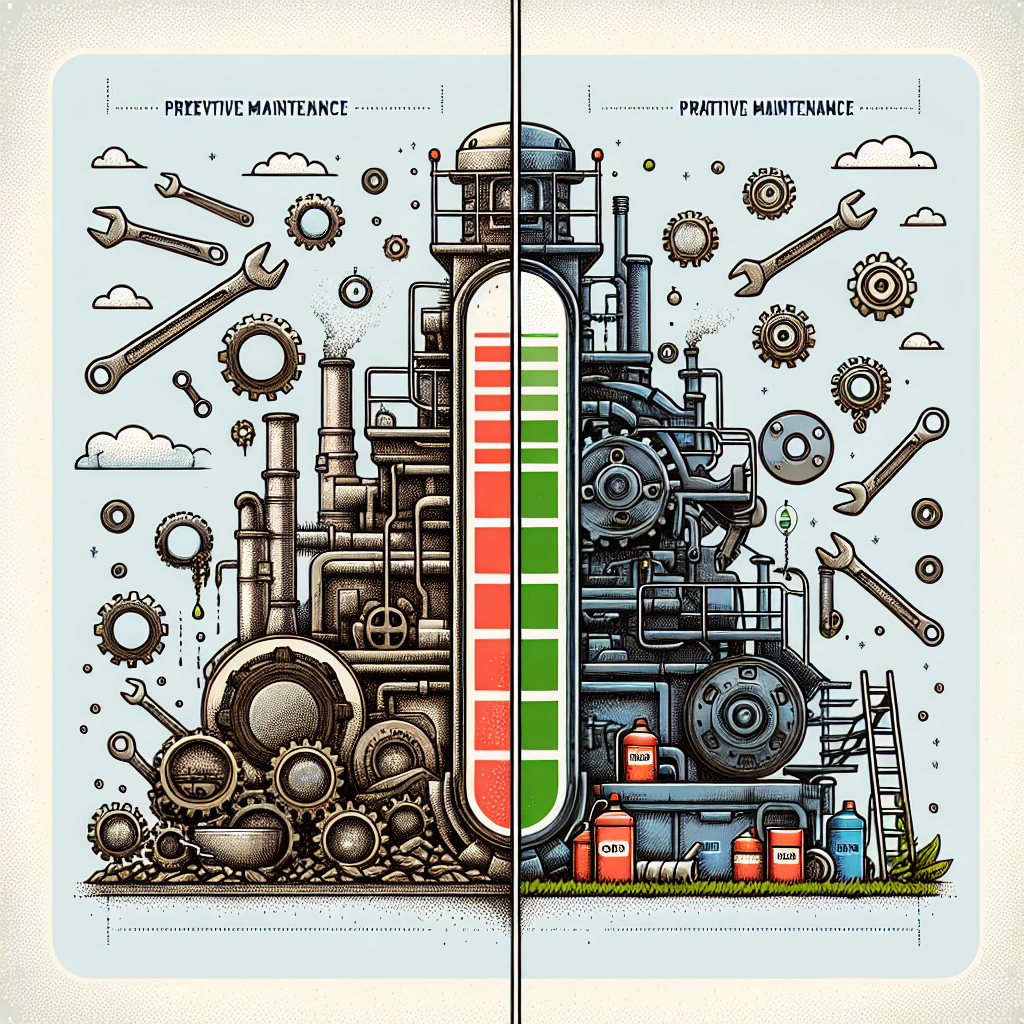

Preventive vs Proactive Maintenance: Which is Right for Your Business?

Maintenance is an essential aspect of running any business, as it ensures that all equipment and machinery are in good working order and can operate efficiently. When it comes to maintenance strategies, two common approaches are preventive maintenance and proactive maintenance. While both strategies aim to prevent breakdowns and ensure the smooth operation of equipment, they differ in their approach and implementation. So, which maintenance strategy is right for your business?

Preventive maintenance is a strategy that involves performing regular maintenance tasks on equipment at scheduled intervals. These tasks are typically based on manufacturer recommendations or industry best practices. The goal of preventive maintenance is to prevent unexpected breakdowns and extend the lifespan of equipment by addressing potential issues before they become major problems. This approach is often seen as a cost-effective way to maintain equipment and reduce downtime.

On the other hand, proactive maintenance takes a more predictive approach to maintenance. Instead of relying on scheduled intervals, proactive maintenance uses data and analytics to identify potential issues before they occur. By monitoring equipment performance and analyzing trends, businesses can anticipate when maintenance is needed and take action proactively. This approach is often seen as more efficient and can help businesses minimize downtime and maximize equipment efficiency.

So, which maintenance strategy is right for your business? The answer depends on several factors, including the type of equipment you have, your budget, and your business goals. Preventive maintenance may be a good option for businesses with a large fleet of equipment that require regular maintenance. It can help businesses stay on top of maintenance tasks and prevent unexpected breakdowns. However, proactive maintenance may be more suitable for businesses that rely heavily on their equipment and cannot afford any downtime. By taking a proactive approach to maintenance, businesses can identify and address potential issues before they impact operations.

Ultimately, the right maintenance strategy for your business will depend on your specific needs and goals. It may be beneficial to consult with maintenance experts or industry professionals to determine the best approach for your business. Whether you choose preventive maintenance or proactive maintenance, the important thing is to prioritize maintenance and ensure that your equipment is well-maintained to keep your business running smoothly.