Common Applications of Actuators in Robotics and Manufacturing

Actuators are essential components in both robotics and manufacturing industries. These devices are responsible for converting energy into mechanical motion, allowing machines to perform various tasks. Actuators play a crucial role in controlling the movement of robotic arms, conveyor belts, and other automated systems. In this article, we will discuss some common applications of actuators in robotics and manufacturing.

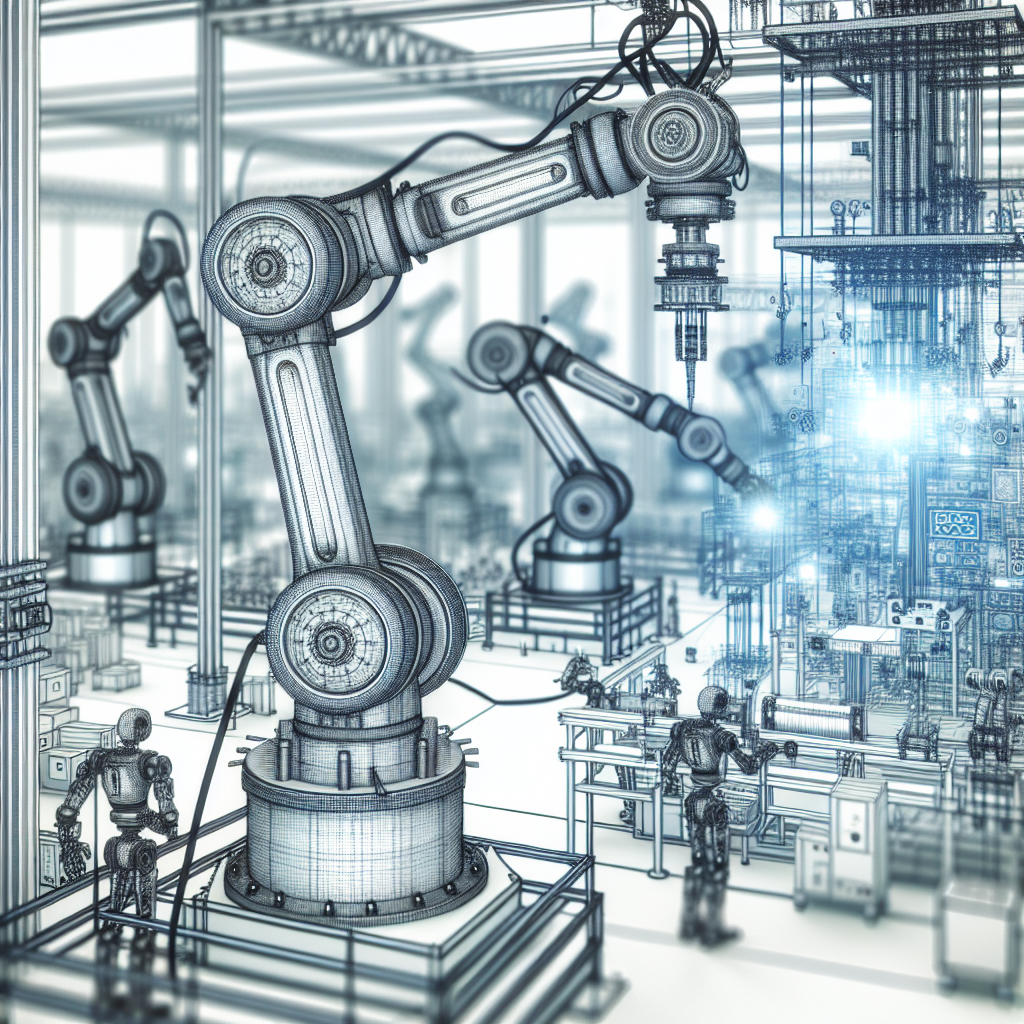

One of the most common applications of actuators in robotics is in the control of robotic arms. These arms are used in a wide range of industries, including automotive, electronics, and healthcare. Actuators are responsible for controlling the movement of the robotic arm, allowing it to pick up and manipulate objects with precision. By using actuators, robotic arms can perform tasks that require dexterity and accuracy, such as assembling components or performing delicate surgical procedures.

Another common application of actuators in robotics is in the control of grippers and end effectors. Grippers are used to grasp and hold objects, while end effectors are used to perform specific tasks, such as welding or drilling. Actuators are used to control the opening and closing of grippers and the movement of end effectors, allowing robots to carry out complex tasks with ease.

In the manufacturing industry, actuators are used in a wide range of applications, including controlling conveyor belts, valves, and robotic welding arms. Conveyor belts are used to transport materials and products throughout a manufacturing facility. Actuators are used to control the speed and direction of the conveyor belt, allowing for efficient and precise movement of materials.

Valves are used to control the flow of liquids and gases in manufacturing processes. Actuators are used to open and close valves, regulating the flow of materials and ensuring that production runs smoothly. Actuators are also used in robotic welding arms, which are used to weld metal components together. By using actuators, manufacturers can automate the welding process, increasing efficiency and accuracy.

Overall, actuators are essential components in both robotics and manufacturing industries. These devices play a crucial role in controlling the movement of robotic arms, grippers, conveyor belts, and other automated systems. By using actuators, manufacturers can increase efficiency, accuracy, and productivity in their operations. As technology continues to advance, the applications of actuators in robotics and manufacturing will only continue to grow.