Price: $138.95 – $94.49

(as of Nov 25,2024 01:54:43 UTC – Details)

From the brand

IEEE, the world’s largest technical professional organization, partners with Wiley to bring to you high-quality books and reference works in electrical engineering and computer science.

Written by leading experts, the books are authoritative and cutting-edge and cover in-demand topics in these important areas of research.

Learn More

Learn More

Publisher : Wiley-IEEE Press; 1st edition (May 22, 2006)

Language : English

Hardcover : 488 pages

ISBN-10 : 0471784060

ISBN-13 : 978-0471784067

Item Weight : 2.31 pounds

Dimensions : 6.4 x 1.18 x 9.51 inches

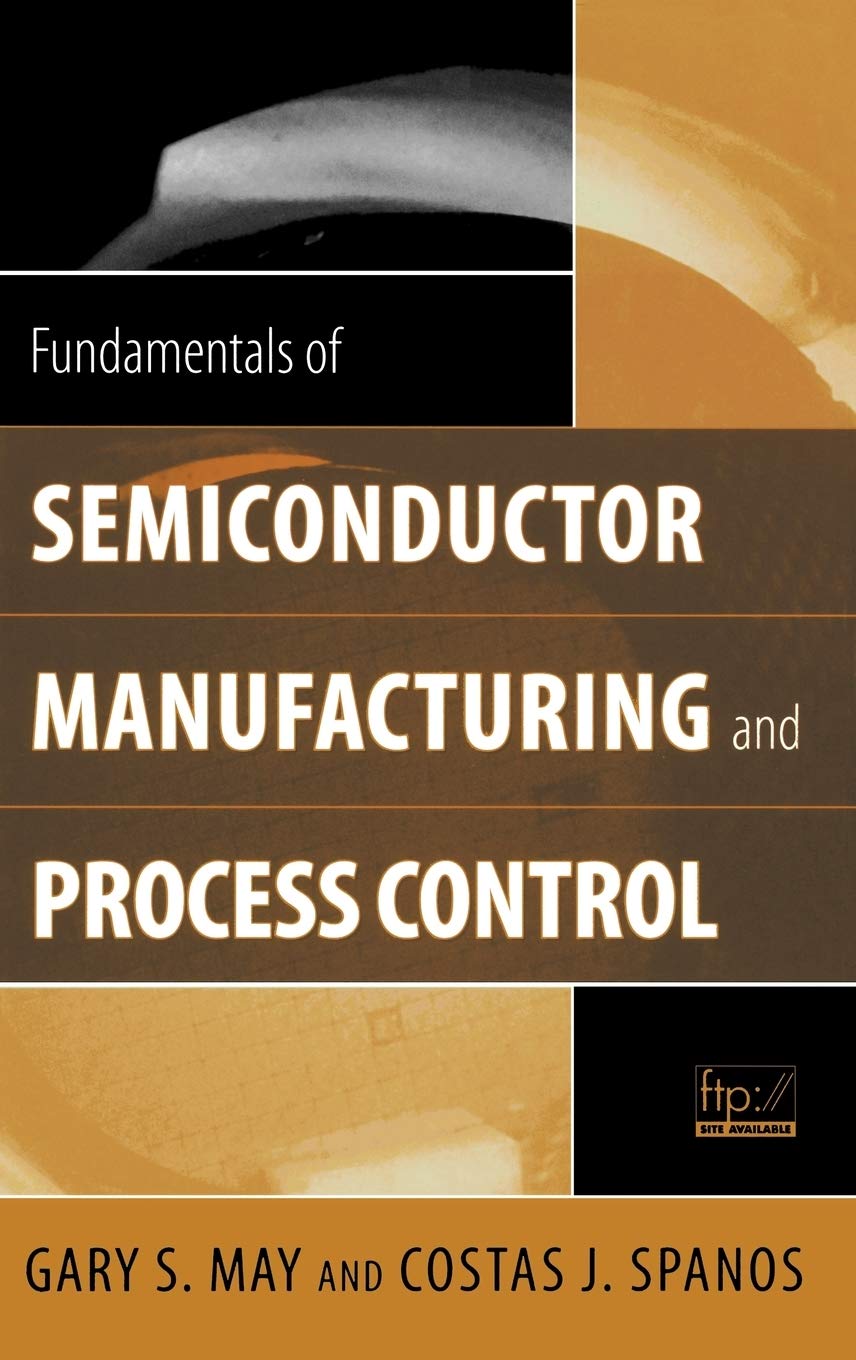

Fundamentals of Semiconductor Manufacturing and Process Control

Semiconductor manufacturing is a complex process that involves the fabrication of integrated circuits (ICs) on silicon wafers. This process requires precise control and monitoring of various parameters to ensure the production of high-quality semiconductor devices. Process control plays a crucial role in semiconductor manufacturing, as it helps to optimize production efficiency, reduce defects, and improve overall product quality.

The semiconductor manufacturing process consists of several key steps, including wafer cleaning, photolithography, etching, doping, and packaging. Each of these steps requires careful control of temperature, pressure, chemical concentrations, and other process parameters to ensure that the final product meets the required specifications.

Process control in semiconductor manufacturing involves the use of advanced measurement and monitoring techniques, such as metrology tools, in-line inspection systems, and statistical process control (SPC) software. These tools help to identify and correct process variations in real-time, ensuring consistent and reliable production of semiconductor devices.

In addition to process control, semiconductor manufacturing also relies on strict quality control measures to ensure that the final product meets the required standards. This includes the use of cleanroom environments, rigorous testing procedures, and adherence to industry regulations and standards.

Overall, semiconductor manufacturing and process control are essential components of the electronics industry, driving innovation and technological advancement. By understanding the fundamentals of semiconductor manufacturing and implementing effective process control measures, manufacturers can produce high-quality semiconductor devices that power a wide range of electronic devices and systems.

#Fundamentals #Semiconductor #Manufacturing #Process #Control