Your cart is currently empty!

Tag: Manufacturing

Maximizing Efficiency with Remote Monitoring in Manufacturing

In today’s rapidly evolving manufacturing landscape, efficiency is key to staying competitive and profitable. One way that companies are achieving higher levels of efficiency is through the use of remote monitoring technology. Remote monitoring allows manufacturers to track and analyze data from their equipment and processes in real time, enabling them to identify and address issues quickly, optimize production schedules, and make more informed decisions.One of the primary benefits of remote monitoring in manufacturing is the ability to proactively detect and address issues before they lead to costly downtime. By monitoring equipment and processes remotely, manufacturers can receive alerts when something is not operating as it should, allowing them to take immediate action to prevent a breakdown or production delay. This proactive approach not only minimizes downtime but also extends the lifespan of equipment, reducing maintenance costs in the long run.

Remote monitoring also enables manufacturers to optimize production schedules and improve overall efficiency. By analyzing real-time data on equipment performance and production processes, companies can identify bottlenecks, inefficiencies, and opportunities for improvement. This data-driven approach allows manufacturers to make informed decisions about how to allocate resources, adjust production schedules, and streamline operations to maximize output and minimize waste.

Furthermore, remote monitoring technology can help manufacturers enhance quality control and ensure compliance with industry regulations. By monitoring key metrics and parameters in real time, companies can identify deviations from set standards and take corrective action to maintain product quality and meet regulatory requirements. This proactive approach not only reduces the risk of defects and recalls but also enhances customer satisfaction and brand reputation.

In addition to operational benefits, remote monitoring technology can also improve the overall safety and security of manufacturing facilities. By monitoring equipment remotely, manufacturers can reduce the need for manual inspections and maintenance, minimizing the risk of accidents and injuries. Furthermore, remote monitoring can help companies detect unauthorized access or suspicious activity in their facilities, enhancing security and protecting valuable assets.

In conclusion, remote monitoring technology is a powerful tool for maximizing efficiency in manufacturing. By providing real-time insights into equipment performance, production processes, and quality control, remote monitoring enables companies to proactively address issues, optimize production schedules, and improve overall operations. As manufacturing becomes increasingly complex and competitive, companies that embrace remote monitoring technology will have a significant advantage in staying ahead of the curve and achieving long-term success.

Remote Monitoring: A Game-Changer for Manufacturing Efficiency

In today’s fast-paced manufacturing industry, staying ahead of the competition requires constant innovation and optimization of processes. One of the key technologies that has emerged as a game-changer in this regard is remote monitoring.Remote monitoring involves the use of sensors, cameras, and other devices to track and analyze real-time data from manufacturing equipment and processes. This data is then transmitted to a central system where it can be accessed and analyzed by managers and operators from anywhere in the world.

The benefits of remote monitoring for manufacturing efficiency are numerous. For starters, it allows for real-time visibility into the performance of equipment and processes, enabling managers to quickly identify and address any issues that may arise. This can help to minimize downtime and prevent costly production delays.

Remote monitoring also provides valuable insights into the efficiency of manufacturing processes. By tracking key performance indicators such as cycle times, downtime, and quality metrics, managers can identify areas for improvement and implement targeted strategies to increase productivity and reduce waste.

Furthermore, remote monitoring enables predictive maintenance, allowing manufacturers to proactively address equipment failures before they occur. By monitoring the condition of equipment in real-time and analyzing data patterns, managers can schedule maintenance tasks at optimal times, minimizing unplanned downtime and extending the lifespan of equipment.

In addition to improving efficiency and reducing costs, remote monitoring also enhances safety in the manufacturing environment. By monitoring potentially hazardous processes from a distance, operators can minimize their exposure to dangerous conditions and respond quickly to any emergencies that may arise.

Overall, remote monitoring is revolutionizing the manufacturing industry by providing real-time visibility, insights, and control over production processes. By leveraging this technology, manufacturers can increase efficiency, reduce costs, and stay competitive in an increasingly challenging market. It is clear that remote monitoring is a game-changer for manufacturing efficiency, and companies that embrace this technology are poised for success in the future.

Office of Public Affairs | Justice Department Announces Charges Against China-Based Chemical Manufacturing Companies and Arrests of Executives in Fentanyl Manufacturing

On Friday June 23, 2023 the Justice Department announced the arrest of two individuals and the unsealing of three indictments in the Southern and Eastern Districts of New York charging China-based companies and their employees with crimes related to fentanyl production, distribution, and sales resulting from precursor chemicals. These indictments represent the first prosecutions to charge China-based chemical manufacturing companies and nationals of the People’s Republic of China (PRC) for trafficking fentanyl precursor chemicals into the United States. Specifically, the indictments allege the defendants knowingly manufactured, marketed, sold, and supplied precursor chemicals for fentanyl production in the United States in violation of federal law.

The Office of Public Affairs at the Justice Department has announced significant charges against China-based chemical manufacturing companies involved in the illicit production of fentanyl. Additionally, arrests have been made of executives involved in the manufacturing and distribution of this deadly synthetic opioid.Fentanyl has been a major contributor to the opioid crisis in the United States, causing countless overdose deaths and devastating families and communities. The Justice Department is taking a strong stance against those who are fueling this epidemic by targeting the manufacturers and distributors of this dangerous drug.

The charges and arrests made in this case are a significant step in combatting the flow of illicit fentanyl into the United States and holding those responsible accountable for their actions. The Justice Department is committed to working with international partners to dismantle the illegal drug trade and protect the public from the devastating effects of fentanyl.

Stay tuned for further updates on this important case as the Justice Department continues its efforts to combat the opioid crisis and bring those responsible to justice.

Tags:

- Office of Public Affairs

- Justice Department

- Charges

- China-based

- Chemical manufacturing companies

- Arrests

- Executives

- Fentanyl manufacturing

- Drug trafficking

- Criminal charges

#Office #Public #Affairs #Justice #Department #Announces #Charges #ChinaBased #Chemical #Manufacturing #Companies #Arrests #Executives #Fentanyl #Manufacturing

RULAND MANUFACTURING TCN-05-F Shaft Collar,Locknut,1Pc,0.969-32 In,St 30VT78

RULAND MANUFACTURING TCN-05-F Shaft Collar,Locknut,1Pc,0.969-32 In,St 30VT78

Price : 26.08

Ends on : N/A

View on eBay

Looking for a high-quality shaft collar and locknut for your machinery? Look no further than the RULAND MANUFACTURING TCN-05-F Shaft Collar and Locknut!This 1-piece set is designed to fit a shaft size of 0.969-32 inches, making it perfect for a wide range of applications. Made from durable materials, this collar and locknut are built to last and withstand heavy use.

Don’t settle for inferior products when it comes to your machinery. Trust RULAND MANUFACTURING for all your shaft collar and locknut needs. Order yours today and experience the quality and reliability that RULAND MANUFACTURING is known for. #RulandManufacturing #ShaftCollar #Locknut #MachineryMaintenance

#RULAND #MANUFACTURING #TCN05F #Shaft #CollarLocknut1Pc0.96932 #InSt #30VT78,tcnRULAND MANUFACTURING TCN-08-F Shaft Collar,Locknut,1Pc,1-9/16-18 In,St 30VT81

RULAND MANUFACTURING TCN-08-F Shaft Collar,Locknut,1Pc,1-9/16-18 In,St 30VT81

Price : 39.69

Ends on : N/A

View on eBay

Are you in need of a reliable shaft collar and locknut for your machinery? Look no further than the RULAND MANUFACTURING TCN-08-F Shaft Collar! This high-quality, durable collar is designed for easy installation and a secure fit, ensuring your equipment runs smoothly and efficiently.Made of sturdy materials, this 1-piece collar is built to last and can handle even the toughest working conditions. With a 1-9/16-18 inch size and St 30VT81 construction, you can trust that this collar will provide a strong grip and reliable performance.

