Your cart is currently empty!

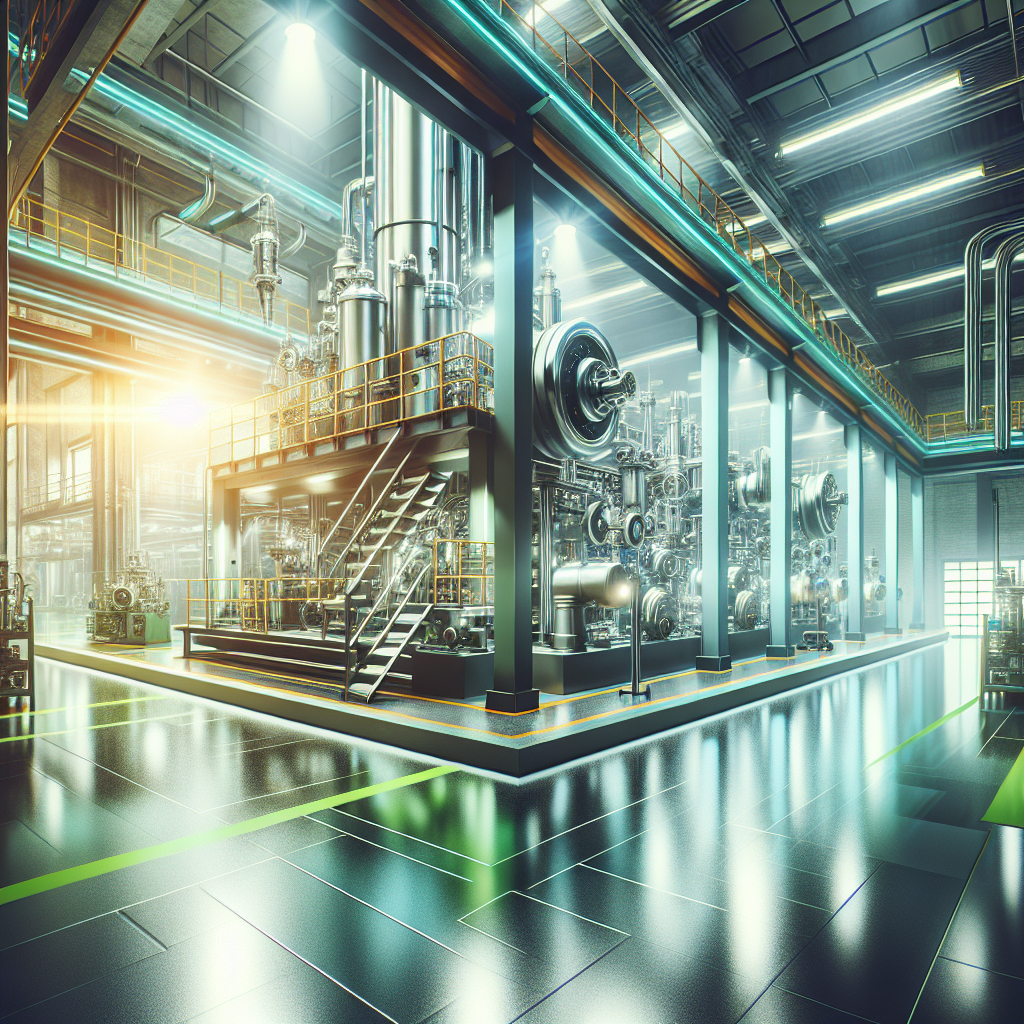

Case Study: The Success of Proactive Maintenance in Industry

In today’s fast-paced industrial environment, the importance of proactive maintenance cannot be overstated. By implementing a proactive maintenance strategy, companies can prevent costly breakdowns, minimize downtime, and ensure that their equipment is operating at peak efficiency. One industry that has seen significant success with proactive maintenance is the manufacturing sector.

A case study conducted on a manufacturing plant that implemented proactive maintenance found that the plant was able to reduce maintenance costs by 25% and increase equipment uptime by 20%. These impressive results can be attributed to the plant’s shift from a reactive maintenance approach to a proactive one.

Under the reactive maintenance model, equipment failures were addressed only after they occurred, leading to costly repairs and unplanned downtime. In contrast, proactive maintenance involves regularly scheduled inspections, preventive maintenance tasks, and predictive maintenance techniques to identify and address potential issues before they escalate into major problems.

By implementing a proactive maintenance program, the manufacturing plant was able to identify and address issues such as worn-out parts, lubrication deficiencies, and equipment malfunctions before they caused costly breakdowns. This proactive approach not only reduced maintenance costs but also increased equipment reliability and extended the lifespan of the plant’s machinery.

In addition to cost savings and increased uptime, proactive maintenance also allows companies to better plan and schedule maintenance activities, leading to improved overall operational efficiency. By conducting regular inspections and maintenance tasks, companies can optimize their equipment performance, minimize the risk of unexpected breakdowns, and ensure that their production processes run smoothly.

Overall, the success of proactive maintenance in the manufacturing industry demonstrates the significant benefits of adopting a proactive approach to maintenance. By investing in regular inspections, preventive maintenance tasks, and predictive maintenance techniques, companies can reduce costs, increase uptime, and improve overall operational efficiency. As technology continues to advance, proactive maintenance will become increasingly important for companies looking to stay competitive in today’s rapidly changing industrial landscape.

Leave a Reply