Your cart is currently empty!

Tag: Actuators

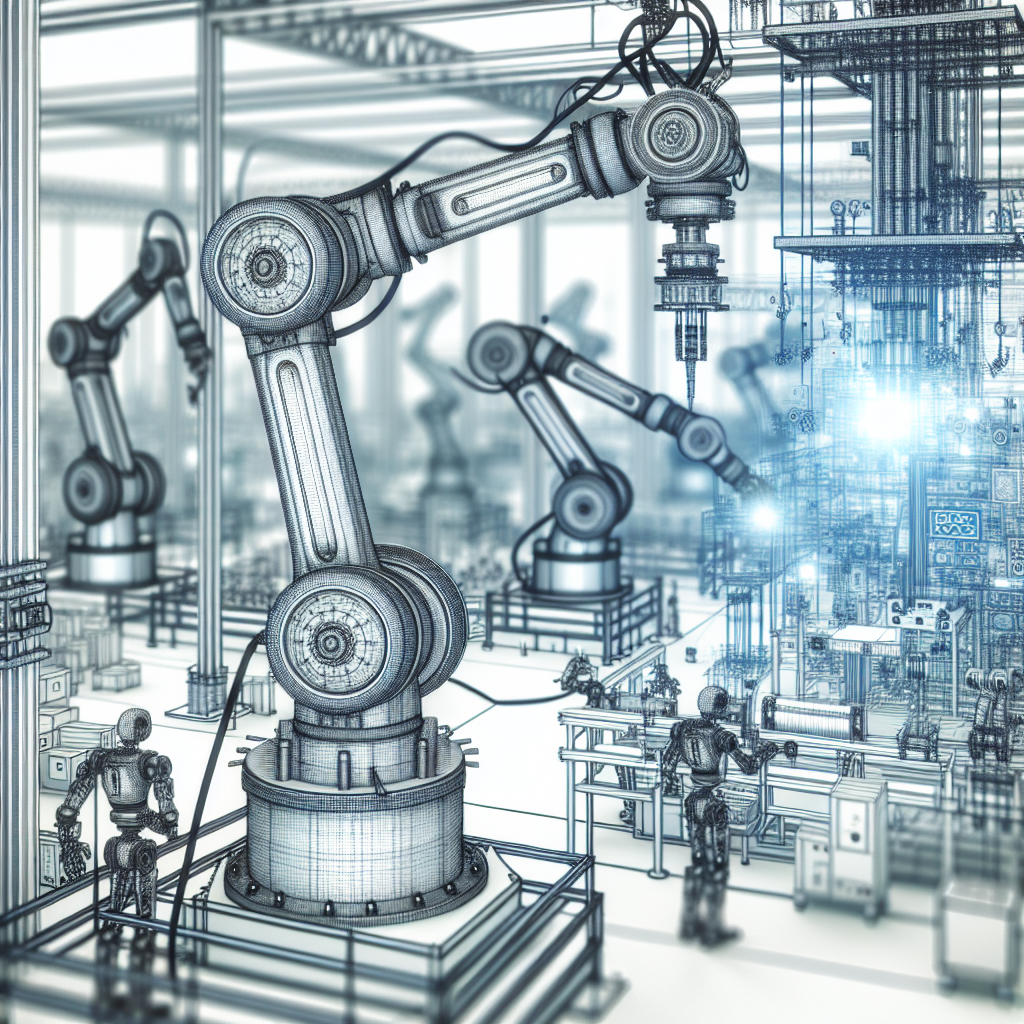

Common Applications of Actuators in Robotics and Manufacturing

Actuators are essential components in both robotics and manufacturing industries. These devices are responsible for converting energy into mechanical motion, allowing machines to perform various tasks. Actuators play a crucial role in controlling the movement of robotic arms, conveyor belts, and other automated systems. In this article, we will discuss some common applications of actuators in robotics and manufacturing.One of the most common applications of actuators in robotics is in the control of robotic arms. These arms are used in a wide range of industries, including automotive, electronics, and healthcare. Actuators are responsible for controlling the movement of the robotic arm, allowing it to pick up and manipulate objects with precision. By using actuators, robotic arms can perform tasks that require dexterity and accuracy, such as assembling components or performing delicate surgical procedures.

Another common application of actuators in robotics is in the control of grippers and end effectors. Grippers are used to grasp and hold objects, while end effectors are used to perform specific tasks, such as welding or drilling. Actuators are used to control the opening and closing of grippers and the movement of end effectors, allowing robots to carry out complex tasks with ease.