Don’t wait any longer to upgrade your machinery with the RULAND MANUFACTURING TCN-08-F Shaft Collar. Order yours today and experience the difference it can make in your operations!

#RULAND #MANUFACTURING #TCN08F #Shaft #CollarLocknut1Pc191618 #InSt #30VT81,tcnThe Zacks Analyst Blog Taiwan Semiconductor Manufacturing, Broadcom, Marvell Technology and Apple

Chicago, IL – January 24, 2025 – Zacks.com announces the list of stocks featured in the Analyst Blog. Every day the Zacks Equity Research analysts discuss the latest news and events impacting stocks and the financial markets. Stocks recently featured in the blog include, Taiwan Semiconductor Manufacturing Company Ltd. TSM, Broadcom Inc. AVGO, Marvell Technology, Inc. MRVL and Apple Inc. AAPL.

Taiwan Semiconductor Manufacturing Company Ltd., better known as TSMC, saw its shares scale northward after posting record fourth-quarter net income, which topped analysts’ projections. The foundry behemoths’ fourth-quarter net profit soared 57% to $374.68 billion from a year earlier, driven by a surge in demand for artificial intelligence (AI) chipsets.

But it’s not the latest quarterly result that propelled its shares higher. The TSMC stock has already gained 91% in the past year with the advent of AI. However, can the TSMC stock sustain this growth and remain a good buy? Let’s see –

While the current quarterly results have boosted the TSMC stock, the long-term growth trajectory depends on the long-term growth prospects. TSMC’s first-quarter revenue guidance of $25 billion to $25.8 billion is 6% higher than expectations, suggesting strong near-term growth. Also, management expects a 20% revenue CAGR over the next five-year period, driven by growth opportunities in AI, 5G smartphones, and high-performance computing.

The rising demand for TSMC’s custom AI chips from Broadcom Inc. and Marvell Technology, Inc. has strengthened its future growth. Meanwhile, Apple Inc. has witnessed a rise in demand for its smartphones that require TSMC’s chips, a positive development for the latter. TSMC’s bright future is also due to the forthcoming launch of their highly efficient 2-nanometer (nm) chips this year, with pre-order demand exceeding 3 and 5nm.

TSMC’s dominant position in the global foundry market means the stock is well-poised to take advantage of the growing opportunities. After all, the semiconductor market worldwide is projected to generate $1.47 trillion in revenues in 2030 from $729 billion in 2022, per SNS Insider. Management mentioned that the U.S. government’s curb on chip sales to China is “manageable.”

Second, the new Stargate AI infrastructure program is expected to be a game changer for the TSMC stock. President Trump intends to allocate $500 billion for AI infrastructure, boosting AI stocks. TSMC stands to benefit as its advanced chips are essential for operating AI data centers.

The Zacks Analyst Blog: Taiwan Semiconductor Manufacturing, Broadcom, Marvell Technology and AppleIn this edition of The Zacks Analyst Blog, we will be taking a closer look at some of the top semiconductor companies in the industry, including Taiwan Semiconductor Manufacturing, Broadcom, Marvell Technology, and Apple.

Taiwan Semiconductor Manufacturing Company (TSMC) is the world’s largest dedicated independent semiconductor foundry, with a market capitalization of over $500 billion. TSMC is a key supplier for companies like Apple, NVIDIA, AMD, and Qualcomm, producing advanced chips for smartphones, PCs, and data centers. The company has been at the forefront of technological innovation, developing cutting-edge processes like 5nm and 3nm for its clients.

Broadcom Inc. is a global technology leader that designs, develops, and supplies a broad range of semiconductor and infrastructure software solutions. Broadcom’s products are used in a wide variety of applications, including networking, storage, and wireless communication. The company has a market capitalization of over $200 billion and a strong track record of revenue growth and profitability.

Marvell Technology Group is a leading provider of semiconductor solutions for data infrastructure, including storage, networking, and connectivity. Marvell’s products are used in a wide range of applications, from cloud data centers to automotive and industrial markets. The company has a market capitalization of over $50 billion and has been growing its revenue and earnings at a rapid pace.

Apple Inc. is one of the most valuable companies in the world, with a market capitalization of over $2 trillion. While Apple is primarily known for its consumer electronics products like the iPhone, iPad, and Mac, the company also designs and manufactures its own custom chips, including the A-series processors used in its devices. Apple has been investing heavily in semiconductor technology, including the recent announcement of its plans to build its own silicon for its Mac computers.

Overall, these companies are at the forefront of semiconductor innovation and are well-positioned to benefit from the growing demand for advanced chips in a wide range of applications. Investors looking for exposure to the semiconductor industry should consider adding these companies to their portfolios.

Tags:

- Zacks Analyst Blog

- Taiwan Semiconductor Manufacturing

- Broadcom

- Marvell Technology

- Apple

- Tech stocks

- Semiconductor industry

- Stock analysis

- Investment opportunities

- Technology companies

#Zacks #Analyst #Blog #Taiwan #Semiconductor #Manufacturing #Broadcom #Marvell #Technology #Apple

Manufacturing PMI® at 49.3%; December 2024 Manufacturing ISM® Report On Business®

New Orders Growing and Backlogs Contracting; Production Growing and Employment Contracting; Supplier Deliveries Slowing; Raw Materials Inventories Contracting; Customers’ Inventories Too Low; Prices Increasing; Exports Unchanged and Imports Contracting

TEMPE, Ariz., Jan. 3, 2025 /PRNewswire/ — Economic activity in the manufacturing sector contracted in December for the ninth consecutive month and the 25th time in the last 26 months, say the nation’s supply executives in the latest Manufacturing ISM® Report On Business®.

The report was issued today by Timothy R. Fiore, CPSM, C.P.M., Chair of the Institute for Supply Management® (ISM®) Manufacturing Business Survey Committee:

“The Manufacturing PMI® registered 49.3 percent in December, 0.9 percentage point higher compared to the 48.4 percent recorded in November. The overall economy continued in expansion for the 56th month after one month of contraction in April 2020. (A Manufacturing PMI® above 42.5 percent, over a period of time, generally indicates an expansion of the overall economy.) The New Orders Index continued in expansion territory for the second month after seven months of contraction, strengthening to 52.5 percent, 2.1 percentage points higher than the 50.4 percent recorded in November. The December reading of the Production Index (50.3 percent) is 3.5 percentage points higher than November’s figure of 46.8 percent. The index returned to expansion after six months in contraction. The Prices Index continued in expansion (or ‘increasing’) territory, registering 52.5 percent, up 2.2 percentage points compared to the reading of 50.3 percent in November. The Backlog of Orders Index registered 45.9 percent, up 4.1 percentage points compared to the 41.8 percent recorded in November. The Employment Index registered 45.3 percent, down 2.8 percentage points from November’s figure of 48.1 percent.

“The Supplier Deliveries Index indicated marginally slower deliveries, registering 50.1 percent, 1.4 percentage points higher than the 48.7 percent recorded in November. (Supplier Deliveries is the only ISM® Report On Business® index that is inversed; a reading of above 50 percent indicates slower deliveries, which is typical as the economy improves and customer demand increases.) The Inventories Index registered 48.4 percent, up 0.3 percentage point compared to November’s reading of 48.1 percent.

