Your cart is currently empty!

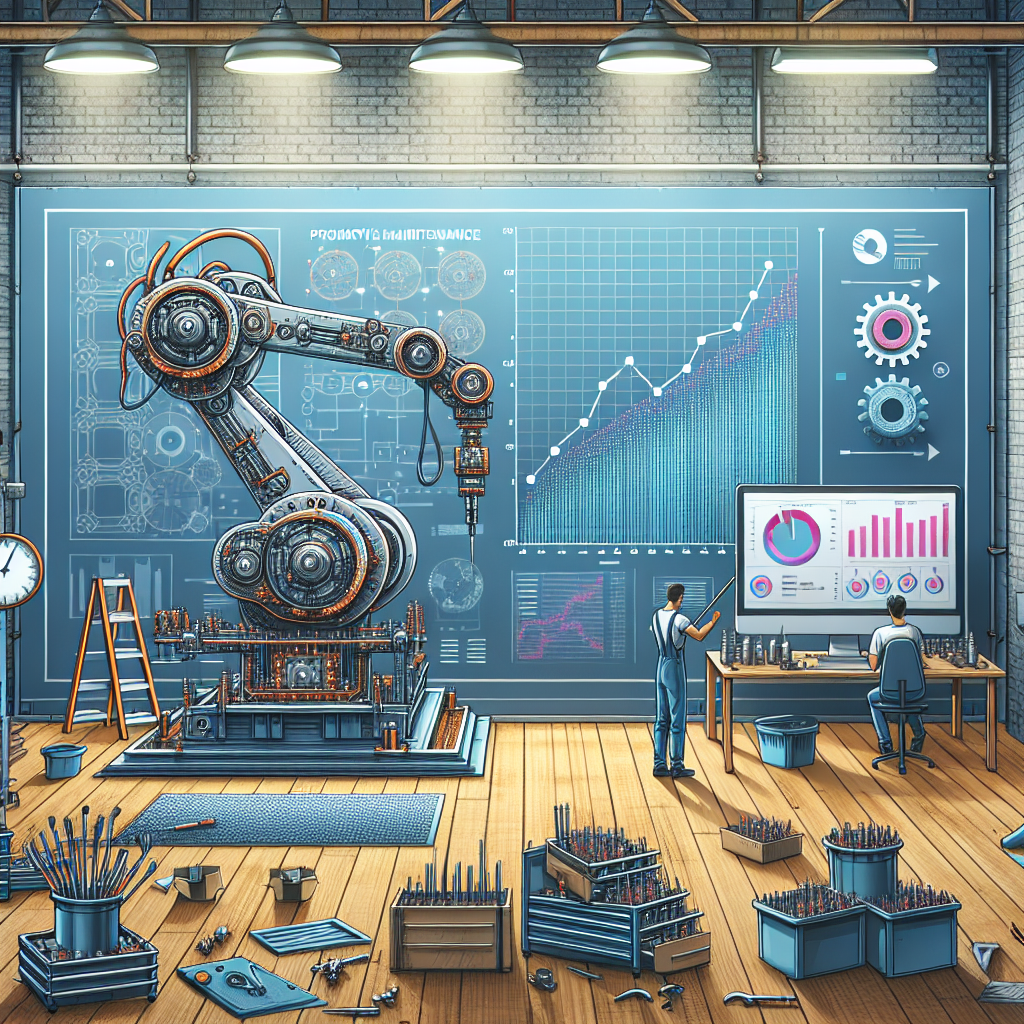

Maximizing Efficiency and Minimizing Downtime with Proactive Maintenance Strategies

In today’s fast-paced business environment, maximizing efficiency and minimizing downtime are essential for success. One way to achieve this is through proactive maintenance strategies. By implementing proactive maintenance measures, businesses can prevent equipment failures, increase productivity, and reduce unexpected downtime.

Proactive maintenance involves regularly monitoring and inspecting equipment to identify potential issues before they escalate into costly problems. This proactive approach allows businesses to address maintenance needs in a timely manner, minimizing the risk of equipment breakdowns and unplanned downtime.

One key proactive maintenance strategy is implementing a preventive maintenance schedule. This involves performing routine maintenance tasks, such as cleaning, lubricating, and inspecting equipment, on a scheduled basis. By adhering to a preventive maintenance schedule, businesses can ensure that their equipment is in optimal condition and reduce the likelihood of unexpected breakdowns.

Another proactive maintenance strategy is predictive maintenance, which involves using technology to monitor equipment performance and predict when maintenance is needed. By analyzing data collected from sensors and monitoring systems, businesses can identify trends and patterns that indicate potential issues with equipment. This allows them to address maintenance needs before they result in downtime.

Additionally, implementing a proactive spare parts management system can help businesses minimize downtime by ensuring that they have the necessary parts on hand to quickly address equipment failures. By maintaining an inventory of critical spare parts and having a system in place to quickly order replacement parts when needed, businesses can reduce the time it takes to repair equipment and get it back up and running.

Overall, proactive maintenance strategies are essential for maximizing efficiency and minimizing downtime in today’s competitive business environment. By taking a proactive approach to maintenance, businesses can prevent equipment failures, increase productivity, and reduce the risk of unexpected downtime. Investing in proactive maintenance measures is a smart business decision that can ultimately lead to cost savings and improved operational performance.

Leave a Reply