Fix today. Protect forever.

Secure your devices with the #1 malware removal and protection software

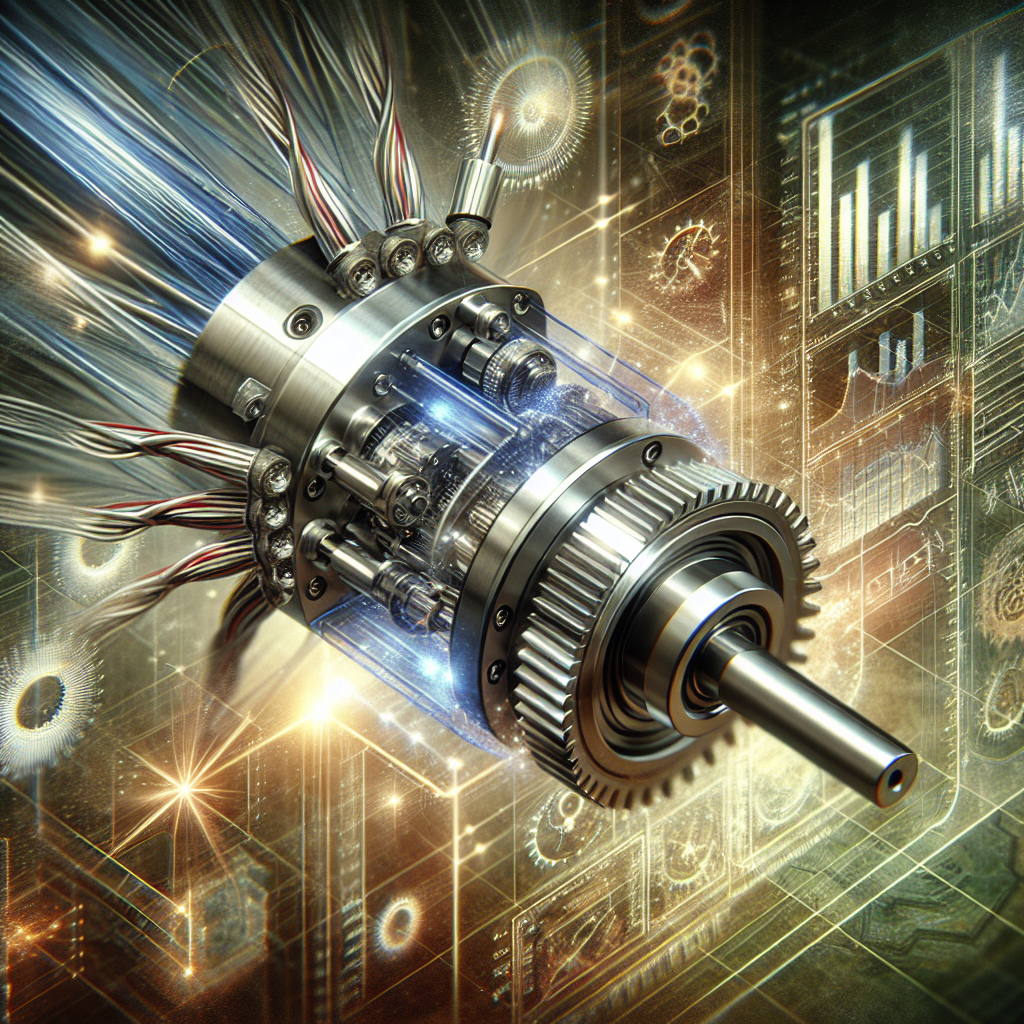

Spindle motors are a crucial component in various industrial applications, particularly in the manufacturing sector. These motors are responsible for driving the rotation of a spindle, which is used to hold and rotate cutting tools, grinding wheels, or other implements in machining processes. The efficiency and performance of spindle motors can have a significant impact on the overall productivity and quality of the manufacturing process.

One of the key ways to maximize efficiency in industrial applications is by using high-performance spindle motors. These motors are designed to deliver superior performance, reliability, and precision, making them ideal for demanding machining operations. By investing in high-performance spindle motors, manufacturers can achieve higher levels of productivity, accuracy, and consistency in their operations.

There are several factors that contribute to the high performance of spindle motors. These include the motor’s power rating, speed range, torque output, and overall design and construction. High-performance spindle motors are typically equipped with advanced features such as high-speed bearings, precision balancing, and efficient cooling systems to ensure smooth and reliable operation even under heavy loads and high speeds.

In addition to the design and construction of the motor itself, the integration of advanced control systems and monitoring technologies can further enhance the efficiency and performance of spindle motors. By implementing advanced control algorithms and real-time monitoring systems, manufacturers can optimize the operation of spindle motors, minimize downtime, and prevent costly errors and failures.

Another key factor in maximizing efficiency with high-performance spindle motors is proper maintenance and servicing. Regular maintenance, including lubrication, cleaning, and inspection, is essential to ensure the longevity and performance of spindle motors. Additionally, manufacturers should follow recommended operating procedures and guidelines to prevent overloading, overheating, and other common issues that can affect the efficiency and reliability of spindle motors.

Overall, investing in high-performance spindle motors can greatly benefit manufacturers by improving the efficiency, accuracy, and productivity of their machining operations. By choosing the right spindle motor for their specific application and implementing proper maintenance and monitoring practices, manufacturers can maximize the performance and longevity of their equipment, ultimately leading to increased profitability and competitiveness in the marketplace.

Fix today. Protect forever.

Secure your devices with the #1 malware removal and protection software

Leave a Reply

You must be logged in to post a comment.