Your cart is currently empty!

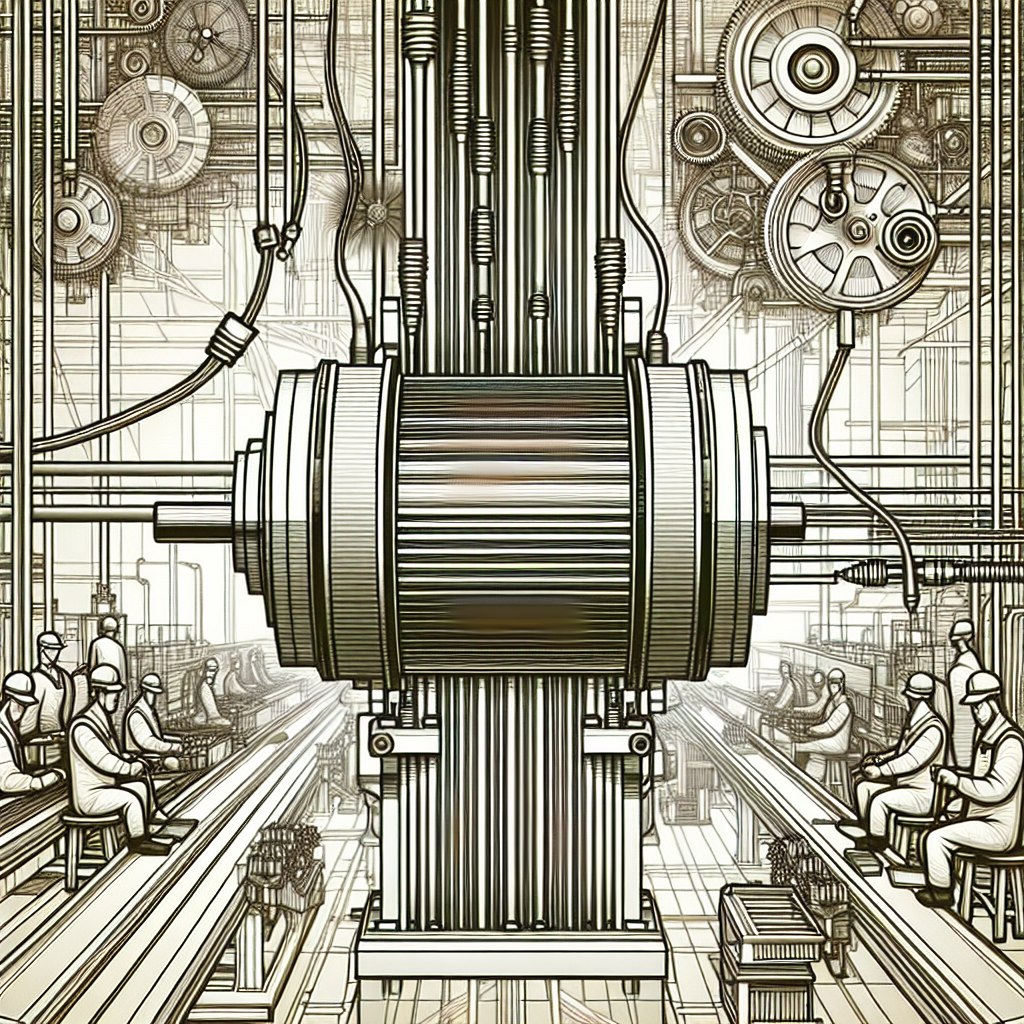

How Spindle Motors Improve Efficiency and Precision in Manufacturing

Spindle motors are a crucial component in the manufacturing industry, playing a key role in improving efficiency and precision in various manufacturing processes. These motors are responsible for driving the rotation of cutting tools, grinding wheels, and other tools used in machining operations.

One of the primary benefits of spindle motors is their ability to provide high-speed rotation, allowing for faster machining processes. This increased speed results in higher productivity and reduced cycle times, ultimately leading to cost savings for manufacturers. Additionally, the high rotational speed of spindle motors enables them to achieve greater precision in machining operations, resulting in higher quality finished products.

Spindle motors also offer superior control and stability during operation, ensuring consistent and accurate performance. This level of control is essential for achieving tight tolerances and intricate designs in manufacturing processes. The precise control provided by spindle motors also helps to minimize material waste and reduce the need for rework, further enhancing efficiency in manufacturing operations.

Another advantage of spindle motors is their compact size and minimal footprint, making them ideal for use in a variety of machining applications. Their compact design allows for greater flexibility in machine layout and configuration, enabling manufacturers to optimize their production processes and maximize floor space utilization.

Furthermore, advancements in spindle motor technology have led to the development of high-performance motors that are capable of delivering increased power and torque while maintaining energy efficiency. This increased power and torque allow for more aggressive cutting and machining operations, resulting in higher material removal rates and improved overall productivity.

Overall, spindle motors play a crucial role in improving efficiency and precision in manufacturing processes. Their high-speed rotation, precise control, compact design, and advanced technology make them essential components for achieving high-quality, cost-effective production in various industries. By investing in spindle motors, manufacturers can enhance their machining capabilities, increase productivity, and ultimately gain a competitive edge in today’s rapidly evolving manufacturing landscape.

Leave a Reply