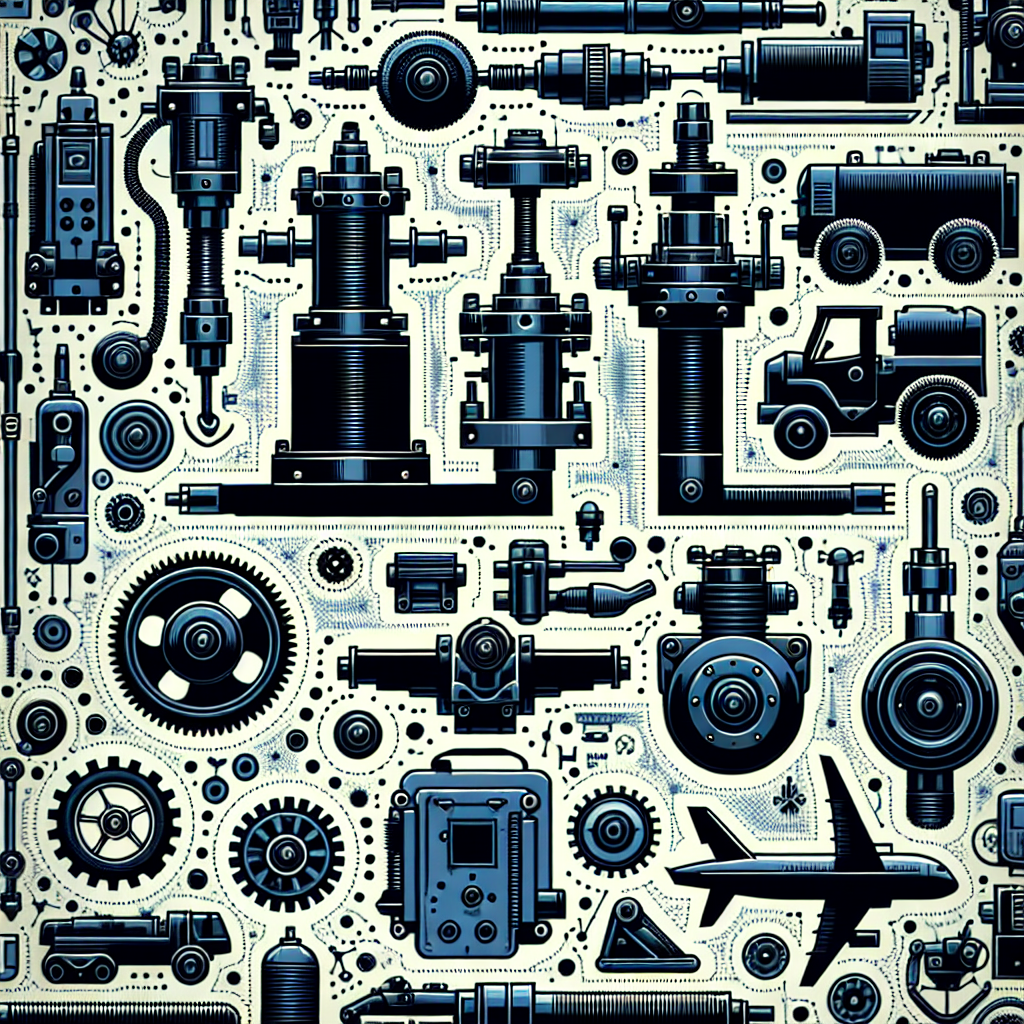

Actuators are devices that convert energy into motion, and they play a vital role in various industries and applications. There are several types of actuators, each with its own unique features and uses. In this article, we will explore the different types of actuators and their applications.

1. Electric Actuators:

Electric actuators are powered by electricity and are commonly used in industrial automation, robotics, and automotive applications. They are known for their precision, speed, and accuracy. Electric actuators can be further categorized into different types such as linear actuators, rotary actuators, and solenoids. Linear actuators are used for linear motion, while rotary actuators are used for rotational motion. Solenoids are used for controlling valves and switches.

2. Hydraulic Actuators:

Hydraulic actuators use hydraulic fluid to generate motion. They are commonly used in heavy-duty applications where high force and precision are required. Hydraulic actuators are known for their high force density, reliability, and durability. They are often used in construction equipment, aerospace, and marine applications.

3. Pneumatic Actuators:

Pneumatic actuators use compressed air to generate motion. They are lightweight, cost-effective, and easy to install. Pneumatic actuators are commonly used in manufacturing, automotive, and packaging industries. They are known for their high speed and efficiency. Pneumatic actuators can be further categorized into different types such as linear actuators, rotary actuators, and grippers.

4. Mechanical Actuators:

Mechanical actuators use mechanical force to generate motion. They are simple, reliable, and cost-effective. Mechanical actuators are commonly used in manual applications where precision and speed are not critical. Mechanical actuators are often used in hand tools, valves, and switches.

5. Piezoelectric Actuators:

Piezoelectric actuators use piezoelectric materials to generate motion. They are known for their high precision, fast response time, and low power consumption. Piezoelectric actuators are commonly used in nanotechnology, microscopy, and medical devices. They are used for precise positioning and fine motion control.

In conclusion, actuators play a crucial role in various industries and applications. Each type of actuator has its own unique features and uses. Electric actuators are known for their precision and speed, hydraulic actuators for their high force density, pneumatic actuators for their high speed and efficiency, mechanical actuators for their simplicity and reliability, and piezoelectric actuators for their high precision and fast response time. Understanding the different types of actuators and their applications can help in choosing the right actuator for a specific application.

Leave a Reply