“The New Export Orders Index’s ‘unchanged’ reading of 50 percent is 1.3 percentage points higher than the 48.7 percent registered in November. The Imports Index remained in contraction territory in December, registering 49.7 percent, 2.1 percentage points higher than November’s reading of 47.6 percent.”

Fiore continues, “U.S. manufacturing activity contracted again in December, but at a slower rate compared to November. Demand showed signs of improving, while output stabilized and inputs stayed accommodative. Demand analysis includes: the (1) New Orders Index remaining in expansion territory, (2) New Export Orders Index increasing (up 1.3 percentage points and now ‘unchanged’), (3) Backlog of Orders Index slowing its rate of decline but continuing in contraction territory, and (4) Customers’ Inventories Index dropping into ‘too low’ territory. Output (measured by the Production and Employment indexes) was positive; factory output stabilized compared to November, indicating that panelists’ companies are executing to plan. Employment contracted as final head-count adjustments were likely taken to prepare for 2025. Inputs — defined as supplier deliveries, inventories, prices and imports — generally continued to accommodate future demand growth, with inventories and imports improving marginally (though remaining in contraction), prices increasing and supplier deliveries marginally slowing.

“Demand improved, production execution met November’s performance (and companies’ plans), de-staffing continued (but should end soon), and price growth was marginal. Fifty-two percent of manufacturing gross domestic product (GDP) contracted in December, down from 66 percent in November. The share of manufacturing sector GDP registering a composite PMI® calculation at or below 45 percent (a good barometer of overall manufacturing weakness) was 49 percent in December, a 1-percentage point increase compared to the 48 percent reported in November. None of the six largest manufacturing industries expanded in December, down from two in November,” says Fiore.

The seven manufacturing industries reporting growth in December — listed in order — are: Primary Metals; Electrical Equipment, Appliances & Components; Wood Products; Furniture & Related Products; Paper Products; Miscellaneous Manufacturing; and Plastics & Rubber Products. The seven industries reporting contraction in December — in the following order — are: Textile Mills; Fabricated Metal Products; Printing & Related Support Activities; Machinery; Chemical Products; Transportation Equipment; and Nonmetallic Mineral Products.

WHAT RESPONDENTS ARE SAYING

- “Slightly lower due to seasonality and end-of-year destocking.” [Chemical Products]

- “Automotive and powersport volume decreases.” [Transportation Equipment]

- “We are seeing a softening in sales. This is concerning as it’s our peak season.” [Food, Beverage & Tobacco Products]

- “We are constrained by technical labor, despite higher-than-normal backlog.” [Computer & Electronic Products]

- “Significant slowdown in production requirements in the last two months of the year.” [Machinery]

- “Order levels well below forecast projections.” [Fabricated Metal Products]

- “The increase in new orders has our plant at full capacity.” [Electrical Equipment, Appliances & Components]

- “Combo of seasonal factors plus increased demand outlook for 2025.” [Miscellaneous Manufacturing]

- “There is definitely an uptick this month, though not a stable one.” [Primary Metals]

- “The orders have increased slightly due to seasonal restocking.” [Plastics & Rubber Products]

MANUFACTURING AT A GLANCE

December 2024Index

Series

IndexDec

Series

IndexNov

Percentage

Point

Change

Direction

Rate of

ChangeTrend*

(Months)Manufacturing PMI®

49.3

48.4

+0.9

Contracting

Slower

9

New Orders

52.5

50.4

+2.1

Growing

Faster

2

Production

50.3

46.8

+3.5

Growing

From

Contracting1

Employment

45.3

48.1

-2.8

Contracting

Faster

7

Supplier Deliveries

50.1

48.7

+1.4

Slowing

From Faster

1

Inventories

48.4

48.1

+0.3

Contracting

Slower

4

Customers’ Inventories

46.7

48.4

-1.7

Too Low

Faster

3

Prices

52.5

50.3

+2.2

Increasing

Faster

3

Backlog of Orders

45.9

41.8

+4.1

Contracting

Slower

27

New Export Orders

50.0

48.7

+1.3

Unchanged

From

Contracting1

Imports

49.7

47.6

+2.1

Contracting

Slower

7

OVERALL ECONOMY

Growing

Faster

56

Manufacturing Sector

Contracting

Slower

9

Manufacturing ISM® Report On Business® data is seasonally adjusted for the New Orders, Production, Employment and Inventories indexes.

*Number of months moving in current direction.

COMMODITIES REPORTED UP/DOWN IN PRICE AND IN SHORT SUPPLY

Commodities Up in Price

Aluminum (13); Caustic Soda (2); Copper (3); Electronic Components; Labor — Temporary; Methanol; Natural Gas (3); Packaging Materials; Steel — General*; Steel — High Carbon; and Steel-Making Elements*.Commodities Down in Price

Diesel Fuel (2); Plastic Resin (2); Polypropylene Resin; Solvents (2); Steel — General*; Steel — Hot Rolled (2); Steel — Scrap; and Steel-Making Elements*.Commodities in Short Supply

Electrical Components (51); Electronic Components (9); and Labor — Construction Services and Skilled.Note: The number of consecutive months the commodity is listed is indicated after each item.

*Indicates both up and down in price.

DECEMBER 2024 MANUFACTURING INDEX SUMMARIES

Manufacturing PMI®

The U.S. manufacturing sector contracted for the ninth consecutive month in December, as the Manufacturing PMI® registered 49.3 percent, 0.9 percentage point higher compared to the 48.4 percent reported in November. “After breaking a 16-month streak of contraction by expanding in March, the manufacturing sector has contracted for the last nine months. Of the five subindexes that directly factor into the Manufacturing PMI®, three (New Orders, Production and Supplier Deliveries) were in expansion territory, compared to only one in November. The Employment Index remained in contraction, but the New Orders Index moved further into expansion in December. Of the six biggest manufacturing industries, none registered growth,” says Fiore. A reading above 50 percent indicates that the manufacturing sector is generally expanding; below 50 percent indicates that it is generally contracting.A Manufacturing PMI® above 42.5 percent, over a period of time, generally indicates an expansion of the overall economy. Therefore, the December Manufacturing PMI® indicates the overall economy grew for the 56th straight month after last contracting in April 2020. “The past relationship between the Manufacturing PMI® and the overall economy indicates that the December reading (49.3 percent) corresponds to a change of plus-1.9 percent in real gross domestic product (GDP) on an annualized basis,” says Fiore.

THE LAST 12 MONTHS

Month

Manufacturing

PMI®Month

Manufacturing

PMI®Dec 2024

49.3

Jun 2024

48.5

Nov 2024

48.4

May 2024

48.7

Oct 2024

46.5

Apr 2024

49.2

Sep 2024

47.2

Mar 2024

50.3

Aug 2024

47.2

Feb 2024

47.8

Jul 2024

46.8

Jan 2024

49.1

Average for 12 months – 48.3

High – 50.3

Low – 46.5

New Orders

ISM®‘s New Orders Index expanded in December for the second consecutive month after seven months in contraction, registering 52.5 percent, an increase of 2.1 percentage points compared to November’s figure of 50.4 percent. The New Orders Index hasn’t indicated consistent growth since a 24-month streak of expansion ended in May 2022. “Of the six largest manufacturing sectors, two (Food, Beverage & Tobacco Products; and Computer & Electronic Products) reported increased new orders. Panelists noted an improved level of demand performance, with a 1.5-to-1 ratio of positive comments versus those expressing concern about near-term demand, an improvement compared to November,” says Fiore. A New Orders Index above 52.3 percent, over time, is generally consistent with an increase in the Census Bureau’s series on manufacturing orders (in constant 2000 dollars).The six manufacturing industries that reported growth in new orders in December, in order, are: Electrical Equipment, Appliances & Components; Paper Products; Food, Beverage & Tobacco Products; Miscellaneous Manufacturing; Primary Metals; and Computer & Electronic Products. The eight industries reporting a decline in new orders in December — in the following order — are: Textile Mills; Printing & Related Support Activities; Nonmetallic Mineral Products; Wood Products; Transportation Equipment; Fabricated Metal Products; Plastics & Rubber Products; and Machinery.