In the manufacturing industry, actuators are used in a wide range of applications, including controlling conveyor belts, valves, and robotic welding arms. Conveyor belts are used to transport materials and products throughout a manufacturing facility. Actuators are used to control the speed and direction of the conveyor belt, allowing for efficient and precise movement of materials.

Valves are used to control the flow of liquids and gases in manufacturing processes. Actuators are used to open and close valves, regulating the flow of materials and ensuring that production runs smoothly. Actuators are also used in robotic welding arms, which are used to weld metal components together. By using actuators, manufacturers can automate the welding process, increasing efficiency and accuracy.

Overall, actuators are essential components in both robotics and manufacturing industries. These devices play a crucial role in controlling the movement of robotic arms, grippers, conveyor belts, and other automated systems. By using actuators, manufacturers can increase efficiency, accuracy, and productivity in their operations. As technology continues to advance, the applications of actuators in robotics and manufacturing will only continue to grow.

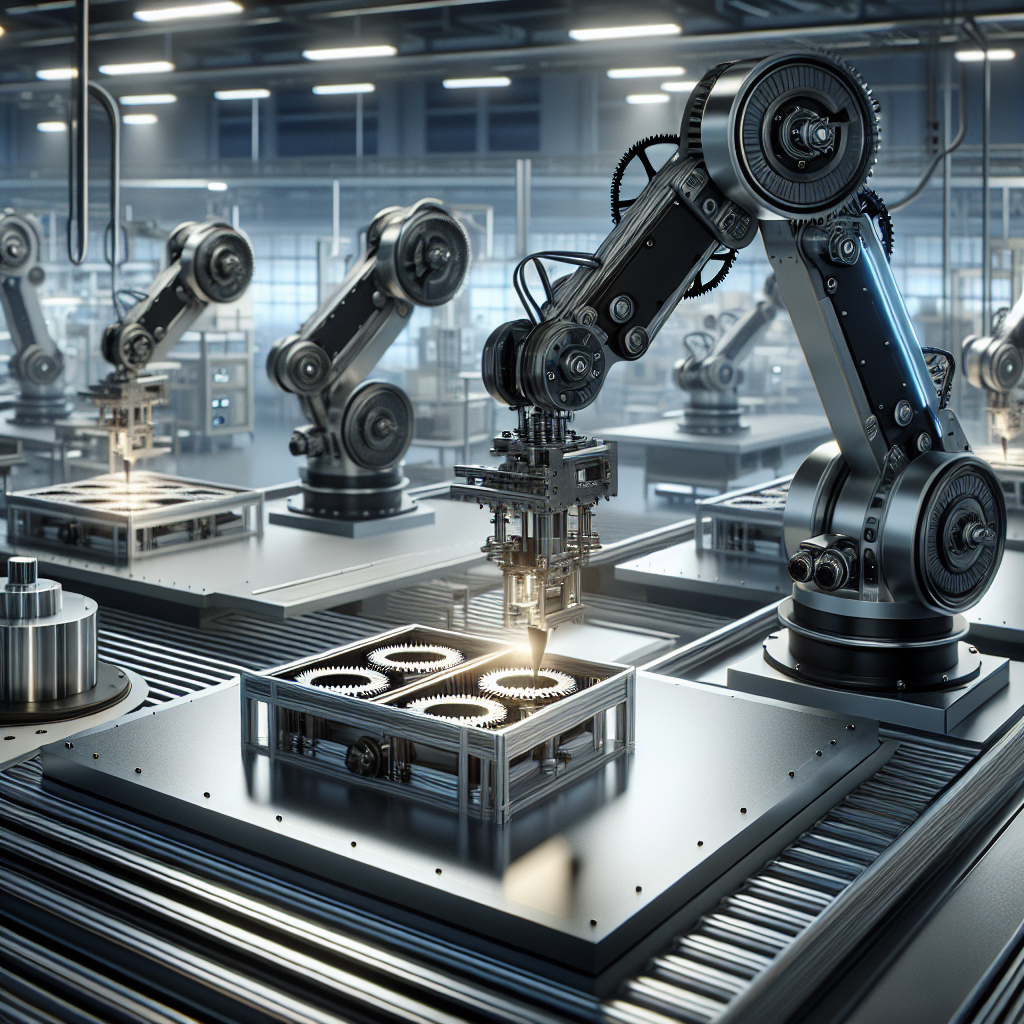

The Future of Actuators: Emerging Trends and Technologies

Actuators are essential components in a wide range of industries, from robotics to aerospace to automotive. These devices are responsible for converting electrical signals into physical movements, allowing machines to perform a variety of functions. As technology continues to advance, the future of actuators looks promising, with emerging trends and technologies poised to revolutionize the industry.One of the most exciting developments in the world of actuators is the rise of smart actuators. These devices are equipped with sensors and microprocessors that allow them to gather data and make decisions autonomously. This level of intelligence enables actuators to adapt to changing conditions in real-time, improving efficiency and performance. Smart actuators are already being used in applications such as self-driving cars and industrial robots, and their popularity is expected to grow in the coming years.

Another trend that is shaping the future of actuators is the increased use of 3D printing technology. This manufacturing technique allows for the production of complex and customized actuators at a lower cost and faster pace than traditional methods. 3D printing also enables the creation of actuators with intricate designs and shapes that were previously impossible to achieve, opening up new possibilities for innovation in the industry.

Furthermore, the development of new materials is driving advancements in actuator technology. Materials such as shape-memory alloys and electroactive polymers are revolutionizing the way actuators operate, offering improved performance and durability. These materials can be used to create actuators that are lighter, more energy-efficient, and more responsive than ever before.

In addition to these trends, the integration of artificial intelligence and machine learning technologies is also set to have a significant impact on the future of actuators. By harnessing the power of AI, actuators can be optimized for specific tasks and environments, leading to more precise and efficient operation. AI-driven actuators can also learn from their experiences and adapt their behavior over time, making them even more versatile and adaptable.

