Your cart is currently empty!

Choosing the Right Actuator for Your Application: A Comprehensive Guide

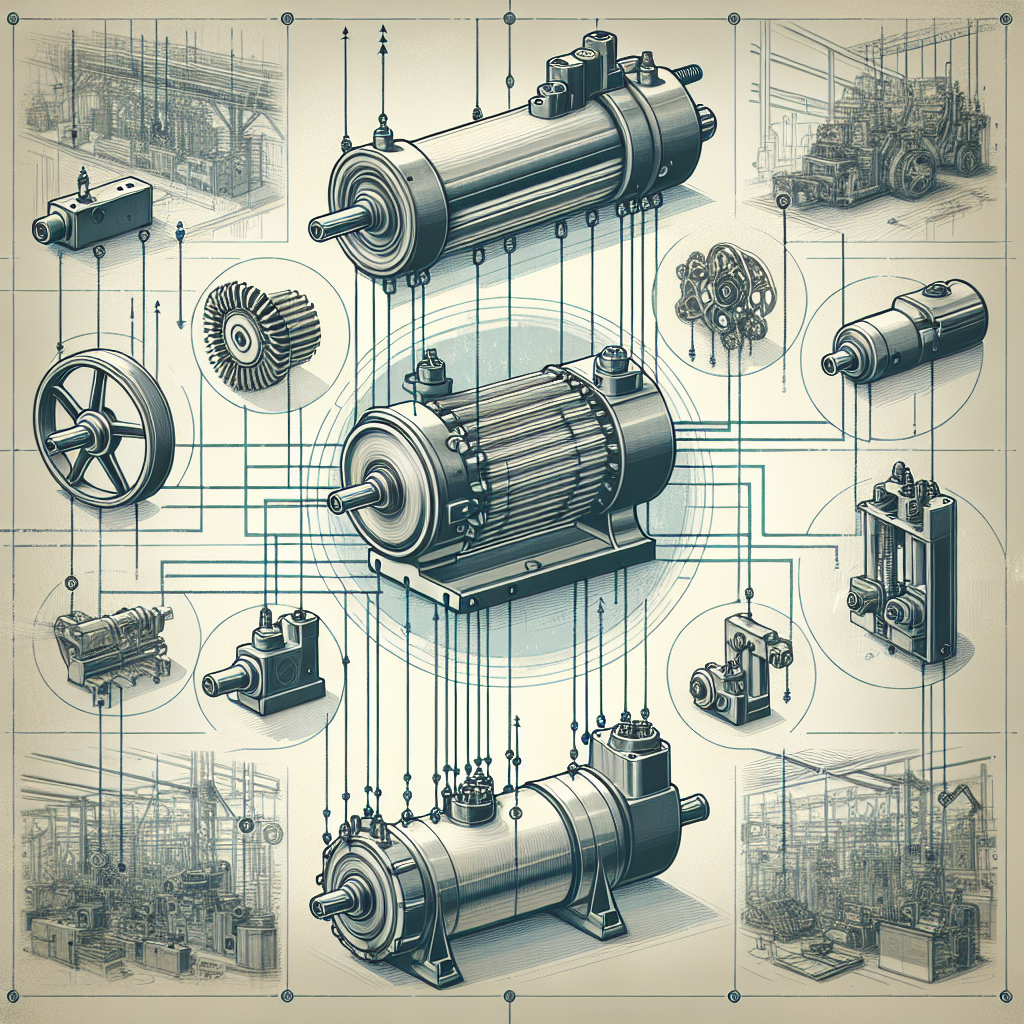

Actuators are essential components in various mechanical systems, as they are responsible for converting energy into motion. Choosing the right actuator for your application is crucial in ensuring optimal performance and efficiency. With a wide range of actuators available on the market, it can be overwhelming to select the best one for your specific needs. In this comprehensive guide, we will discuss the key factors to consider when choosing an actuator for your application.

1. Type of Actuator:

There are several types of actuators available, including hydraulic, pneumatic, electric, and electromechanical actuators. Each type has its own advantages and disadvantages, so it is important to consider the specific requirements of your application before selecting the right type of actuator. Hydraulic actuators are ideal for applications requiring high force and precision, while pneumatic actuators are suitable for fast and simple motion control. Electric actuators are preferred for their precision and accuracy, while electromechanical actuators offer a combination of speed and precision.

2. Load and Force Requirements:

It is important to determine the load and force requirements of your application before selecting an actuator. Consider factors such as the weight of the load, the distance it needs to be moved, and the speed at which it needs to be moved. This will help you determine the size and type of actuator that is best suited for your application.

3. Speed and Accuracy:

The speed and accuracy of the actuator are crucial factors to consider when choosing the right one for your application. If your application requires precise positioning and control, you will need an actuator that offers high accuracy and repeatability. Similarly, if your application requires fast and efficient motion control, you will need an actuator that offers high speed and responsiveness.

4. Environmental Conditions:

Consider the environmental conditions in which the actuator will be operating when choosing the right one for your application. Factors such as temperature, humidity, and exposure to chemicals or corrosive substances can impact the performance and lifespan of the actuator. Make sure to select an actuator that is designed to withstand the specific environmental conditions of your application.

5. Cost and Maintenance:

Lastly, consider the cost and maintenance requirements of the actuator when making your selection. While it may be tempting to opt for a cheaper actuator, keep in mind that lower-cost options may require more frequent maintenance and replacement, leading to increased long-term costs. Consider the overall lifecycle cost of the actuator, including maintenance, repair, and replacement costs, before making your decision.

In conclusion, choosing the right actuator for your application is essential in ensuring optimal performance and efficiency. Consider factors such as the type of actuator, load and force requirements, speed and accuracy, environmental conditions, and cost and maintenance when making your selection. By carefully evaluating these factors, you can choose the best actuator for your specific needs and achieve optimal results in your application.

Leave a Reply