New Orders

%Higher

%Same

%Lower

Net

Index

Dec 2024

21.0

54.9

24.1

-3.1

52.5

Nov 2024

21.0

54.3

24.7

-3.7

50.4

Oct 2024

20.4

50.6

29.0

-8.6

47.1

Sep 2024

17.6

56.1

26.3

-8.7

46.1

Production

The Production Index emerged into expansion territory in December, registering 50.3 percent, 3.5 percentage points higher than the November reading of 46.8 percent. Prior to this month’s reading, the index was in contraction territory for six consecutive months. The last time the index registered above 50 percent was in May (50.2 percent). Of the six largest manufacturing sectors, only one (Computer & Electronic Products) reported increased production. “Production levels were stable to November’s performance, indicating that re-planning factory floor activity has likely been completed, head counts are likely synchronized with factory demand, and panelists are fully staffed and aligned for 2025,” says Fiore. An index above 52.2 percent, over time, is generally consistent with an increase in the Federal Reserve Board’s Industrial Production figures.The five industries reporting growth in production during the month of December are: Textile Mills; Plastics & Rubber Products; Wood Products; Computer & Electronic Products; and Primary Metals. The six industries reporting a decrease in production in December, in order, are: Printing & Related Support Activities; Fabricated Metal Products; Nonmetallic Mineral Products; Machinery; Chemical Products; and Transportation Equipment. Six industries reported no change in production levels in December as compared to November.

Production

%Higher

%Same

%Lower

Net

Index

Dec 2024

15.3

59.3

25.4

-10.1

50.3

Nov 2024

15.9

63.2

20.9

-5.0

46.8

Oct 2024

16.8

59.3

23.9

-7.1

46.2

Sep 2024

17.6

60.7

21.7

-4.1

49.8

Employment

ISM®‘s Employment Index registered 45.3 percent in December, 2.8 percentage points lower than the November reading of 48.1 percent. “The index contracted for the seventh consecutive month and the 14th out of the last 15 months. Of the six big manufacturing sectors, none expanded employment in December. Respondents’ companies are continuing to reduce head counts through layoffs, attrition and hiring freezes. This action is supported in December by the approximately 1-to-2 ratio of hiring versus staff-reduction comments, compared to a 1-to-1.5 ratio the previous month, meaning more workforce reduction activity is occurring as we close 2025,” says Fiore. An Employment Index above 50.3 percent, over time, is generally consistent with an increase in the Bureau of Labor Statistics (BLS) data on manufacturing employment.Of 18 manufacturing industries, the two industries reporting employment growth in December are: Electrical Equipment, Appliances & Components; and Plastics & Rubber Products. The nine industries reporting a decrease in employment in December, in the following order, are: Textile Mills; Fabricated Metal Products; Machinery; Chemical Products; Furniture & Related Products; Food, Beverage & Tobacco Products; Primary Metals; Transportation Equipment; and Miscellaneous Manufacturing. Six industries reported no change in employment levels in December as compared to November.

Employment

%Higher

%Same

%Lower

Net

Index

Dec 2024

7.0

75.3

17.7

-10.7

45.3

Nov 2024

14.2

65.3

20.5

-6.3

48.1

Oct 2024

9.0

70.6

20.4

-11.4

44.4

Sep 2024

8.0

69.3

22.7

-14.7

43.9

Supplier Deliveries†

Delivery performance of suppliers to manufacturing organizations was marginally slower in December, with the Supplier Deliveries Index registering 50.1 percent, a 1.4-percentage point increase compared to the reading of 48.7 percent reported in November. This expansion follows a contraction in November preceded by four consecutive months of slower deliveries, with four straight months of faster deliveries before that. After a reading of 52.4 percent in September 2022, the index went into contraction territory the following month and remained there for 20 out of 21 months (with February 2024 as the exception). Of the six big industries, two (Computer & Electronic Products; and Food, Beverage & Tobacco Products) reported slower supplier deliveries in December. “Supplier deliveries moved into ‘slower’ territory as supplier delivery performance continues to meet the expectations of panelists’ customers,” says Fiore. A reading below 50 percent indicates faster deliveries, while a reading above 50 percent indicates slower deliveries.The six manufacturing industries reporting slower supplier deliveries in December — listed in order — are: Furniture & Related Products; Nonmetallic Mineral Products; Primary Metals; Computer & Electronic Products; Electrical Equipment, Appliances & Components; and Food, Beverage & Tobacco Products. The three industries reporting faster supplier deliveries in December are: Fabricated Metal Products; Chemical Products; and Machinery. Eight industries reported no change in supplier deliveries in December as compared to November.

Supplier Deliveries

%Slower

%Same

%Faster

Net

Index

Dec 2024

6.4

87.4

6.2

+0.2

50.1

Nov 2024

5.7

86.0

8.3

-2.6

48.7

Oct 2024

11.9

80.1

8.0

+3.9

52.0

Sep 2024

10.4

83.6

6.0

+4.4

52.2

Inventories

The Inventories Index registered 48.4 percent in December, up 0.3 percentage point compared to the reading of 48.1 percent reported in November. The last time the Inventories Index registered above 50 percent was in August, when it registered 50.3 percent. “Manufacturing inventories continue to contract, though rates have slowed in in the last two months as panelists continue to manage working capital. This month’s index reading indicating a slowing rate of contraction suggests that companies are willing to invest more for the future, to (1) better perform to their customers’ delivery demands or (2) advance material deliveries to avoid potential tariffs, or a combination of both. Of the six big industries, none reported expanding manufacturing inventories in December,” says Fiore. An Inventories Index greater than 44.4 percent, over time, is generally consistent with expansion in the Bureau of Economic Analysis (BEA) figures on overall manufacturing inventories (in chained 2000 dollars).Of 18 manufacturing industries, the five industries reporting higher inventories in December are: Primary Metals; Wood Products; Furniture & Related Products; Nonmetallic Mineral Products; and Electrical Equipment, Appliances & Components. The eight industries reporting lower inventories in December — in the following order — are: Textile Mills; Fabricated Metal Products; Computer & Electronic Products; Chemical Products; Plastics & Rubber Products; Food, Beverage & Tobacco Products; Machinery; and Transportation Equipment.

Inventories

%Higher

%Same

%Lower

Net

Index

Dec 2024

14.4

64.8

20.8

-6.4

48.4

Nov 2024

15.5

63.2

21.3

-5.8

48.1

Oct 2024

14.2

59.1

26.7

-12.5

42.6

Sep 2024

11.2

66.5

22.3

-11.1

43.9

Customers’ Inventories†

ISM®‘s Customers’ Inventories Index registered a reading of 46.7 percent in December, down 1.7 percentage points compared to the 48.4 percent reported in November. “Customers’ inventory levels in December have dropped to the high side of ‘too low.’ Panelists are reporting that the amounts of their products in their customers’ inventories suggest a demand level that is positive for future production,” says Fiore.The four industries reporting customers’ inventories as too high in December are: Textile Mills; Wood Products; Plastics & Rubber Products; and Miscellaneous Manufacturing. The 10 industries reporting customers’ inventories as too low in December, in order, are: Food, Beverage & Tobacco Products; Paper Products; Furniture & Related Products; Electrical Equipment, Appliances & Components; Machinery; Primary Metals; Computer & Electronic Products; Fabricated Metal Products; Transportation Equipment; and Chemical Products.