Overall, the future of actuators is bright, with emerging trends and technologies driving innovation and pushing the boundaries of what is possible. As industries continue to evolve and demand for more advanced and efficient actuators grows, we can expect to see even more exciting developments in the years to come. Whether it’s smart actuators, 3D printing, new materials, or AI integration, the future of actuators is sure to be full of groundbreaking advancements that will shape the way we interact with machines and technology.

How Actuators are Revolutionizing the Industrial Automation Industry

Actuators are devices that convert various forms of energy into mechanical motion. They play a crucial role in the field of industrial automation by enabling machines to perform tasks with precision and efficiency. From controlling valves and switches to moving heavy machinery, actuators are revolutionizing the way industries operate.One of the key benefits of actuators in industrial automation is their ability to improve the efficiency and accuracy of manufacturing processes. By automating tasks that were previously done manually, actuators can significantly reduce the risk of human error and increase productivity. This is particularly important in industries where precision and consistency are critical, such as in the automotive and aerospace sectors.

Actuators also play a vital role in improving safety in industrial settings. By automating dangerous or hazardous tasks, actuators can help protect workers from potential injuries and accidents. For example, in the oil and gas industry, actuators are used to control valves and prevent leaks, reducing the risk of environmental damage and ensuring the safety of workers.

Furthermore, actuators are helping industries meet the growing demand for sustainability and energy efficiency. By optimizing the use of resources and reducing waste, actuators can help industries reduce their carbon footprint and lower operating costs. For example, actuators can be used to control the flow of materials in a manufacturing process, ensuring that only the necessary amount is used, thus minimizing waste.

In addition, actuators are enabling industries to adapt to changing market demands and technological advancements. With the rise of Industry 4.0 and the Internet of Things (IoT), actuators are becoming smarter and more interconnected, allowing machines to communicate with each other and make real-time adjustments. This level of automation and connectivity is revolutionizing the way industries operate, leading to increased efficiency, flexibility, and competitiveness.

In conclusion, actuators are playing a crucial role in revolutionizing the industrial automation industry. By improving efficiency, accuracy, safety, and sustainability, actuators are helping industries meet the challenges of the modern world and stay ahead of the competition. As technology continues to advance, the role of actuators in industrial automation will only become more significant, paving the way for a more efficient and sustainable future.

The Evolution of Actuators: From Mechanical to Smart Systems

Actuators are essential components in various industrial and consumer products, responsible for converting energy into mechanical motion. Over the years, there has been a significant evolution in the design and functionality of actuators, moving from simple mechanical systems to more sophisticated and intelligent smart systems.The earliest actuators were purely mechanical in nature, relying on basic principles of physics to generate motion. These actuators were typically powered by pneumatic, hydraulic, or electric sources and were limited in their capabilities. They were often bulky, noisy, and required frequent maintenance.

