Price: $420.00

(as of Dec 25,2024 01:24:56 UTC – Details)

Product Description

4 AXIS DDCS-EXPERT Offline Standalone Motion Controller

Package include:

1 x 4 Axis CNC Offline stand alone Controller DDCS-EXPERT

1 x 4 Axis 100 Pulse Pendant Handwheel MPG with Emergency Stop with plug

1 x 4GB USB Flash drive

1 x USB Extension Cable

Pdf. user manual (If you have not received the user manual at Amazon Message Center from us,please message us)

Introduction

The DDCS Expert is a 4 axis motion controller for open or close stepper and servo systems with 7 inch LCD full color display screen. The highest output pulse per axis is 1MHz.

The users can self-define the functional keys. This controller supports multiple spindle mode, support straight Tool Magazine, gantry type Magazine, disk type magazine. The Operation system interface even though very comprehensive, can be learned in very short time.

The DDCS Expert numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. Reliable control and easy operation.

The internal operating system is Linux based.

The DDCS Expert can be used for many styles and types of CNC machines. Lathes, Routers, Pick&Place and Mills, lathe and cutters are just a few examples. The DDCS Expert operates as a Stand Alone system without the need of a computer.

DDCS-Expert Brief technical feature:

Features

1) Max. 5 Axis,if you choose 4-Axis version,then only supports 4 Axis;1MHz output frequency for each axis;2-4 Axis linear interpolation,any 2 axis circular interpolation;

2) 7 inch full color display screen; resolution ratio: 1024*600, 40 operation keys;

3) 24 photoelectric isolated digital inputs, 21 photoelectric isolated digital outputs;

4) Analog spindle control 0-10V spindle control, also support PWM Output;

5) Magazine type: Supports multiple spindle mode, support straight Tool Magazine, gantry type Magazine, disk type magazine;

6) Probe Mode: Supprt Floating Probe and Fixed Probe;

7) Backlash compensation methods: direction gap compensation, radius gap compensation, length compensation;

8) Interpolation Algorithm: S type, circular hard algorithem, circular soft algorithm;

9) Language: Chinese, English;

10) Software Alarms: Program Error, operation Error, overtravel Error, Driver Error and so on;11) Network: Support file share and online machining the remote files by Ethernet;

12) Spindle control mode support Multi-speed (3 lines 8 kinds speed), 0-10V Analog output, and servo spindle output;

13) Compatible with standard G-code, support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on;

14) The control system can preview the processing path before machining, and it makes the system more steady, working smoothy and precise;

15) Support high speed machining in continuous Polyline segment, system can choose a most efficient algorithm automatically from different kinds Polyline segment algorithm;

Functional/Performance comparison between DDCS-Expert and DDCSV3.1

More features

16) Support un-limited size file for machining;

17) Support Pause Breakpoint resume, “Power Cut” recovery, Start from the specific line;

18) Support time-lock function;

19) Support 4 kinds operation rights: visitor, operator, admin,super admin;

20) Support function of “Try cutting” (handwheel guiding) and “Single-stage processing mode” and so on;

21) Support the fuction of Back to orignal point

21) The Power Supply for the controller is 24VDC, minimum Current is 0.5A;

22) It can support mm and inch. The default is mm. If you need to set inch as the unit, please set it to imperial units through G20 code.

23) If you want to use slave function,you can connect the X-axis or Y-axis to the A-axis,and then the X-axis or Y-axis can slave the A-axis.

Size

The DDCS-Expert is a small box that can fit in a window of a small control box or control cabinet.

Four locking hooks fix this controller from the frame. The dimension you find in above figure.

The front panel is 268mm*172.5mm*5.2mm;

The main body is 268mm*172.5mm*70mm;

To mount the unit in an equipment cabinet,cut the hole 258.4mm*109mm

The front panel consists of 40 user keys and the 7 inch (1024*600) LCD

Needs two power supplies

DDCS-Expert needs two power supplies,Main power is for controller system,IO Port power is for Input and Output and MPG ports. Both power supply is 24VDC,current is 3A.In the System Power input port ,the marked 24V and GND is the main power input ports;

In the IO power input ports,the COM+ and COM- is the power input ports for Input/Output Port and MPG.Please keep in mind,only when the two power supplies are connected correctly the controller can be work properly.

Many new users only give system power,then the limited switches,the relay,and MPG and spindle don’t work at all,then please go to check if you also give power to IO ports.IO power gives the power to all the IO ports,include the Limited switch,Relay,MPG,Etop and all other Input and output Ports,without it,spindle,MPG,Input and Output ports cannot work.

