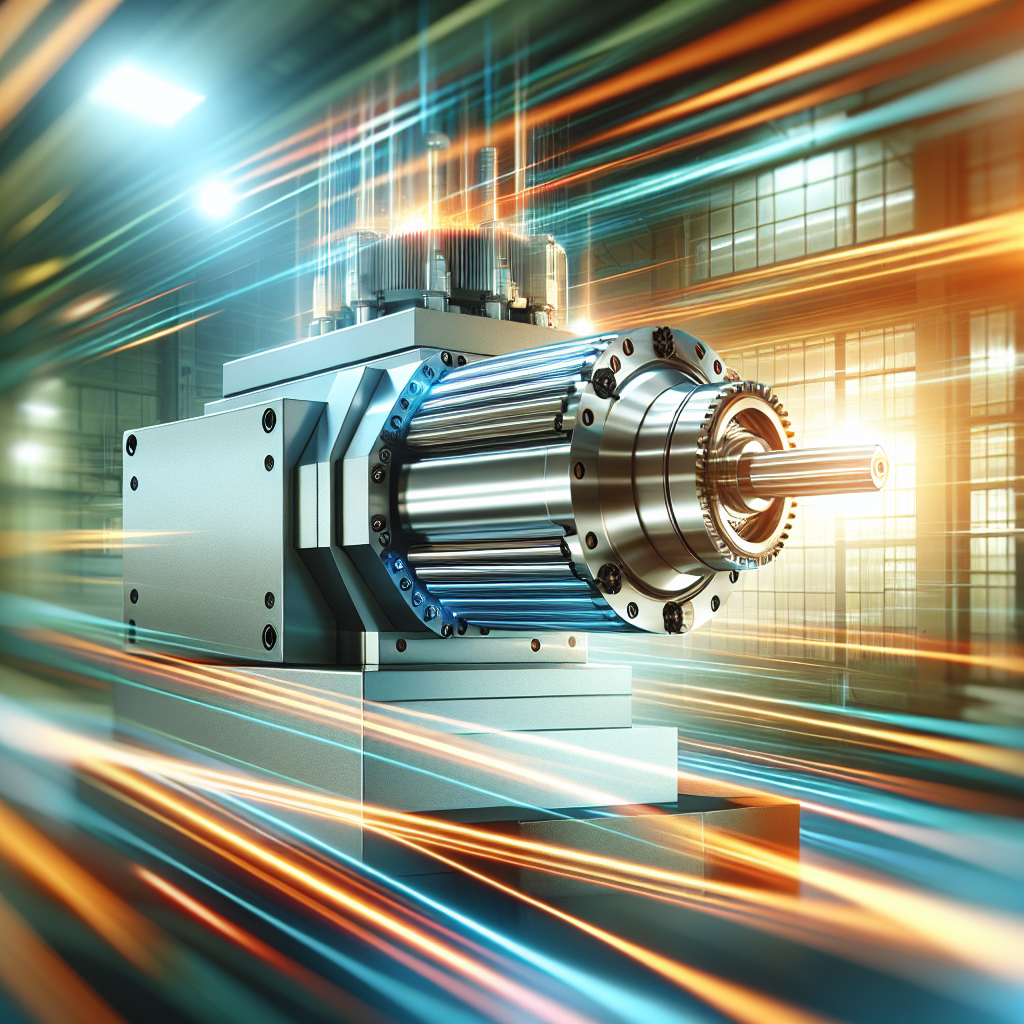

High-speed spindle motors are a crucial component in many industrial applications, such as milling, drilling, and grinding. These motors are designed to operate at extremely high speeds, allowing for faster and more precise machining operations. By maximizing the performance of high-speed spindle motors, manufacturers can increase productivity, reduce machining times, and improve overall product quality.

One of the key factors in maximizing the performance of high-speed spindle motors is ensuring proper maintenance and upkeep. Regular cleaning, lubrication, and inspection of the motor components can help prevent wear and tear, prolonging the lifespan of the motor and ensuring consistent performance. It is also important to monitor the motor’s temperature and vibration levels, as excessive heat or vibration can indicate potential issues that may affect performance.

Additionally, selecting the right tooling and cutting parameters is essential for optimizing the performance of high-speed spindle motors. Using the correct tooling material, geometry, and coatings can help reduce tool wear and improve cutting efficiency. It is also important to adjust cutting speeds, feeds, and depths of cut to match the capabilities of the spindle motor, ensuring optimal performance and extending tool life.

Another important aspect of maximizing performance with high-speed spindle motors is proper programming and toolpath optimization. Utilizing advanced CAM software and toolpath strategies can help minimize tool deflection, reduce cutting forces, and improve surface finish quality. By optimizing toolpaths and programming parameters, manufacturers can achieve faster machining speeds, higher material removal rates, and improved overall efficiency.

Furthermore, investing in high-quality spindle motors with advanced features, such as high torque output, precision bearings, and integrated cooling systems, can also help maximize performance. These advanced features can enhance the motor’s capabilities, allowing for higher speeds, greater accuracy, and increased reliability. Additionally, regular calibration and tuning of the spindle motor can help ensure optimal performance and consistency in machining operations.

In conclusion, maximizing performance with high-speed spindle motors is essential for achieving efficient and accurate machining operations. By implementing proper maintenance practices, selecting the right tooling and cutting parameters, optimizing toolpaths, and investing in high-quality spindle motors, manufacturers can enhance productivity, reduce machining times, and improve overall product quality. By maximizing the performance of high-speed spindle motors, manufacturers can stay competitive in today’s fast-paced manufacturing environment.