Proactive maintenance is a vital strategy for preventing costly equipment breakdowns in industrial and commercial settings. By implementing a proactive maintenance program, businesses can avoid unexpected downtime, reduce repair costs, and extend the lifespan of their equipment.

Unlike reactive maintenance, which involves waiting for equipment to fail before taking action, proactive maintenance involves regularly inspecting, servicing, and repairing equipment to prevent breakdowns before they occur. This proactive approach can help businesses identify and address potential issues early on, reducing the likelihood of costly repairs and unplanned downtime.

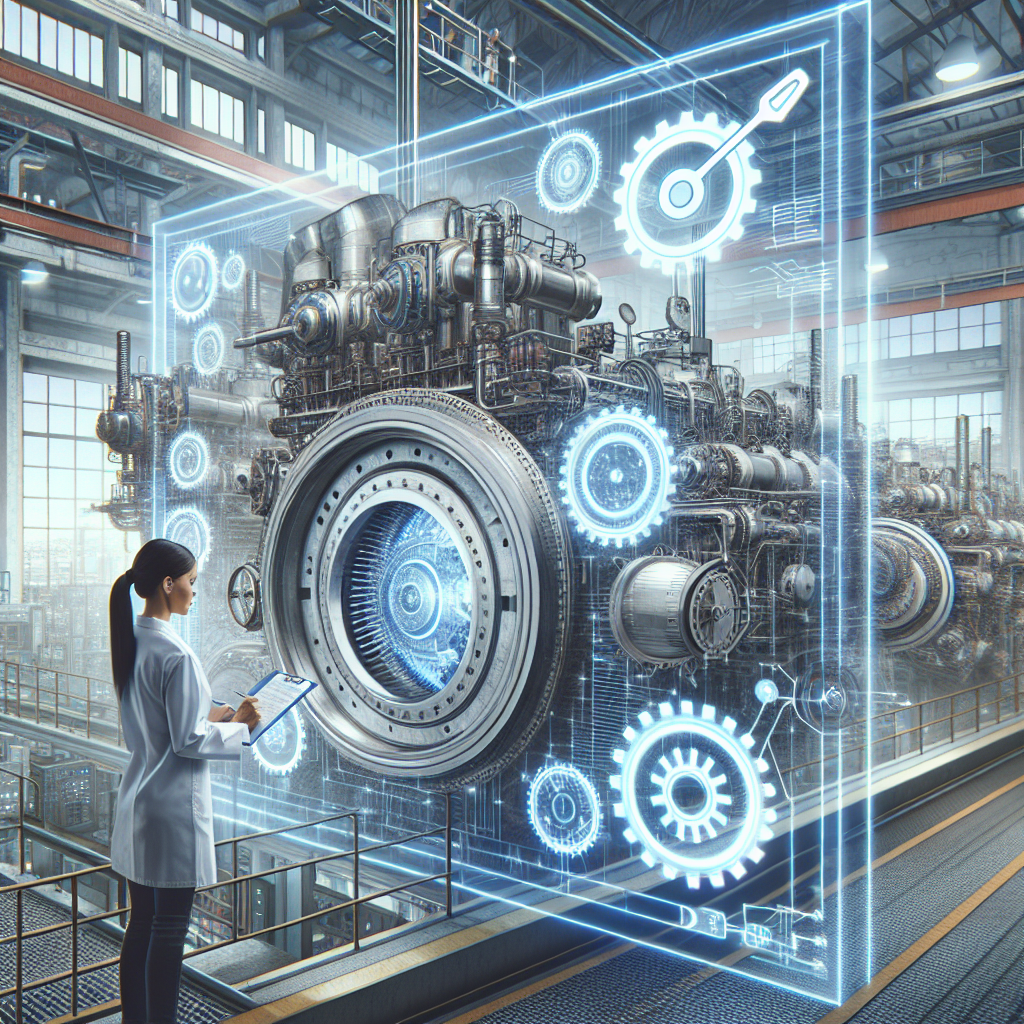

One of the key benefits of proactive maintenance is that it allows businesses to schedule maintenance tasks at convenient times, rather than being forced to address issues in the middle of a busy production schedule. By performing regular inspections and maintenance, businesses can identify and address small issues before they escalate into larger problems that require extensive repairs.

Proactive maintenance also helps businesses save money in the long run by reducing the need for emergency repairs and replacements. By keeping equipment in good working condition, businesses can extend the lifespan of their assets and avoid the high costs associated with unexpected breakdowns.

In addition to saving money, proactive maintenance can also improve the overall efficiency and productivity of a business. By ensuring that equipment is well-maintained and operating at peak performance, businesses can minimize downtime and maximize output, leading to increased profitability and customer satisfaction.

Overall, proactive maintenance is the smart choice for businesses looking to prevent costly equipment breakdowns and improve the reliability and performance of their equipment. By implementing a proactive maintenance program, businesses can save money, increase efficiency, and avoid the headaches associated with unexpected equipment failures. Investing in proactive maintenance is a wise decision that can pay off in the form of reduced costs, increased productivity, and improved customer satisfaction.