Your cart is currently empty!

Tag: Proactive Maintenance

How to Implement a Successful Proactive Maintenance Program

Implementing a successful proactive maintenance program is crucial for any organization looking to keep their equipment running smoothly and minimize downtime. By taking a proactive approach to maintenance, companies can prevent costly breakdowns and extend the lifespan of their assets. Here are some tips on how to implement a successful proactive maintenance program.1. Establish a maintenance schedule: One of the first steps in implementing a proactive maintenance program is to establish a regular maintenance schedule. This schedule should outline when different types of maintenance tasks need to be performed, such as routine inspections, lubrication, and equipment cleaning. By following a schedule, maintenance tasks are less likely to be overlooked or forgotten, leading to better equipment reliability.

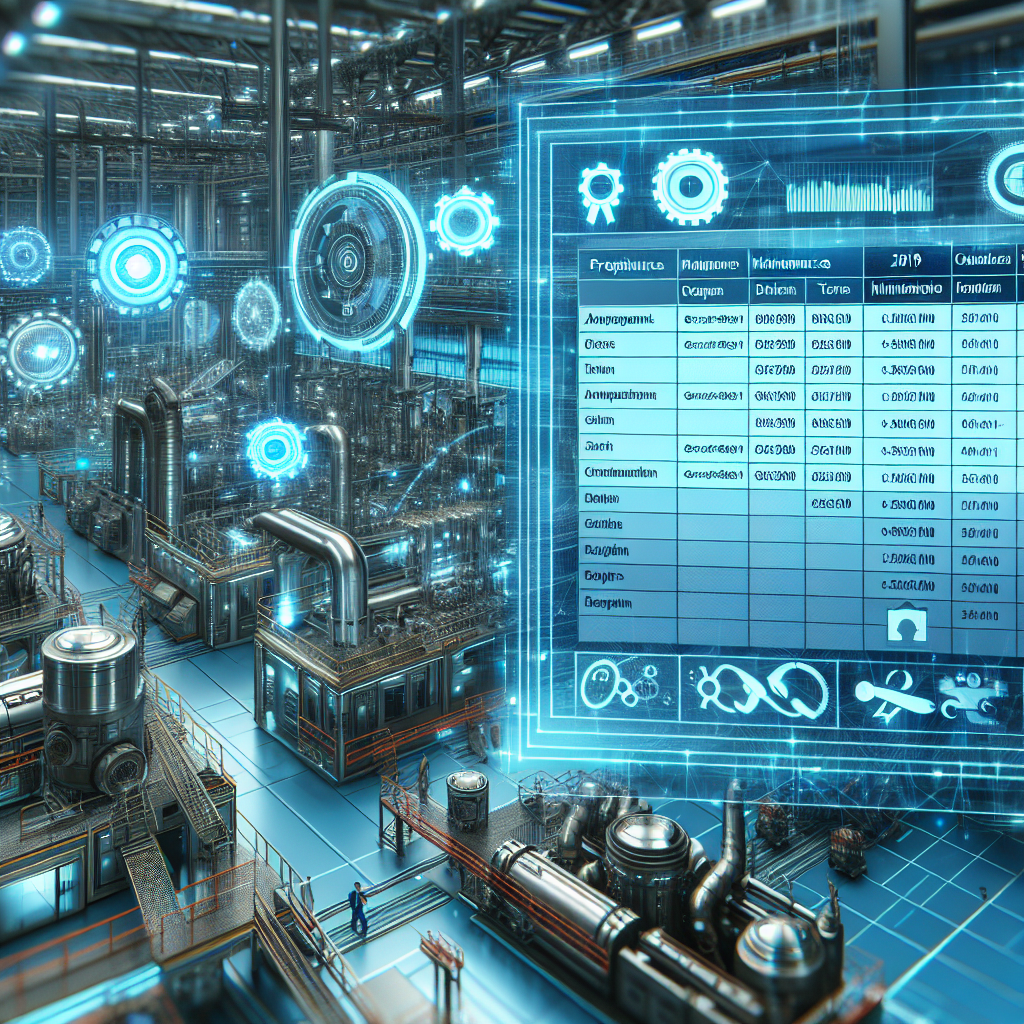

2. Invest in technology: Technology can play a crucial role in a proactive maintenance program. By utilizing tools such as predictive maintenance software, sensors, and monitoring equipment, companies can gather real-time data on the condition of their equipment and identify potential issues before they escalate. This can help prevent unexpected breakdowns and reduce the need for costly repairs.

3. Train your maintenance team: A successful proactive maintenance program relies on a skilled and knowledgeable maintenance team. Make sure to provide your team with the training and resources they need to effectively carry out maintenance tasks. This may include training on equipment operation, maintenance procedures, and how to use maintenance software and tools.