As technology advanced, so did the design of actuators. The development of more efficient and compact materials, such as piezoelectric and shape memory alloys, allowed for the creation of smaller and more precise actuators. These advancements led to the creation of micro-actuators, which are used in a wide range of applications, from medical devices to consumer electronics.

One of the most significant advancements in actuator technology has been the integration of smart systems. Smart actuators are equipped with sensors, processors, and communication capabilities, allowing them to monitor and adjust their performance in real-time. This level of intelligence enables actuators to adapt to changing conditions, optimize energy consumption, and communicate with other devices in a network.

Smart actuators have revolutionized industries such as robotics, aerospace, and automotive, where precision and efficiency are critical. In robotics, for example, smart actuators enable robots to perform complex tasks with greater accuracy and speed. In aerospace, smart actuators are used in aircraft control systems to improve safety and performance. And in automotive, smart actuators are utilized in advanced driver-assistance systems to enhance vehicle control and safety.

The evolution of actuators from mechanical to smart systems has opened up a world of possibilities for innovation and advancement in various industries. With continued research and development, we can expect to see even more advanced and intelligent actuators in the future, further enhancing the capabilities of machines and devices.

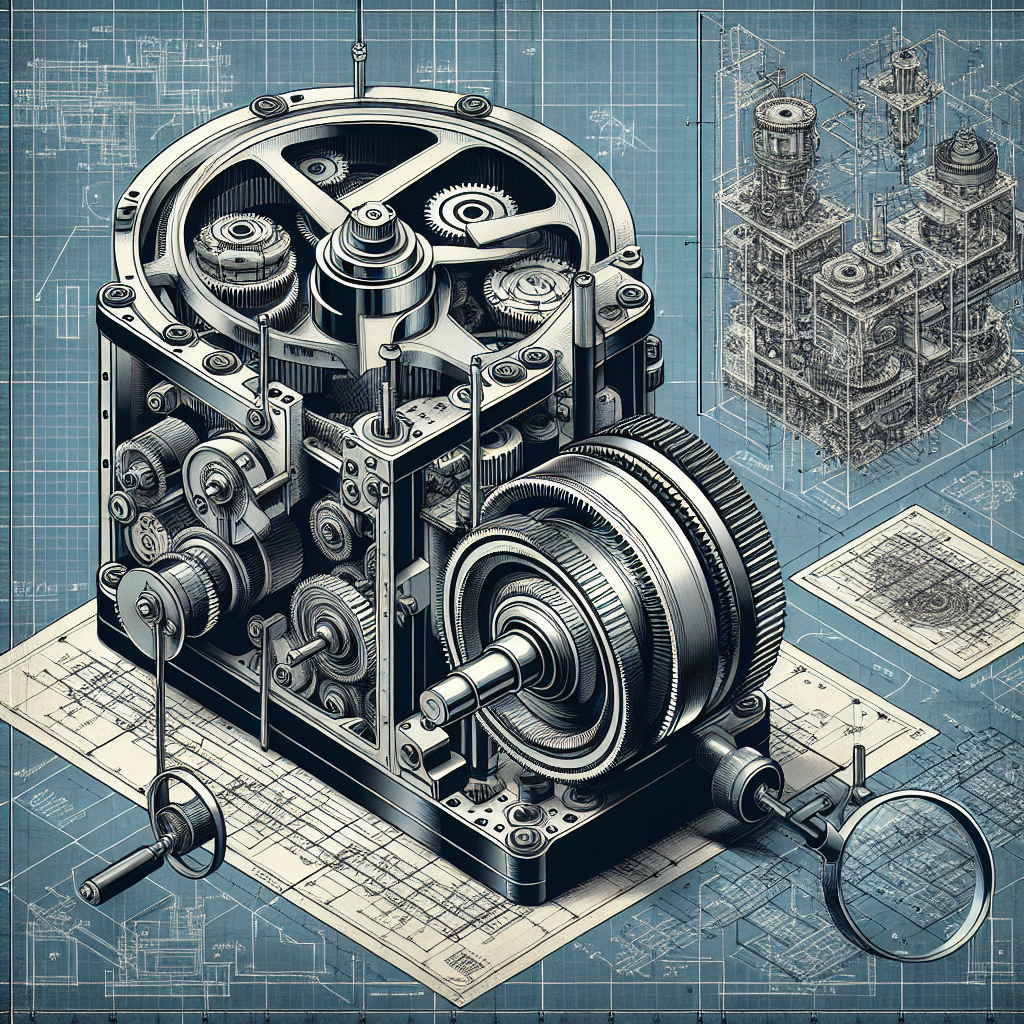

The Role of Actuators in Modern Technology: A Comprehensive Guide

Actuators are an essential component in today’s modern technology, playing a crucial role in the operation of various devices and systems. From robotics to automotive engineering, actuators are used to convert electrical signals into mechanical motion, allowing for precise control and automation.Actuators can be found in a wide range of applications, including industrial machinery, medical devices, aerospace systems, and consumer electronics. They are used to move, position, and control various components within a system, enabling it to perform specific tasks with accuracy and efficiency.

