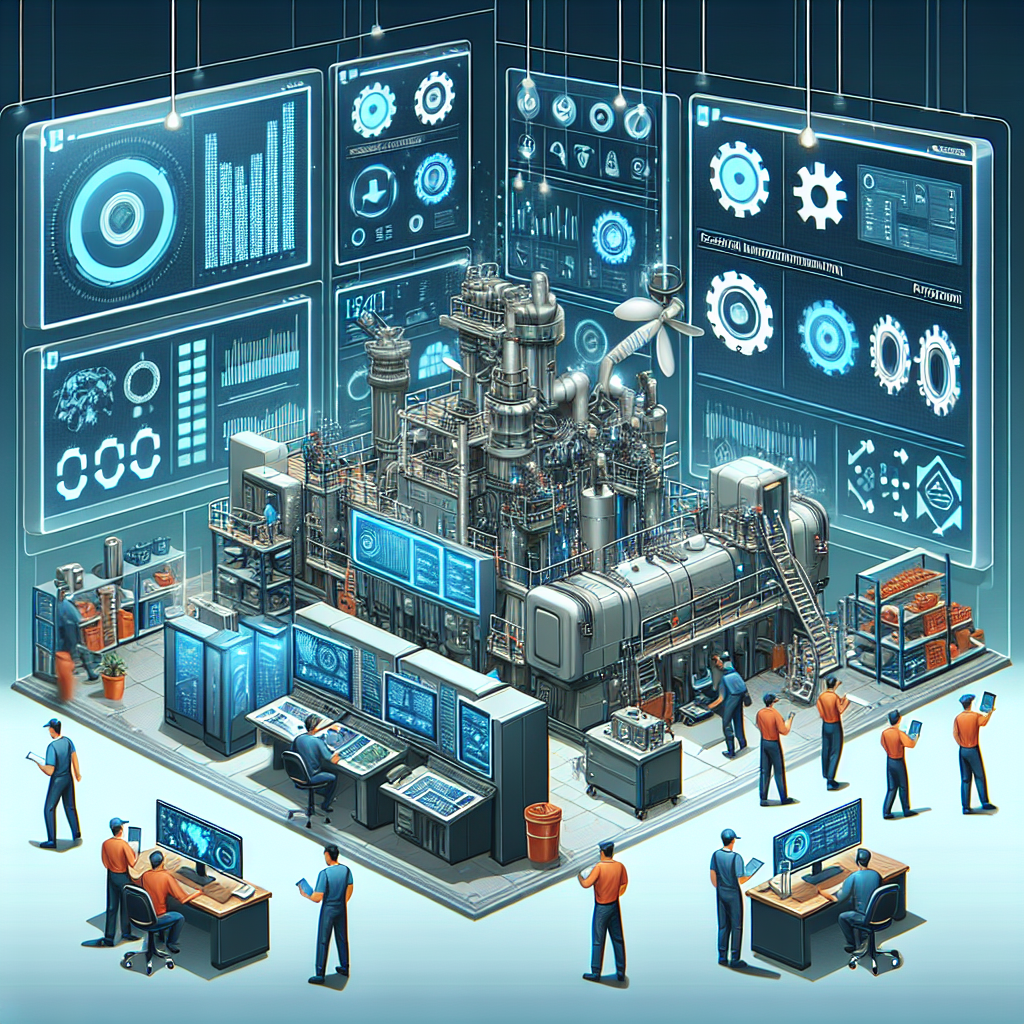

In today’s fast-paced industrial landscape, proactive maintenance programs have become essential for companies looking to maximize the lifespan of their equipment and reduce costly downtime. By implementing proactive maintenance strategies, companies can identify and address potential issues before they escalate into major problems, ultimately saving time and money in the long run.

Case studies of successful proactive maintenance programs serve as valuable examples for companies looking to improve their maintenance practices. These case studies highlight the benefits of proactive maintenance, including increased equipment reliability, improved productivity, and reduced maintenance costs.

One such case study involves a manufacturing company that implemented a proactive maintenance program for its production equipment. By conducting regular inspections, monitoring equipment performance, and scheduling preventive maintenance tasks, the company was able to significantly reduce unexpected breakdowns and downtime. As a result, the company saw an increase in production output and a decrease in maintenance costs, ultimately leading to improved profitability.

Another example of successful proactive maintenance implementation comes from a transportation company that utilized predictive maintenance techniques to monitor the condition of its fleet vehicles. By analyzing data from sensors and monitoring equipment performance in real-time, the company was able to detect potential issues before they caused any disruptions to their operations. This proactive approach not only saved the company money on costly repairs but also improved the safety and reliability of their vehicles, ultimately leading to increased customer satisfaction.

Overall, these case studies demonstrate the importance of proactive maintenance programs in today’s industrial environment. By investing in proactive maintenance strategies, companies can improve equipment reliability, reduce downtime, and ultimately increase their bottom line. As technology continues to advance, companies that embrace proactive maintenance will be better equipped to stay ahead of the curve and outperform their competitors.

Leave a Reply

You must be logged in to post a comment.