In order to avoid electrical noise it is highly recommended to use two separate 24V power supplies.

It is highly recommended to intall a noise filter.

Probe wiring

We already set the IN09 as “ Probe ” output port.

Some users asked for the wiring methods for the probe with over-strock alarm,here we also set one sample for it.

In the example, we go to the IO port to sent the IN07 as the “Probe signal”,IN06 as “Negative Z-axis hard limit signal”.

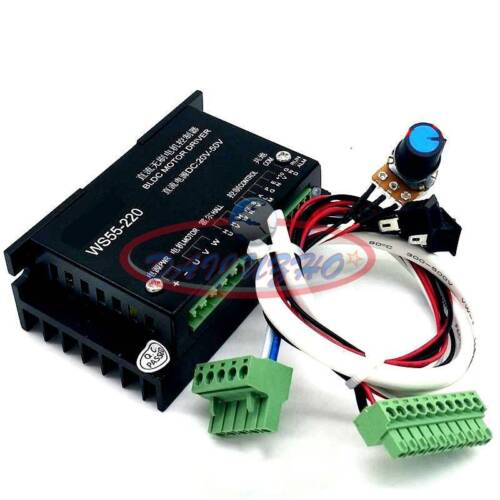

Stepper /Servo Driver Wiring

The stepper / servo control output, the Pulse and Direction signal output voltage is ± 5V

DDCSE Input and Output are the user-defined IO ports, In our example, we already set IN24 as the “ 5th axis servo alarm signal ” input port.

XP+: Pulse Signal Positive Output of the X Axis (5V)

XP-: Pulse Signal Negative Output of the X Axis (5V)

XD+: Direction Signal Positive Output of the X Axis (5V)

XD-: Direction Signal Negative Output of the X Axis (5V)

Limit switch, Home switch and Probe Inputs

DDCSE Input and Output are the user-defined IO ports, In our example, we already set IN12, IN11 and IN10 as the “ axis limit signal ” Input port, and we already set the IN09 as “ Probe ” output port.

Please note that the limit switch type should be NPN Normal Open, and the voltage range is 24VDC.

External Buttons

DDCSE Input and Output are the user-defined IO ports, In our example, we already set IN23 as the “ External Start ” input port, IN22 as the “ External Pause ” input port, and IN21 as “ Extertnal Stop ” input Port.

please choose the external buttons which is 24VD power supply input,then no need an external power supply for them.

Relay Wiring

By Configuration of more Spindle Output ports, the spindle control output terminal offers connections for Start / Stop of Cooling ( M8 / M9 ) and Start / Stop of Lubrication ( M10 / M11 ) and so on.

For example, it can be used for a Relay output port. Following figure shows the wiring methods.

If Relay Power Supply is 24VDC:

DDCS Expert Input and Output are the user-defined IO ports,as our example here,we already set OUT10 as the “Cooling on/off” output port,and we already set the OUT01 as Vacuum valve on/off” output port.

If Relay Power Supply is not 24VDC:

The users need to use an external power supply,then we will provide the Schemat-ics drawing.

The Wiring for the Multi-Speed Spindle

FOR:Spindle Start/Stop-Forw ard Rotation and Stop Output of spindle(OUT21)

COM-: Spindle Output COMMON(Cannot short connect with ACM)

VSO: Analog Output

ACM: Analog Ground

(Connect with Anaog input port of the inverter)

There are 3 parameters related to the Multi-speed spindle:

#079-“Spindle interface type”;Here we need to set it to “ Multi-speed ”

#088 — “Multi-speed section counts”; The section count value range is 2-8, the users can set 2-8 different spindle speed.

#082 — “Max.Spindle Speed”.

The the wiring for the Multi-Speed Spindle as above wiring.

Spindle Wiring

In the Param Page, by #079, we can define the spindle mode.

In Analog Spindle, the speed controlling output terminal can output 0-10V. It can adjust the speed of the spindle by sending the voltage between 0 and 10V to the VFD according the the Spindle Speed Setting.

Controlling the speed of a spindle with a VFD only needs the Start/Stop signal and the 0-10V signal to control the frequency.

FOR port is same wiring methods as the normal Output Ports.

FOR is for spindle forward rotation output or start/stop output;

Analog circuit is isolated with Power supply output,Never short connect the ACM and COM- ( DCM );

If only need the Start and Stop command for the spindle, then just connect FOR output port of the controller with Start input port of the VFD.

The “VSO” and “PWM” only one port is avaiable for one configuration. Use “VSO” port or “PWM” port, the two ports cannot be used at the same time.