One of the key benefits of actuators is their ability to provide precise and repeatable motion control. This is particularly important in applications where accuracy is critical, such as in medical devices or robotic systems. Actuators can be programmed to move with a high degree of precision, ensuring that tasks are completed with consistency and reliability.

In the field of robotics, actuators play a vital role in enabling machines to perform complex tasks with dexterity and speed. Electric actuators, hydraulic actuators, and pneumatic actuators are commonly used in robotic systems to provide the necessary motion control for tasks such as picking and placing objects, welding, and assembly.

In the automotive industry, actuators are used in a variety of applications, including power steering systems, throttle control, and engine valves. By using actuators, automotive engineers can design vehicles that are more efficient, reliable, and responsive to driver input.

Actuators are also used in the field of aerospace engineering, where they are employed in aircraft control systems, landing gear mechanisms, and satellite deployment systems. By using actuators, aerospace engineers can ensure that aircraft and spacecraft operate safely and efficiently, even in the most challenging environments.

In consumer electronics, actuators are used in devices such as smartphones, tablets, and digital cameras to provide haptic feedback, adjust focus, and control zoom functions. Actuators are also used in virtual reality systems to provide a more immersive experience for users.

Overall, actuators play a crucial role in modern technology, enabling devices and systems to perform a wide range of functions with precision and efficiency. As technology continues to advance, the demand for actuators is expected to grow, driving innovation and new applications in various industries. Whether it’s in robotics, automotive engineering, aerospace systems, or consumer electronics, actuators will continue to play a vital role in shaping the future of technology.