4. Conduct regular inspections: Regular inspections are essential for identifying potential issues before they become serious problems. Inspections should be conducted on a scheduled basis and include checking for signs of wear and tear, leaks, and other issues that could impact equipment performance. By catching issues early, companies can address them before they lead to downtime.

5. Implement a preventive maintenance program: In addition to regular inspections, companies should also implement a preventive maintenance program. This program involves performing maintenance tasks such as equipment calibration, filter replacements, and parts lubrication on a regular basis to prevent issues from occurring. By staying ahead of maintenance tasks, companies can extend the lifespan of their equipment and reduce the risk of unexpected breakdowns.

In conclusion, implementing a successful proactive maintenance program is essential for organizations looking to improve equipment reliability and minimize downtime. By establishing a maintenance schedule, investing in technology, training your maintenance team, conducting regular inspections, and implementing a preventive maintenance program, companies can keep their equipment running smoothly and avoid costly repairs. By taking a proactive approach to maintenance, companies can save time and money in the long run.

Creating a Culture of Proactive Maintenance in Your Facility

Maintenance is a critical aspect of facility management that can greatly impact the efficiency, safety, and overall performance of a building. While reactive maintenance is often necessary to address immediate issues, proactive maintenance is essential for preventing costly repairs, minimizing downtime, and extending the lifespan of equipment and systems. Creating a culture of proactive maintenance in your facility can help you stay ahead of potential problems and keep your operations running smoothly.One of the key elements of creating a culture of proactive maintenance is establishing a comprehensive maintenance plan. This plan should outline the regular inspection, testing, and servicing of all equipment and systems in your facility. By scheduling routine maintenance tasks, you can identify potential issues before they escalate into major problems and address them in a timely manner.

Training and empowering your maintenance staff is also crucial in promoting proactive maintenance. Invest in ongoing training programs to ensure that your team is knowledgeable about the latest technologies, best practices, and safety protocols. Encourage your staff to take ownership of their work and empower them to make decisions that will benefit the facility in the long run.

Utilizing technology can also help streamline the maintenance process and improve efficiency. Implementing a computerized maintenance management system (CMMS) can help track maintenance tasks, schedule work orders, and generate reports on equipment performance. By leveraging technology, you can better prioritize maintenance tasks, allocate resources effectively, and improve communication within your maintenance team.

Regular communication and collaboration between departments is essential for promoting a culture of proactive maintenance. Encourage open dialogue between the maintenance team, operations staff, and management to share insights, address concerns, and coordinate efforts to optimize facility performance. By fostering a collaborative environment, you can leverage the expertise of all stakeholders to identify potential maintenance issues and develop effective solutions.

Incentivizing proactive maintenance can also help motivate your staff to prioritize maintenance tasks and take a proactive approach to facility management. Recognize and reward employees who go above and beyond in maintaining equipment, identifying potential issues, and implementing preventive measures. By incentivizing proactive behavior, you can create a culture that values maintenance as a critical component of facility operations.

Ultimately, creating a culture of proactive maintenance requires a commitment to ongoing training, communication, collaboration, and incentivization. By investing in your maintenance team, utilizing technology, and fostering a collaborative environment, you can prevent costly repairs, minimize downtime, and ensure that your facility operates at peak performance. By prioritizing proactive maintenance, you can create a culture that values efficiency, safety, and sustainability in your facility.

The Role of Proactive Maintenance in Minimizing Downtime and Disruptions

In today’s fast-paced business environment, downtime and disruptions can have a significant impact on the bottom line. Whether it’s a manufacturing plant, a retail store, or an office building, any interruption in operations can result in lost productivity, revenue, and customer satisfaction. That’s why proactive maintenance plays a crucial role in minimizing downtime and disruptions.Proactive maintenance is a preventive approach to maintenance that focuses on identifying and addressing potential issues before they escalate into major problems. By regularly inspecting equipment, performing routine maintenance tasks, and monitoring performance metrics, organizations can proactively address issues and prevent unexpected breakdowns.

One of the key benefits of proactive maintenance is its ability to minimize downtime. By fixing issues before they cause a breakdown, organizations can avoid costly disruptions to operations. This not only saves time and money but also helps maintain a positive reputation with customers and stakeholders.

Additionally, proactive maintenance can help improve the overall reliability and performance of equipment. By regularly maintaining and servicing machinery, organizations can extend the lifespan of their assets and ensure that they operate at peak efficiency. This can result in increased productivity, reduced operating costs, and a higher return on investment.