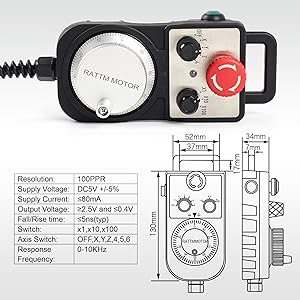

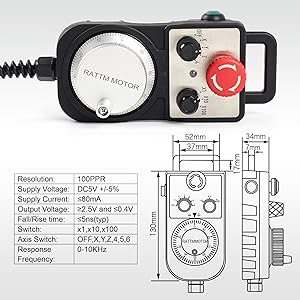

Comes with 4 Axis MPG

The CNC 4 Axis handheld controller MPG Pendant with x1, x10, x100 selectable, with Emergency stop for 4 axis CNC machine

It equipped with our popular machined MPG unit with 4 axis and scale selector,LED indicator also send feed back from the CNC machine to user about the status of the unit.

This handwheel comes with a plug,so it’s “Plug and play”

Features of the MPG

x1, x10, x100 switch

X,Y,Z,4th axis selector switch

LED indicator

With Emergency stop

Extendable high quality shielded cable cord

Magnetic base holder can place anywhere on the machine steel surface

Required 5V+, 150mA, power for MPG

Resolution:100PPR

Supply Current:≤80mA

Response Frequency:0-10KHz

Plug & Play

In order to make the convenient for the users, we already solder the MPG cables to the PIN15 male interface plug,so that you can plug the MPG to the controller directly.

All the input signal COMMON termimal is COM-, not GND; Never short connect GND and COM-;

The MPG need the power from IO power port ( COM+ / COM- ), or the MPG cannot work;

Because of the limit of the pins, if X10 and X100 is not selected, the system just select X1 by default.

With the MPG, and press the “Try Cut” key, the system can change to “Handwheel guiding” mode.

Please Turn the Handwheel to counterclockwise direction, the Try Cut (Handwheel guiding) can be active.

Product: 4-Axis DDCS-EXPERT with MPG; The DDCS-Expert is a small box that can fit in a window of a small control box or control cabinet; Four locking hooks fix this controller from the frame

Introduction: The DDCS Expert numerical control system adopts the ARM and FPGA design framework; ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. The internal operating system is Linux based

Main Features: 7 inch full color display screen; resolution ratio: 1024×600, 40 operation keys; 24 photoelectric isolated digital inputs, 21 photoelectric isolated digital outputs;Analog spindle control 0-10V spindle control, also support PWM Output;Compatible with standard G-code,support popular CAD/CAM software, such as ArtCam, MasterCam, ProE, JDSoft SurfMill, Aspire, Fusion 360 and so on

More Features: Magazine type: Supports multiple spindle mode, support straight Tool Magazine, gantry type Magazine, disk type magazine; Probe Mode: Supprt Floating Probe and Fixed Probe; Backlash compensation methods: direction gap compensation, radius gap compensation, length compensation;The control system can preview the processing path before machining, and it makes the system more steady, working smoothy and precise etc

4 Axis MPG: The MPG Pendant with x1, x10, x100 selectable, with Emergency stop for 4 axis CNC machine;We already solder the MPG cables to the PIN15 male interface plug,so that you can plug the MPG to the controller directly

Applications: The DDCS Expert can be used for many styles and types of CNC engraver machines, Lathes, CNC Router,Carving,Cutting Machine, Pick and Place and Milling Machine, lathe and cutters are just a few examples

Introducing the CNCTOPBAOS 4 Axis Milling Machine CNC Controller! This advanced controller features a 1000KHz Offline Standalone PLC and DDCS Expert Motion Control System, making it perfect for use with CNC routers, lathes, engraving machines, servo motors, and stepper motors.

The CNCTOPBAOS controller also comes equipped with an MPG handwheel, allowing for precise manual control when needed. With its high processing speed and reliable performance, this controller is sure to take your machining projects to the next level.

Whether you’re a hobbyist or a professional machinist, the CNCTOPBAOS 4 Axis Milling Machine CNC Controller is a must-have tool for your workshop. Upgrade your equipment and experience the difference today! #CNC #MillingMachine #CNCController #DDCSExpertMotionControlSystem

#CNCTOPBAOS #Axis #Milling #Machine #CNC #Controller1000KHz #Offline #Standalone #PLCDDCS #Expert #Motion #Control #System #MPG #Handwheel #CNC #RouterLatheEngraving #MachineServoStepper #Motor