Customers’

Inventories%

Reporting%Too

High%About

Right%Too

LowNet

Index

Dec 2024

78

11.5

70.3

18.2

-6.7

46.7

Nov 2024

77

10.6

75.5

13.9

-3.3

48.4

Oct 2024

80

12.2

69.1

18.7

-6.5

46.8

Sep 2024

76

13.2

73.6

13.2

0.0

50.0

Prices†

The ISM® Prices Index registered 52.5 percent, 2.2 percentage points higher compared to the November reading of 50.3 percent, indicating raw materials prices increased for the third straight month in December after a decrease in September. Of the six largest manufacturing industries, three — Food, Beverage & Tobacco Products; Machinery; and Computer & Electronic Products — reported price increases in December. “The Prices Index indicated increasing prices in December for the third consecutive month, but at weak rates. Aluminum, basic chemicals, copper and natural gas registered increases, offset by steel, plastic resins and diesel fuel moving down in price. Fourteen percent of companies reported higher prices in December, compared to 12 percent in November,” says Fiore. A Prices Index above 52.8 percent, over time, is generally consistent with an increase in the Bureau of Labor Statistics (BLS) Producer Price Index for Intermediate Materials.In December, the seven industries that reported paying increased prices for raw materials, in order, are: Primary Metals; Wood Products; Food, Beverage & Tobacco Products; Miscellaneous Manufacturing; Machinery; Computer & Electronic Products; and Electrical Equipment, Appliances & Components. The three industries report paying decreased prices for raw materials in December are: Plastics & Rubber Products; Chemical Products; and Fabricated Metal Products. Seven industries reported no change in prices in December as compared to November.

Prices

%Higher

%Same

%Lower

Net

Index

Dec 2024

14.4

76.1

9.5

+4.9

52.5

Nov 2024

12.2

76.1

11.7

+0.5

50.3

Oct 2024

19.8

69.9

10.3

+9.5

54.8

Sep 2024

12.9

70.7

16.4

-3.5

48.3

Backlog of Orders†

ISM®‘s Backlog of Orders Index registered 45.9 percent, an increase of 4.1 percentage points compared to the November reading of 41.8 percent, indicating order backlogs contracted for the 27th consecutive month after a 27-month period of expansion. Of the six largest manufacturing industries, two (Food, Beverage & Tobacco Products; and Computer & Electronic Products) reported expanded order backlogs in December. “In December, the index recorded its best performance since April 2024 (45.4 percent), as new orders coupled with stable production levels slowed the rate of declining backlogs,” says Fiore.Of the 18 manufacturing industries, three reported growth in order backlogs in December: Food, Beverage & Tobacco Products; Computer & Electronic Products; and Electrical Equipment, Appliances & Components. The 10 industries reporting lower backlogs in December — in the following order — are: Textile Mills; Primary Metals; Printing & Related Support Activities; Furniture & Related Products; Plastics & Rubber Products; Wood Products; Machinery; Transportation Equipment; Chemical Products; and Miscellaneous Manufacturing.

Backlog of

Orders%

Reporting%Higher

%Same

%Lower

Net

Index

Dec 2024

91

14.9

62.0

23.1

-8.2

45.9

Nov 2024

92

14.5

54.6

30.9

-16.4

41.8

Oct 2024

93

14.1

56.4

29.5

-15.4

42.3

Sep 2024

92

14.5

59.1

26.4

-11.9

44.1

New Export Orders†

ISM®‘s New Export Orders Index registered an “unchanged” reading of 50 percent in December, up 1.3 percentage points from November’s reading of 48.7 percent. “The New Export Orders Index reading indicates that export orders were ‘unchanged’ from last month, following six straight months of contraction. New export orders stabilized this month as international trading partners are showing signs of demand recovery as we enter 2025,” says Fiore.The four industries reporting growth in new export orders in December are: Plastics & Rubber Products; Food, Beverage & Tobacco Products; Computer & Electronic Products; and Miscellaneous Manufacturing. The four industries reporting a decrease in new export orders in December are: Primary Metals; Transportation Equipment; Machinery; and Chemical Products. Eight industries reported no change in exports in December.

New Export

Orders%

Reporting%Higher

%Same

%Lower

Net

Index

Dec 2024

74

10.9

78.2

10.9

0.0

50.0

Nov 2024

75

10.6

76.1

13.3

-2.7

48.7

Oct 2024

74

7.7

75.6

16.7

-9.0

45.5

Sep 2024

73

7.2

76.1

16.7

-9.5

45.3

Imports†

ISM®‘s Imports Index continued to indicate cooling in December; the reading of 49.7 percent is 2.1 percentage points higher compared to the reading of 47.6 reported in November. “Imports contracted for the seventh month in a row after five consecutive months of expansion, preceded by 14 consecutive months of contraction. Imports moved closer to growth as inventory constraints weaken and panelists act to better absorb any potential tariff impact in the future,” says Fiore.The seven industries reporting an increase in import volumes in December, in order, are: Wood Products; Plastics & Rubber Products; Furniture & Related Products; Food, Beverage & Tobacco Products; Machinery; Electrical Equipment, Appliances & Components; and Computer & Electronic Products. The five industries that reported lower volumes of imports in December are: Paper Products; Printing & Related Support Activities; Primary Metals; Transportation Equipment; and Fabricated Metal Products.

Imports

%

Reporting%Higher

%Same

%Lower

Net

Index

Dec 2024

85

12.8

73.8

13.4

-0.6

49.7

Nov 2024

83

10.2

74.8

15.0

-4.8

47.6

Oct 2024

84

11.7

73.1

15.2

-3.5

48.3

Sep 2024

82

10.2

76.2

13.6

-3.4

48.3

†The Supplier Deliveries, Customers’ Inventories, Prices, Backlog of Orders, New Export Orders, and Imports indexes do not meet the accepted criteria for seasonal adjustments.

Buying Policy

The average commitment lead time for Capital Expenditures in December was 175 days, an increase of five days compared to November. Average lead time in December for Production Materials was 81 days, an increase of two days compared to November. Average lead time for Maintenance, Repair and Operating (MRO) Supplies was 46 days, an increase of two days compared to November.Percent Reporting

Capital

ExpendituresHand-to-

Mouth30 Days

60 Days

90 Days

6 Months

1 Year+

Average

DaysDec 2024

14

5

8

15

30

28

175

Nov 2024

16

4

9

15

29

27

170

Oct 2024

16

5

12

12

28

27

168

Sep 2024

16

3

10

13

30

28

174

Percent Reporting

Production

MaterialsHand-to-

Mouth30 Days

60 Days

90 Days

6 Months

1 Year+

Average

DaysDec 2024

7

25

28

27

8

5

81

Nov 2024

8

24

28

27

9

4

79

Oct 2024

9

25

26

26

9

5

81

Sep 2024

7

26

28

27

7

5

80

Percent Reporting

MRO Supplies

Hand-to-

Mouth30 Days

60 Days

90 Days

6 Months

1 Year+

Average

DaysDec 2024

30

35

16

13

5

1

46

Nov 2024

30

34

17

13

6

0

44

Oct 2024

30

34

18

12

5

1

46

Sep 2024

27

37

19

11

5

1

46

About This Report

DO NOT CONFUSE THIS NATIONAL REPORT with the various regional purchasing reports released across the country. The national report’s information reflects the entire U.S., while the regional reports contain primarily regional data from their local vicinities. Also, the information in the regional reports is not used in calculating the results of the national report. The information compiled in this report is for the month of December 2024.The data presented herein is obtained from a survey of manufacturing supply executives based on information they have collected within their respective organizations. ISM® makes no representation, other than that stated within this release, regarding the individual company data collection procedures. The data should be compared to all other economic data sources when used in decision-making.

