Fix today. Protect forever.

Secure your devices with the #1 malware removal and protection software

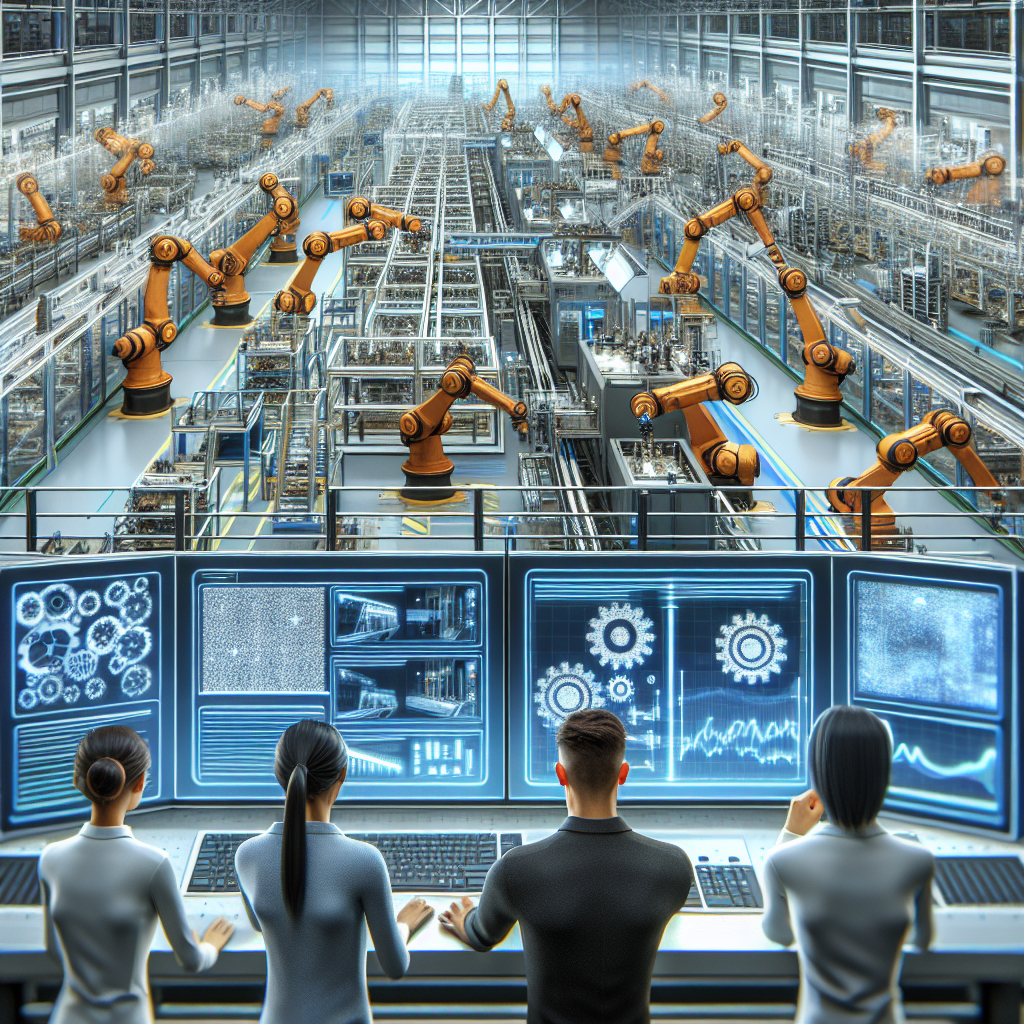

In today’s rapidly evolving manufacturing landscape, efficiency is key to staying competitive and profitable. One way that companies are achieving higher levels of efficiency is through the use of remote monitoring technology. Remote monitoring allows manufacturers to track and analyze data from their equipment and processes in real time, enabling them to identify and address issues quickly, optimize production schedules, and make more informed decisions.

One of the primary benefits of remote monitoring in manufacturing is the ability to proactively detect and address issues before they lead to costly downtime. By monitoring equipment and processes remotely, manufacturers can receive alerts when something is not operating as it should, allowing them to take immediate action to prevent a breakdown or production delay. This proactive approach not only minimizes downtime but also extends the lifespan of equipment, reducing maintenance costs in the long run.

Remote monitoring also enables manufacturers to optimize production schedules and improve overall efficiency. By analyzing real-time data on equipment performance and production processes, companies can identify bottlenecks, inefficiencies, and opportunities for improvement. This data-driven approach allows manufacturers to make informed decisions about how to allocate resources, adjust production schedules, and streamline operations to maximize output and minimize waste.

Furthermore, remote monitoring technology can help manufacturers enhance quality control and ensure compliance with industry regulations. By monitoring key metrics and parameters in real time, companies can identify deviations from set standards and take corrective action to maintain product quality and meet regulatory requirements. This proactive approach not only reduces the risk of defects and recalls but also enhances customer satisfaction and brand reputation.

In addition to operational benefits, remote monitoring technology can also improve the overall safety and security of manufacturing facilities. By monitoring equipment remotely, manufacturers can reduce the need for manual inspections and maintenance, minimizing the risk of accidents and injuries. Furthermore, remote monitoring can help companies detect unauthorized access or suspicious activity in their facilities, enhancing security and protecting valuable assets.

In conclusion, remote monitoring technology is a powerful tool for maximizing efficiency in manufacturing. By providing real-time insights into equipment performance, production processes, and quality control, remote monitoring enables companies to proactively address issues, optimize production schedules, and improve overall operations. As manufacturing becomes increasingly complex and competitive, companies that embrace remote monitoring technology will have a significant advantage in staying ahead of the curve and achieving long-term success.

Fix today. Protect forever.

Secure your devices with the #1 malware removal and protection software

Leave a Reply

You must be logged in to post a comment.