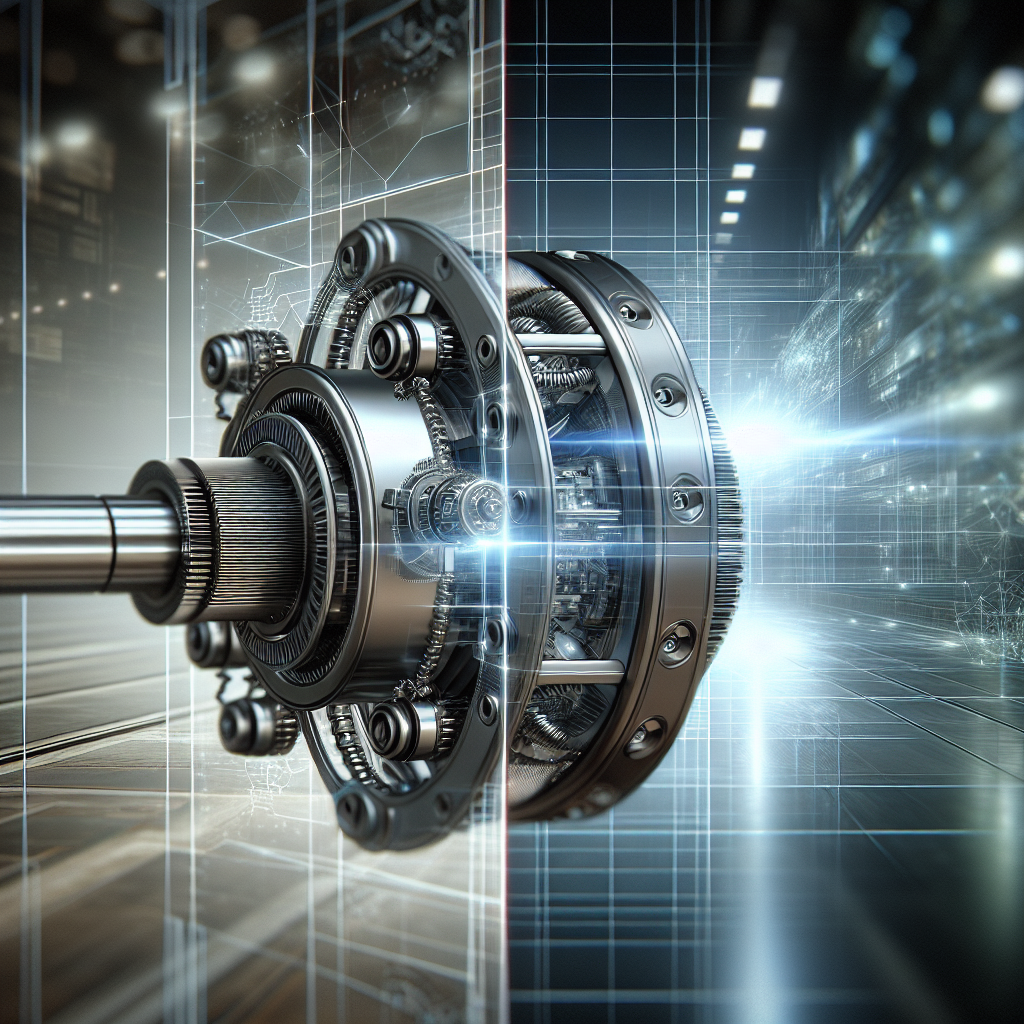

Understanding the Basics of Actuators: What They Are and How They Work

Actuators are essential components in a wide range of mechanical systems, from simple household appliances to complex industrial machinery. Understanding how actuators work is crucial for anyone working with these systems, as they play a key role in controlling movement and positioning.So, what exactly are actuators? In simple terms, actuators are devices that convert energy into motion. They are used to move or control a mechanism or system, typically by converting electrical, hydraulic, or pneumatic energy into mechanical motion. Actuators can be found in a variety of forms, including electric motors, hydraulic cylinders, and pneumatic pistons.

One common type of actuator is the electric motor. Electric motors convert electrical energy into rotational motion, which can be used to drive a variety of mechanical systems. Electric motors are widely used in everything from household appliances like washing machines and fans to industrial equipment like conveyor belts and pumps.

Hydraulic actuators, on the other hand, use hydraulic fluid to generate motion. Hydraulic actuators typically consist of a piston or cylinder that is moved by the pressure of the hydraulic fluid. These actuators are commonly used in heavy-duty applications where high force and precision are required, such as in construction equipment and aerospace systems.

Pneumatic actuators operate similarly to hydraulic actuators but use compressed air instead of hydraulic fluid. Pneumatic actuators are often used in applications where rapid movement and high-speed operation are required, such as in robotics and automation systems.

Regardless of the type of actuator, the basic principle behind their operation remains the same. When energy is applied to the actuator, it generates motion that can be used to control the position or movement of a mechanical system. Actuators can be controlled manually, through the use of switches or levers, or automatically, using sensors and electronic control systems.

In conclusion, actuators are essential components in a wide range of mechanical systems, playing a crucial role in controlling movement and positioning. By understanding the basics of how actuators work, you can better design and operate mechanical systems that rely on these devices. Whether you are working with household appliances or industrial machinery, a solid understanding of actuators is essential for ensuring the smooth and efficient operation of your systems.

How Actuators are Revolutionizing the Healthcare Industry

Actuators are a crucial component in many industries, including healthcare. These devices are responsible for converting energy into motion, making them essential for a wide range of applications in medical devices and equipment. From robotic surgery to prosthetic limbs, actuators are revolutionizing the healthcare industry in countless ways.One of the most significant ways actuators are impacting healthcare is in the field of robotic surgery. Surgeons are using robotic systems equipped with advanced actuators to perform minimally invasive procedures with greater precision and control. These actuators allow for more delicate movements and finer adjustments than human hands, leading to improved outcomes for patients. Robotic surgery has the potential to reduce recovery times, minimize scarring, and increase the success rate of complex procedures.

Actuators are also playing a vital role in the development of prosthetic limbs. By utilizing actuators to mimic the movements of natural muscles, engineers are creating prosthetics that are more lifelike and functional than ever before. These advanced actuators enable amputees to regain mobility and independence, improving their quality of life and overall well-being.

