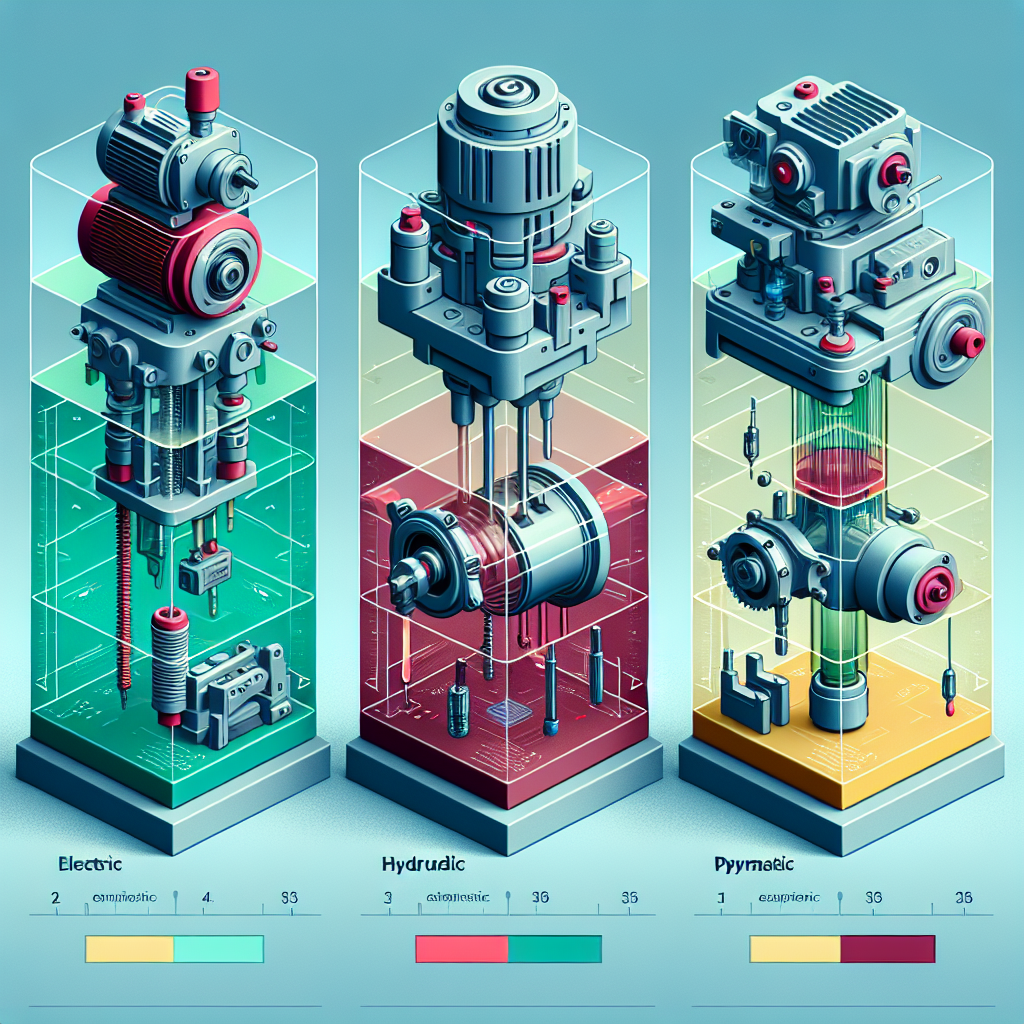

Actuators are essential components in a wide range of industrial and commercial applications, from robotics to HVAC systems. These devices are responsible for converting electrical signals into mechanical movement, allowing for precise control of various systems.