Data and Method of Presentation

The Manufacturing ISM® Report On Business® is based on data compiled from purchasing and supply executives nationwide. The composition of the Manufacturing Business Survey Committee is stratified according to the North American Industry Classification System (NAICS) and each of the following NAICS-based industries’ contribution to gross domestic product (GDP): Food, Beverage & Tobacco Products; Textile Mills; Apparel, Leather & Allied Products; Wood Products; Paper Products; Printing & Related Support Activities; Petroleum & Coal Products; Chemical Products; Plastics & Rubber Products; Nonmetallic Mineral Products; Primary Metals; Fabricated Metal Products; Machinery; Computer & Electronic Products; Electrical Equipment, Appliances & Components; Transportation Equipment; Furniture & Related Products; and Miscellaneous Manufacturing (products such as medical equipment and supplies, jewelry, sporting goods, toys and office supplies). The data is weighted based on each industry’s contribution to GDP. According to BEA estimates (the average of the fourth quarter 2022 GDP estimate and the GDP estimates for first, second, and third quarter 2023, as released on December 21, 2023), the six largest manufacturing industries are: Chemical Products; Transportation Equipment; Food, Beverage & Tobacco Products; Computer & Electronic Products; Machinery; and Fabricated Metal Products.Survey responses reflect the change, if any, in the current month compared to the previous month. For nine indicators (New Orders, Backlog of Orders, New Export Orders, Imports, Production, Supplier Deliveries, Inventories, Employment, and Prices), this report shows the percentage reporting each response, the net difference between the number of responses in the positive economic direction (higher, better and slower for Supplier Deliveries) and the negative economic direction (lower, worse and faster for Supplier Deliveries), and the diffusion index. For Customers’ Inventories, respondents report their assessment of their customers’ stock levels of respondent companies’ products this month (rather than last month): too high, about right, and too low. Responses are raw data and are never changed. The diffusion index includes the percent of positive responses plus one-half of those responding the same (considered positive).

The resulting single index number for those meeting the criteria for seasonal adjustments (Manufacturing PMI®, New Orders, Production, Employment and Inventories) is then seasonally adjusted to allow for the effects of repetitive intra-year variations resulting primarily from normal differences in weather conditions, various institutional arrangements, and differences attributable to non-moveable holidays. All seasonal adjustment factors are subject annually to relatively minor changes when conditions warrant them. The Manufacturing PMI® is a composite index based on the diffusion indexes of five of the indexes with equal weights: New Orders (seasonally adjusted), Production (seasonally adjusted), Employment (seasonally adjusted), Supplier Deliveries, and Inventories (seasonally adjusted).

Diffusion indexes have the properties of leading indicators and are convenient summary measures showing the prevailing direction of change and the scope of change. A Manufacturing PMI® reading above 50 percent indicates that the manufacturing economy is generally expanding; below 50 percent indicates that it is generally declining. A Manufacturing PMI® above 42.5 percent, over a period of time, indicates that the overall economy, or gross domestic product (GDP), is generally expanding; below 42.5 percent, it is generally declining. The distance from 50 percent or 42.5 percent is indicative of the extent of the expansion or decline. With some of the indicators within this report, ISM® has indicated the departure point between expansion and decline of comparable government series, as determined by regression analysis. For the Customers’ Inventories Index, numerically, a reading: above 50 percent is “too high,” equal to 50 percent is “about right,” and below 50 percent is “too low.” However, in practice and in the context of other data, customers’ inventories may be considered to be “about right” if the diffusion index is between 52 percent (the high side of about right) and 48 percent (the low side of about right).

The Manufacturing ISM® Report On Business® survey is sent out to Manufacturing Business Survey Committee respondents the first part of each month. Respondents are asked to report on information for the current month for U.S. operations only. ISM® receives survey responses throughout most of any given month, with the majority of respondents generally waiting until late in the month to submit responses to give the most accurate picture of current business activity. ISM® then compiles the report for release on the first business day of the following month.

The industries reporting growth, as indicated in the Manufacturing ISM® Report On Business® monthly report, are listed in the order of most growth to least growth. For the industries reporting contraction or decreases, those are listed in the order of the highest level of contraction/decrease to the least level of contraction/decrease.

Responses to Buying Policy reflect the percent reporting the current month’s lead time, the approximate weighted number of days ahead for which commitments are made for Capital Expenditures; Production Materials; and Maintenance, Repair and Operating (MRO) Supplies, expressed as hand-to-mouth (five days), 30 days, 60 days, 90 days, six months (180 days), a year or more (360 days), and the weighted average number of days. These responses are raw data, never revised, and not seasonally adjusted.

ISM ROB Content

The Institute for Supply Management® (“ISM”) Report On Business® (both Manufacturing and Non-Manufacturing) (“ISM ROB”) contains information, text, files, images, video, sounds, musical works, works of authorship, applications, and any other materials or content (collectively, “Content”) of ISM (“ISM ROB Content”). ISM ROB Content is protected by copyright, trademark, trade secret, and other laws, and as between you and ISM, ISM owns and retains all rights in the ISM ROB Content. ISM hereby grants you a limited, revocable, nonsublicensable license to access and display on your individual device the ISM ROB Content (excluding any software code) solely for your personal, non-commercial use. The ISM ROB Content shall also contain Content of users and other ISM licensors. Except as provided herein or as explicitly allowed in writing by ISM, you shall not copy, download, stream, capture, reproduce, duplicate, archive, upload, modify, translate, publish, broadcast, transmit, retransmit, distribute, perform, display, sell, or otherwise use any ISM ROB Content.Except as explicitly and expressly permitted by ISM, you are strictly prohibited from creating works or materials (including but not limited to tables, charts, data streams, time-series variables, fonts, icons, link buttons, wallpaper, desktop themes, online postcards, montages, mashups and similar videos, greeting cards, and unlicensed merchandise) that derive from or are based on the ISM ROB Content. This prohibition applies regardless of whether the derivative works or materials are sold, bartered, or given away. You shall not either directly or through the use of any device, software, internet site, web-based service, or other means remove, alter, bypass, avoid, interfere with, or circumvent any copyright, trademark, or other proprietary notices marked on the Content or any digital rights management mechanism, device, or other content protection or access control measure associated with the Content including geo-filtering mechanisms. Without prior written authorization from ISM, you shall not build a business utilizing the Content, whether or not for profit.

You shall not create, recreate, distribute, incorporate in other work, or advertise an index of any portion of the Content unless you receive prior written authorization from ISM. Requests for permission to reproduce or distribute ISM ROB Content can be made by contacting in writing at: ISM Research, Institute for Supply Management, 309 West Elliot Road, Suite 113, Tempe, Arizona 85284-1556, or by emailing [email protected]. Subject: Content Request.