In addition to surgical and prosthetic applications, actuators are being used in a variety of other healthcare devices and equipment. For example, actuators are used in automated drug delivery systems to ensure precise dosages are administered to patients. They are also integral components in medical imaging equipment, such as MRI machines and ultrasound devices, where precise movements are necessary for accurate diagnoses.

Furthermore, actuators are being incorporated into wearable devices and exoskeletons to assist individuals with mobility impairments. These devices use actuators to provide support and assistance with movement, allowing users to perform everyday tasks with greater ease and independence.

Overall, actuators are revolutionizing the healthcare industry by enabling advancements in surgical procedures, prosthetics, drug delivery systems, imaging equipment, and mobility assistance devices. As technology continues to advance, the potential for actuators to improve patient outcomes, enhance quality of life, and drive innovation in healthcare is limitless. The future of healthcare is being shaped by the power of actuators, and the possibilities for their use in medical applications are truly endless.

The Future of Actuators: Trends and Innovations to Watch

Actuators are a critical component in a wide range of industries, from robotics to manufacturing to aerospace. These devices are responsible for converting energy into motion, allowing machines and systems to perform a variety of tasks. As technology continues to advance, the future of actuators is shaping up to be an exciting one, with a number of trends and innovations on the horizon.One of the key trends in the world of actuators is the move towards more compact and lightweight designs. As industries look for ways to increase efficiency and reduce costs, actuators that are smaller and lighter are becoming increasingly important. This trend is being driven by advancements in materials science, as well as improvements in manufacturing processes.

Another trend to watch in the world of actuators is the increasing use of smart and connected devices. As the Internet of Things (IoT) continues to grow, actuators are being integrated with sensors and other technologies to create more intelligent and responsive systems. This allows for greater automation and control, as well as improved monitoring and maintenance capabilities.

Innovations in actuators are also being driven by developments in fields such as artificial intelligence and machine learning. These technologies are enabling actuators to learn and adapt to their environments, making them more efficient and effective. This can lead to improved performance and reliability in a wide range of applications.

One area where actuators are likely to see significant innovation is in the field of soft robotics. Soft actuators, which are made from flexible materials and mimic the movement of natural muscles, are opening up new possibilities for robotics and prosthetics. These actuators are more versatile and adaptable than traditional rigid actuators, and are being used in a variety of applications, from medical devices to wearable technology.

Overall, the future of actuators looks promising, with a number of exciting trends and innovations on the horizon. From compact and lightweight designs to smart and connected devices to soft robotics, the possibilities for actuators are only limited by our imagination. As technology continues to advance, we can expect to see even more groundbreaking developments in the world of actuators in the years to come.

The Impact of Actuators on Smart Home Technology

Smart home technology has revolutionized the way we live, making our homes more efficient, convenient, and secure. One of the key components of smart home technology that has had a significant impact on its development is actuators. Actuators are devices that convert energy into motion, allowing them to control various systems and devices in a smart home.Actuators play a crucial role in smart home technology by enabling the automation of tasks and the remote control of devices. They can be found in a wide range of smart home devices, from thermostats and door locks to lighting and window shades. By using actuators, homeowners can easily adjust settings, monitor their home remotely, and create personalized schedules for their devices.

One of the main benefits of actuators in smart home technology is their ability to improve energy efficiency. For example, smart thermostats use actuators to control the heating and cooling systems in a home, allowing homeowners to optimize their energy usage and reduce their utility bills. Similarly, actuators in smart lighting systems can adjust the brightness and color of lights based on the time of day or the homeowner’s preferences, helping to save energy and create a more comfortable living environment.

Actuators also enhance the security of a smart home by enabling the remote control of door locks, garage doors, and security cameras. Homeowners can use their smartphones or other devices to lock or unlock doors, monitor their property, and receive alerts about suspicious activity. This gives homeowners peace of mind knowing that their home is secure, even when they are away.

Furthermore, actuators make smart home technology more convenient and user-friendly. By automating tasks such as adjusting the thermostat, turning on lights, or opening and closing window shades, homeowners can save time and effort. Actuators also allow for the customization of settings and the creation of personalized routines, making it easier for homeowners to tailor their smart home technology to their specific needs and preferences.

In conclusion, actuators have had a significant impact on the development and functionality of smart home technology. By enabling automation, remote control, energy efficiency, security, and convenience, actuators have transformed the way we interact with our homes and the devices within them. As smart home technology continues to evolve, actuators will play an increasingly important role in creating smarter, more efficient, and more secure homes for homeowners around the world.