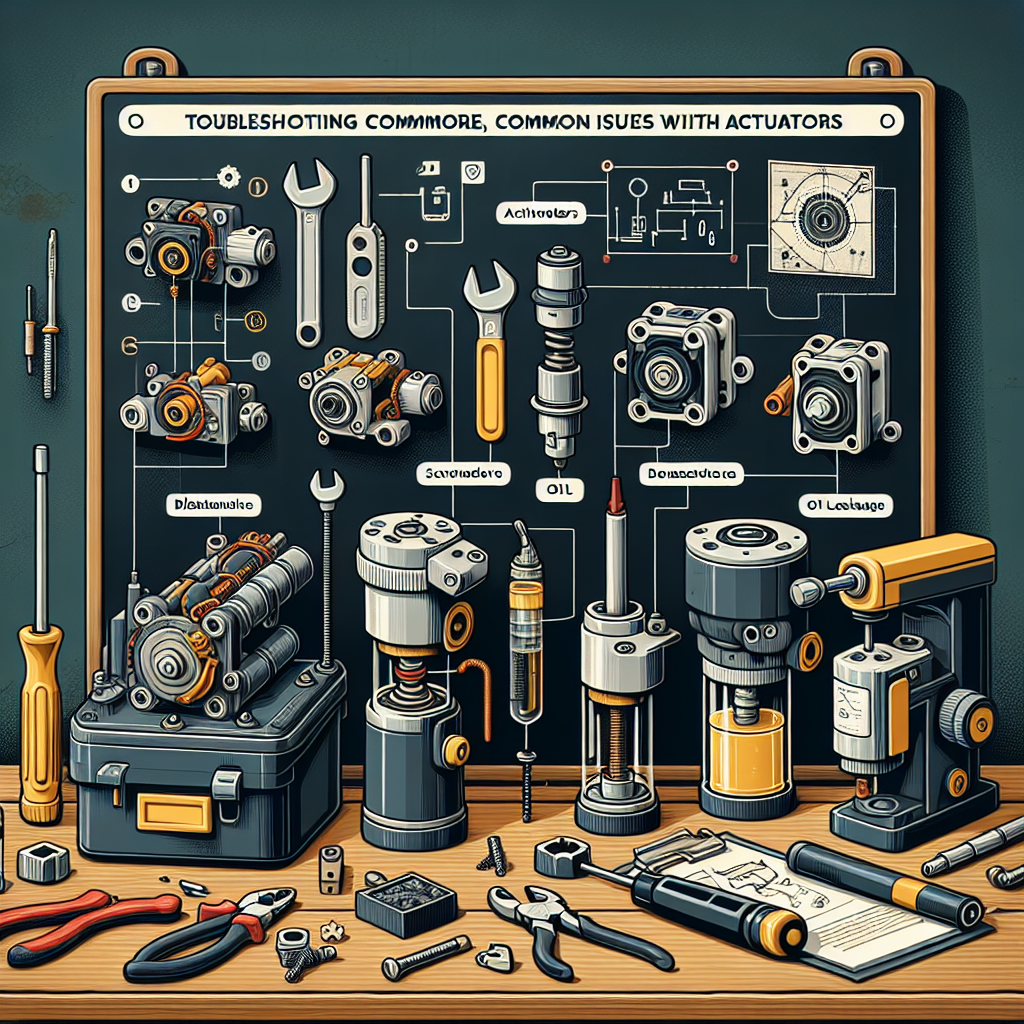

However, like any mechanical device, actuators can experience issues that may hinder their performance. In this article, we will discuss some common problems that may arise with actuators and provide some tips and tricks for troubleshooting and resolving these issues.

1. Inconsistent movement: One of the most common issues with actuators is inconsistent movement, where the actuator may move too slowly, too quickly, or fail to move at all. This can be caused by a variety of factors, such as low voltage, mechanical obstructions, or worn out components.

To troubleshoot this issue, start by checking the voltage supplied to the actuator. Ensure that it is within the recommended range specified by the manufacturer. If the voltage is correct, check for any obstructions that may be preventing the actuator from moving smoothly. Inspect the actuator for any signs of wear or damage, such as broken gears or worn out bearings, and replace any faulty components.

2. Noisy operation: Another common issue with actuators is noisy operation, which can be caused by friction between moving parts, loose components, or worn out bearings. This can not only be annoying but also indicate potential damage to the actuator.

To troubleshoot noisy operation, start by lubricating the moving parts of the actuator to reduce friction. Tighten any loose components and ensure that all fasteners are securely in place. If the noise persists, inspect the bearings for signs of wear or damage and replace them if necessary.

3. Overheating: Actuators can also overheat due to prolonged use or insufficient cooling. Overheating can lead to decreased performance and even damage to the actuator if left unresolved.

To troubleshoot overheating, ensure that the actuator is not being overloaded or operated beyond its rated capacity. Provide adequate cooling by installing a fan or heat sink to dissipate heat generated during operation. If the actuator continues to overheat, consider reducing the load or upgrading to a higher-rated actuator.

4. Erratic movement: Erratic movement of an actuator can be caused by electrical issues, such as signal interference or incorrect wiring. This can result in the actuator moving unpredictably or failing to respond to commands.

To troubleshoot erratic movement, check the wiring connections to ensure they are secure and properly connected. Inspect the electrical signals being sent to the actuator for any interference or noise that may be affecting its operation. Consider using shielded cables or isolating the actuator from other electrical components to minimize interference.

In conclusion, troubleshooting common issues with actuators requires a systematic approach to identify and resolve the underlying causes. By following the tips and tricks outlined in this article, you can effectively troubleshoot and resolve issues with actuators to ensure optimal performance and reliability in your systems.