Your cart is currently empty!

Semiconductor Manufacturing: Processes and Techniques

Semiconductor manufacturing is a complex and intricate process that involves a variety of techniques and processes to produce the tiny electronic components that power our modern world. From smartphones to computers to cars, semiconductors are essential in almost every aspect of our daily lives.

The first step in semiconductor manufacturing is the design and layout of the integrated circuit (IC) on a computer-aided design (CAD) program. This involves designing the circuitry and components of the semiconductor, such as transistors, diodes, and resistors, in a way that will optimize its performance and functionality.

Once the design is complete, the next step is to fabricate the semiconductor on a silicon wafer. This involves a series of complex processes, including photolithography, etching, deposition, and doping. Photolithography is used to transfer the circuit pattern onto the silicon wafer using a mask and ultraviolet light. Etching is then used to remove the unwanted materials from the wafer, while deposition is used to add new materials to the wafer. Doping is the process of introducing impurities into the silicon wafer to change its electrical properties.

After the semiconductor has been fabricated, it undergoes testing and quality control to ensure that it meets the required specifications and standards. This involves testing the functionality, performance, and reliability of the semiconductor through various tests, such as electrical testing, thermal testing, and stress testing.

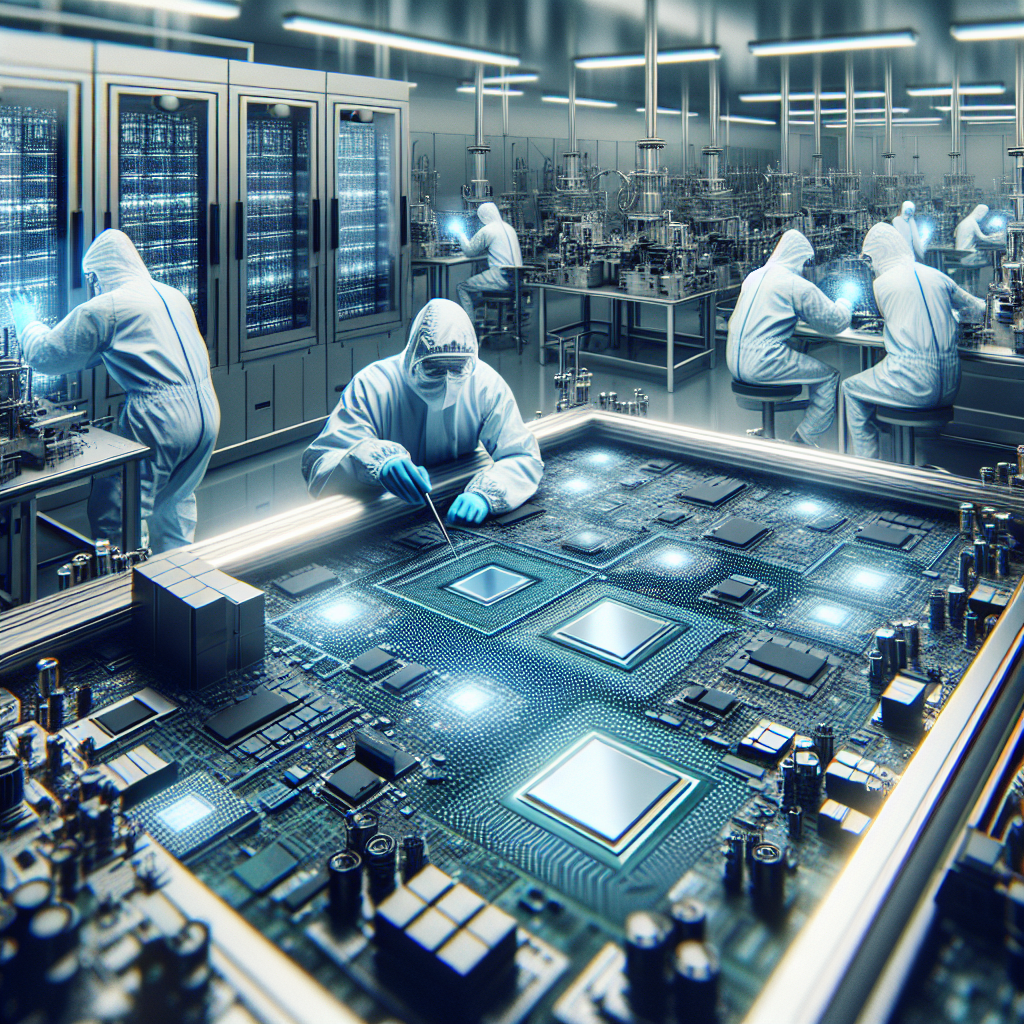

One of the key techniques used in semiconductor manufacturing is cleanroom technology. Cleanrooms are specially designed environments that are free from dust, particles, and contaminants that could damage the semiconductor during the manufacturing process. Cleanrooms are equipped with air filtration systems, ionizers, and cleanroom suits to ensure that the semiconductor is produced in a controlled and clean environment.

Another important technique in semiconductor manufacturing is wafer bonding. Wafer bonding is the process of joining two or more wafers together to create a single semiconductor device. This technique allows for the integration of different materials and components on a single chip, which can improve the performance and functionality of the semiconductor.

Overall, semiconductor manufacturing is a complex and sophisticated process that requires precision, expertise, and advanced technology. By utilizing a variety of techniques and processes, semiconductor manufacturers are able to produce high-quality and high-performance semiconductors that power the devices and technologies that drive our modern world.

Leave a Reply