Your cart is currently empty!

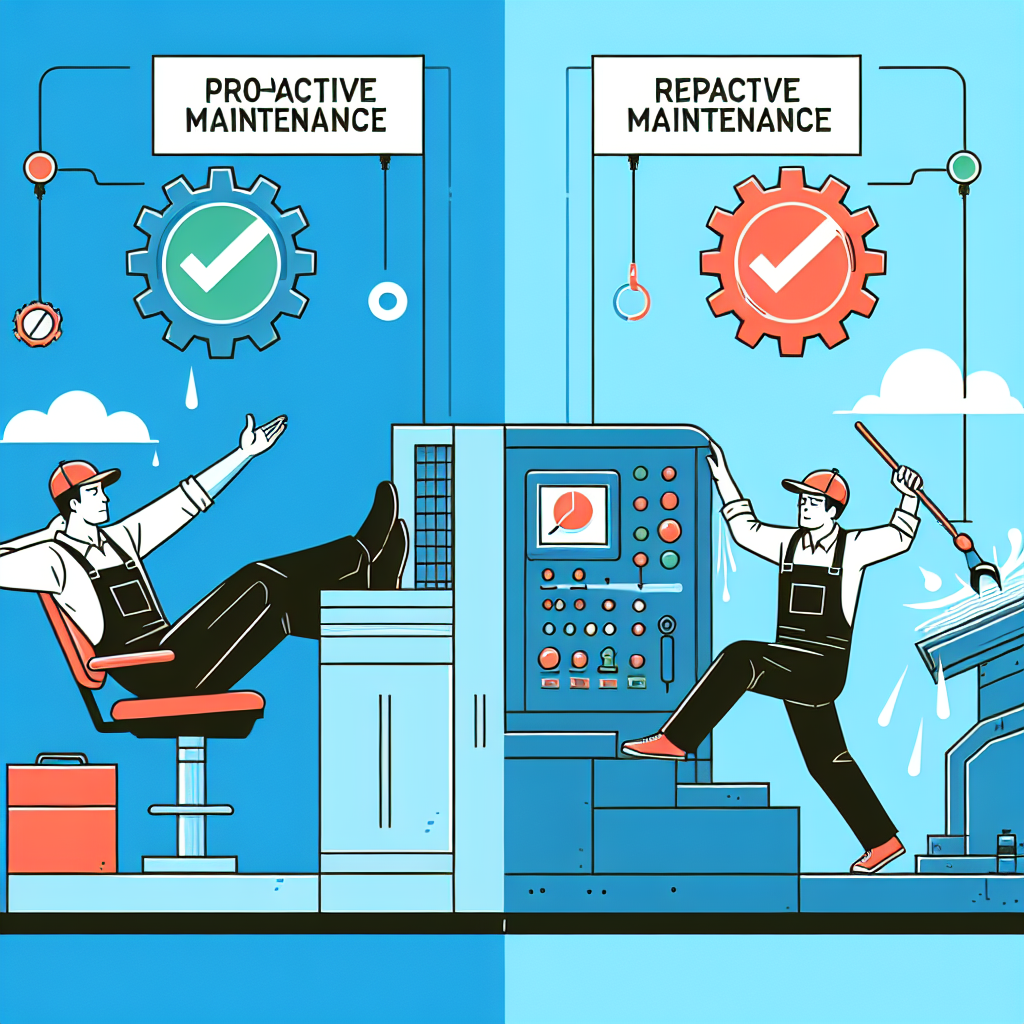

Proactive Maintenance vs. Reactive Maintenance: Why Proactive is the Way to Go

Maintenance is an essential aspect of keeping any machinery or equipment running smoothly and efficiently. However, there are two main approaches to maintenance: proactive maintenance and reactive maintenance. While both have their own benefits, proactive maintenance is widely considered to be the more effective and cost-efficient option. In this article, we will explore the differences between proactive and reactive maintenance and explain why proactive maintenance is the way to go.

Reactive maintenance, also known as breakdown maintenance, is a strategy that involves waiting for a piece of equipment to fail before taking any action. When a breakdown occurs, maintenance personnel are called in to fix the issue and get the equipment up and running again as quickly as possible. While this approach may seem like a quick fix, it can actually end up costing more in the long run. Reactive maintenance can lead to unplanned downtime, costly repairs, and decreased equipment lifespan.

On the other hand, proactive maintenance involves regularly scheduled inspections, preventive maintenance tasks, and predictive maintenance techniques to keep equipment running smoothly and prevent breakdowns before they occur. By identifying and addressing potential issues before they escalate, proactive maintenance can help minimize downtime, extend the lifespan of equipment, and reduce overall maintenance costs.

One of the key advantages of proactive maintenance is that it allows maintenance personnel to plan and prioritize maintenance tasks based on the condition of the equipment, rather than reacting to sudden breakdowns. This can help optimize maintenance schedules, reduce the risk of unexpected downtime, and improve overall equipment reliability. Additionally, proactive maintenance can help identify and address potential safety hazards before they become a serious problem, ensuring a safer work environment for employees.

Another benefit of proactive maintenance is that it can help reduce overall maintenance costs. By regularly inspecting and maintaining equipment, maintenance personnel can identify small issues before they escalate into major problems that require costly repairs or replacements. In the long run, investing in proactive maintenance can help save money by avoiding expensive breakdowns and extending the lifespan of equipment.

In conclusion, proactive maintenance is the way to go when it comes to ensuring the reliability, efficiency, and longevity of equipment. By taking a proactive approach to maintenance, businesses can minimize downtime, reduce maintenance costs, and create a safer work environment for employees. While reactive maintenance may seem like a quick fix, it often leads to increased costs and decreased equipment reliability. Therefore, businesses should prioritize proactive maintenance strategies to maximize the performance and lifespan of their equipment.

Leave a Reply