ISM shall not have any liability, duty, or obligation for or relating to the ISM ROB Content or other information contained herein, any errors, inaccuracies, omissions or delays in providing any ISM ROB Content, or for any actions taken in reliance thereon. In no event shall ISM be liable for any special, incidental, or consequential damages arising out of the use of the ISM ROB. Report On Business®, PMI®, Manufacturing PMI®, Services PMI®, Hospital PMI®, and NMI® are registered trademarks of Institute for Supply Management®. Institute for Supply Management® and ISM® are registered trademarks of Institute for Supply Management, Inc.

About Institute for Supply Management® (ISM®)

Institute for Supply Management® (ISM®) is the first and leading not-for-profit professional supply management organization worldwide. Its community of more than 50,000 in more than 100 countries manages about US$1 trillion in corporate and government supply chain procurement annually. Founded in 1915 by practitioners, ISM is committed to advancing the practice of supply management to drive value and competitive advantage for its members, contributing to a prosperous and sustainable world. ISM empowers and leads the profession through the ISM® Report On Business®, its highly regarded certification and training programs, corporate services, events and assessments. The ISM® Report On Business®, Manufacturing, Services, and Hospital, are three of the most reliable economic indicators available, providing guidance to supply management professionals, economists, analysts, and government and business leaders. For more information, please visit: www.ismworld.org.The full text version of the Manufacturing ISM® Report On Business® is posted on ISM®‘s website at www.ismrob.org on the first business day* of every month after 10:00 a.m. ET. The one exception is in January when the report is released on the second business day of the month.

The next Manufacturing ISM® Report On Business® featuring January 2025 data will be released at 10:00 a.m. ET on Monday, February 3, 2025.

*Unless the New York Stock Exchange is closed.

Contact:

Kristina Cahill

Report On Business® Analyst

ISM®, ROB/Research Manager

Tempe, Arizona

+1 480.455.5910

Email: [email protected]

SOURCE Institute for Supply Management

The latest Manufacturing PMI® report for December 2024 has been released, showing a reading of 49.3%. This indicates a slight contraction in the manufacturing sector, as any reading below 50% suggests a decline in activity.The December 2024 Manufacturing ISM® Report On Business® provides valuable insights into the current state of the manufacturing industry, highlighting trends and challenges facing businesses in this sector. It is important for manufacturers to stay informed about these reports in order to make informed decisions and adapt to changing market conditions.

Stay tuned for more updates on the manufacturing sector and how it may impact your business in the coming months.

Tags:

Manufacturing PMI, Manufacturing ISM Report, December 2024, Business Report, Manufacturing Trends, Economic Indicators, Manufacturing Industry Insights, PMI Analysis, ISM Report Summary

#Manufacturing #PMI #December #Manufacturing #ISM #Report #Business

US manufacturing PMI rises to nine-month high in December

WASHINGTON (Reuters) – U.S. manufacturing moved closer to recovery in December, with production rebounding and new orders rising further, though factories faced higher prices for inputs as the year ended.

The Institute for Supply Management (ISM) said on Friday that its manufacturing PMI increased to 49.3 last month, the highest reading since March, from 48.4 in November.

A PMI reading below 50 indicates contraction in the manufacturing sector, which accounts for 10.3% of the economy. December was the ninth consecutive month that the PMI remained below the 50 threshold. Economists polled by Reuters had forecast the PMI unchanged at 48.4.

Manufacturing was battered by the Federal Reserve’s aggressive monetary policy tightening in 2022 and 2023 to tame inflation. But sentiment surveys, including the PMI, have exaggerated the magnitude of the decline in factory production.

Government data last month showed manufacturing growing at a 3.2% annualized rate in the third quarter and contributing to the economy’s 3.1% expansion pace during that period.

The U.S. central bank is cutting interest rates, lowering its benchmark overnight interest rate by 25 basis points to the 4.25%-4.50% range last month. It was the third consecutive rate cut since the Fed started its easing cycle in September.

The Fed’s policy rate was hiked by 5.25 percentage points in 2022 and 2023.

A pledge by President-elect Donald Trump’s incoming administration to cut taxes could provide a boost to manufacturing. But other policy promises, including higher tariffs on imported goods, could raise prices of raw materials.

The Fed has projected two rate cuts this year, fewer than the four it had forecast in September because of the economy’s resilience and uncertainty over the impact of the Trump administration’s policies.

The ISM survey’s forward-looking new orders sub-index increased to 52.5 from 50.4 in November, which marked the first expansion since March. Production at factories rebounded after contracting for months.

Its measure of prices paid by manufacturers rose to 52.5 from 50.3 in November. Its gauge of imports climbed to 49.7 from 47.6 in the prior month. Manufacturers could be bringing in more foreign goods in anticipation of higher tariffs. Trump has vowed to impose a 25% tariff on all products from Mexico and Canada, and an additional 10% tariff on goods from China.

The survey’s gauge of supplier deliveries increased to 50.1 from 48.7 in November. A reading above 50 indicates slower deliveries. Factory employment contracted further, with the survey’s manufacturing jobs index falling to 45.3 from 48.1 in November.

The US manufacturing Purchasing Managers’ Index (PMI) reached a nine-month high in December, signaling a strong end to the year for the sector.According to the latest data from the Institute for Supply Management (ISM), the PMI rose to 58.7 in December, up from 56.9 in November. This marks the highest reading since March and indicates a robust expansion in manufacturing activity.

The increase in the PMI was driven by strong growth in new orders, production, and employment. Manufacturers also reported higher inventories and improved supplier deliveries, suggesting a healthy outlook for the sector.

This positive momentum bodes well for the US economy as a whole, as manufacturing plays a key role in driving overall economic growth. With businesses ramping up production and hiring more workers, the sector is poised for continued expansion in the coming months.

Overall, the rise in the US manufacturing PMI in December is a promising sign for the economy and underscores the resilience of the sector in the face of ongoing challenges.

Tags:

- US manufacturing

- PMI

- December

- Manufacturing industry

- Economic update

- US economy

- Business news

- Manufacturing data

- Industry growth

- Economic indicators

#manufacturing #PMI #rises #ninemonth #high #December

US manufacturing PMI rises to nine-month high in December

WASHINGTON (Reuters) – U.S. manufacturing moved closer to recovery in December, with production rebounding and new orders rising further, though factories faced higher prices for inputs as the year ended.

The Institute for Supply Management (ISM) said on Friday that its manufacturing PMI increased to 49.3 last month, the highest reading since March, from 48.4 in November.

A PMI reading below 50 indicates contraction in the manufacturing sector, which accounts for 10.3% of the economy. December was the ninth consecutive month that the PMI remained below the 50 threshold. Economists polled by Reuters had forecast the PMI unchanged at 48.4.

Trusted news and daily delights, right in your inbox

See for yourself — The Yodel is the go-to source for daily news, entertainment and feel-good stories.

Manufacturing was battered by the Federal Reserve’s aggressive monetary policy tightening in 2022 and 2023 to tame inflation. But sentiment surveys, including the PMI, have exaggerated the magnitude of the decline in factory production.

Government data last month showed manufacturing growing at a 3.2% annualized rate in the third quarter and contributing to the economy’s 3.1% expansion pace during that period.

The U.S. central bank is cutting interest rates, lowering its benchmark overnight interest rate by 25 basis points to the 4.25%-4.50% range last month. It was the third consecutive rate cut since the Fed started its easing cycle in September.

The Fed’s policy rate was hiked by 5.25 percentage points in 2022 and 2023.

A pledge by President-elect Donald Trump’s incoming administration to cut taxes could provide a boost to manufacturing. But other policy promises, including higher tariffs on imported goods, could raise prices of raw materials.

The Fed has projected two rate cuts this year, fewer than the four it had forecast in September because of the economy’s resilience and uncertainty over the impact of the Trump administration’s policies.

The ISM survey’s forward-looking new orders sub-index increased to 52.5 from 50.4 in November, which marked the first expansion since March. Production at factories rebounded after contracting for months.

Its measure of prices paid by manufacturers rose to 52.5 from 50.3 in November. Its gauge of imports climbed to 49.7 from 47.6 in the prior month. Manufacturers could be bringing in more foreign goods in anticipation of higher tariffs. Trump has vowed to impose a 25% tariff on all products from Mexico and Canada, and an additional 10% tariff on goods from China.

The survey’s gauge of supplier deliveries increased to 50.1 from 48.7 in November. A reading above 50 indicates slower deliveries. Factory employment contracted further, with the survey’s manufacturing jobs index falling to 45.3 from 48.1 in November.

This measure has not been a reliable predictor of manufacturing payrolls in the government’s closely watched employment report.

(Reporting by Lucia Mutikani; Editing by Chizu Nomiyama)

The US manufacturing sector ended 2021 on a strong note, with the Purchasing Managers’ Index (PMI) rising to a nine-month high in December. This is a positive sign for the economy, as the PMI is a key indicator of manufacturing activity.According to the latest data from the Institute for Supply Management (ISM), the PMI rose to 59.7 in December, up from 58.1 in November. This marks the highest reading since March and indicates that the manufacturing sector continued to expand at a solid pace.

Several factors contributed to the uptick in the PMI, including strong demand for goods, increased production levels, and improving business conditions. Manufacturers also reported higher levels of new orders, employment, and exports, signaling a broad-based recovery in the sector.

The rise in the PMI bodes well for the overall economy, as a strong manufacturing sector can drive growth in other industries and support job creation. It also suggests that businesses are optimistic about the outlook for 2022, despite ongoing challenges such as supply chain disruptions and inflation.

Overall, the December PMI data is a positive sign for the US economy and provides a strong foundation for growth in the new year.

Tags:

US manufacturing, PMI, nine-month high, December, manufacturing industry, economic indicators, US economy, manufacturing sector, PMI data, growth trends

#manufacturing #PMI #rises #ninemonth #high #December

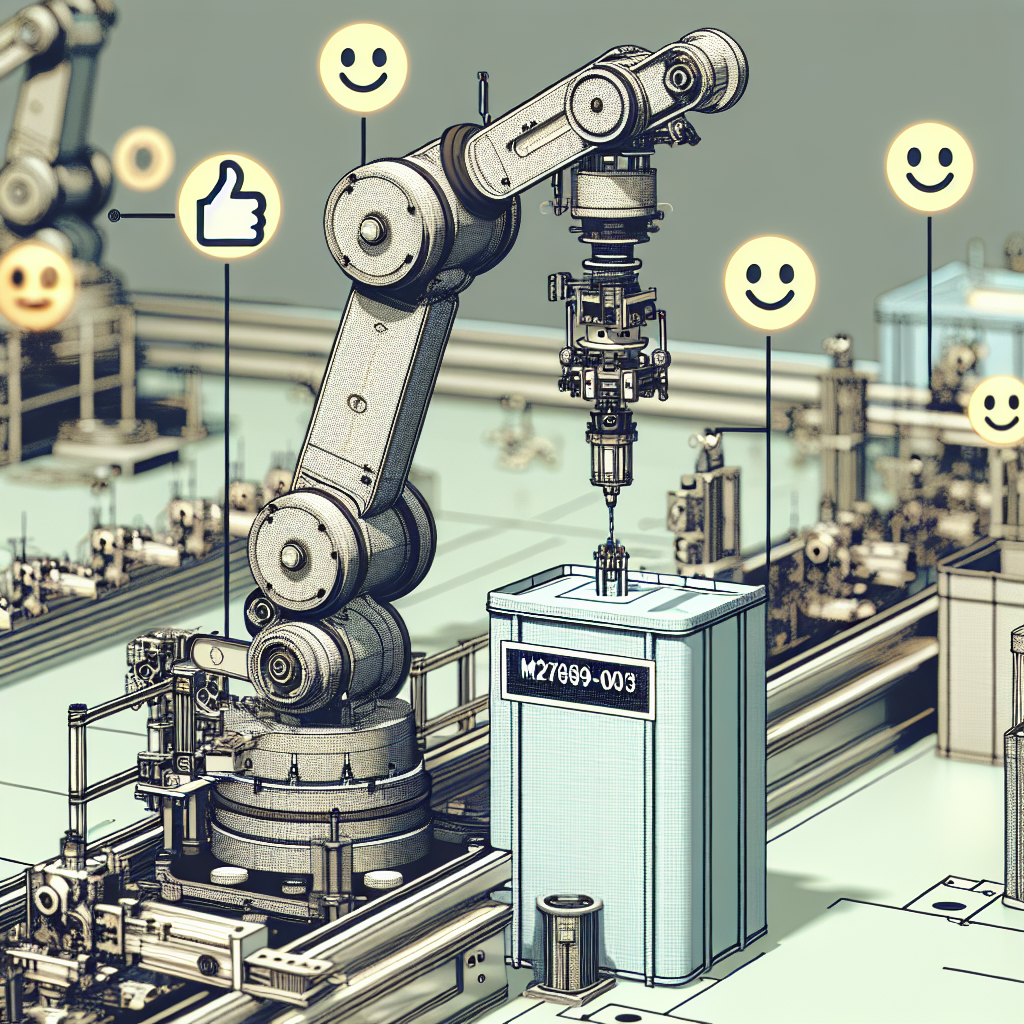

Exploring the Benefits of Using m27699-003 in Manufacturing Processes

In today’s fast-paced manufacturing industry, companies are constantly looking for ways to increase efficiency and productivity. One tool that has been gaining popularity in recent years is the use of m27699-003 in manufacturing processes. This innovative technology offers a wide range of benefits that can help companies streamline their operations and improve overall performance.One of the key benefits of using m27699-003 in manufacturing processes is its ability to improve accuracy and consistency. This technology uses advanced software algorithms to analyze data and make real-time adjustments to production processes. This means that companies can reduce the risk of errors and ensure that each product meets the highest quality standards.

Another advantage of using m27699-003 in manufacturing processes is its ability to increase production speed. By automating certain tasks and processes, companies can significantly reduce the time it takes to manufacture products. This not only allows companies to meet customer demands more quickly, but it also helps them stay ahead of the competition in a rapidly changing market.

In addition to improving accuracy and speed, m27699-003 can also help companies reduce costs. By optimizing production processes and minimizing waste, companies can save money on materials and labor. This can have a significant impact on the bottom line and help companies improve their overall profitability.

Furthermore, m27699-003 can also enhance worker safety in manufacturing processes. By automating certain tasks that are repetitive or dangerous, companies can reduce the risk of accidents and injuries. This not only protects employees, but it also helps companies avoid costly workplace incidents.

Overall, the benefits of using m27699-003 in manufacturing processes are clear. This technology offers companies a way to improve accuracy, speed, cost-effectiveness, and worker safety. By incorporating m27699-003 into their operations, companies can stay competitive in today’s fast-paced manufacturing industry and continue to meet the demands of their customers.

#Exploring #Benefits #m27699003 #Manufacturing #Processes,m27699-003