Another important aspect of proactive maintenance is its ability to improve safety and compliance. By following a proactive maintenance schedule, organizations can ensure that equipment meets regulatory standards and is safe for employees to operate. This can help prevent accidents, injuries, and costly fines associated with non-compliance.

In conclusion, proactive maintenance plays a critical role in minimizing downtime and disruptions in today’s business environment. By taking a proactive approach to maintenance, organizations can improve reliability, performance, and safety, while also reducing costs and increasing productivity. Investing in proactive maintenance is a smart decision that can help organizations stay competitive and successful in the long run.

How Proactive Maintenance Can Improve Efficiency and Productivity

Proactive maintenance is a strategy that focuses on preventing equipment failure before it occurs, rather than waiting for a breakdown to happen and then fixing it. This approach can significantly improve efficiency and productivity in a variety of industries, from manufacturing to healthcare.One of the key benefits of proactive maintenance is that it helps to avoid costly downtime. When equipment breaks down unexpectedly, it can take hours or even days to repair, leading to lost production time and revenue. By regularly inspecting and maintaining equipment, issues can be identified and addressed before they cause a breakdown, reducing the risk of unplanned downtime.

Proactive maintenance also helps to extend the lifespan of equipment. Regular maintenance checks can identify wear and tear on components, allowing them to be replaced or repaired before they fail completely. This not only saves money on expensive repairs, but also prolongs the life of the equipment, reducing the need for costly replacements.

In addition to preventing breakdowns and extending equipment lifespan, proactive maintenance can also improve efficiency and productivity in other ways. For example, by keeping equipment in optimal working condition, it can operate more efficiently, using less energy and resources to perform the same tasks. This can lead to cost savings and increased output.

Furthermore, proactive maintenance can help to improve safety in the workplace. Regular inspections can identify potential hazards or safety risks, allowing them to be addressed before they cause an accident or injury. This not only protects employees, but also helps to avoid costly fines and legal issues that can arise from workplace accidents.

Overall, proactive maintenance is a proactive approach that can have a positive impact on efficiency, productivity, and safety in any industry. By investing in regular maintenance checks and inspections, businesses can reduce downtime, extend equipment lifespan, improve efficiency, and enhance workplace safety. This can lead to cost savings, increased output, and a more efficient and productive operation overall.

Proactive vs. Reactive Maintenance: Why Being Proactive is Crucial

Maintenance is an essential aspect of keeping any system running smoothly and efficiently. However, there are two main approaches to maintenance: proactive and reactive. Proactive maintenance involves taking preventative measures to avoid breakdowns and issues before they occur, while reactive maintenance involves fixing issues as they arise.While reactive maintenance may seem like a quick and easy solution to problems, it is often more costly and time-consuming in the long run. When equipment breaks down unexpectedly, it can lead to costly repairs, downtime, and lost productivity. In contrast, proactive maintenance allows for scheduled maintenance and inspections to identify and address potential issues before they become major problems.

Being proactive with maintenance not only saves time and money but also helps to prolong the lifespan of equipment and machinery. By regularly monitoring and maintaining equipment, businesses can avoid costly repairs and replacements, as well as reduce the risk of unexpected downtime.

Proactive maintenance also promotes a safer work environment. By addressing potential safety hazards before they cause harm, businesses can prevent accidents and injuries in the workplace. This not only protects employees but also helps to maintain compliance with health and safety regulations.

Furthermore, being proactive with maintenance can improve overall efficiency and productivity. When equipment is properly maintained and running smoothly, it can operate at peak performance levels, leading to increased productivity and output. This can ultimately result in higher profits and a competitive edge in the market.

In conclusion, being proactive with maintenance is crucial for businesses to ensure the smooth operation of equipment, reduce costs, maintain a safe work environment, and improve overall efficiency and productivity. By investing in proactive maintenance strategies, businesses can protect their assets, employees, and bottom line.

The Importance of Preventive Maintenance in Avoiding Costly Repairs

Preventive maintenance is an essential aspect of owning and maintaining any type of machinery or equipment. By regularly inspecting, servicing, and repairing equipment before it breaks down, you can avoid costly repairs and downtime that can severely impact your business operations. In this article, we will discuss the importance of preventive maintenance in avoiding costly repairs.One of the primary benefits of preventive maintenance is that it helps to identify and address small issues before they become major problems. By regularly inspecting equipment and identifying any signs of wear and tear, you can address these issues early on and prevent them from escalating into more serious and costly repairs. This can save you both time and money in the long run, as minor repairs are generally much less expensive than major ones.

Additionally, preventive maintenance helps to prolong the lifespan of your equipment. By regularly servicing and maintaining your machinery, you can ensure that it continues to operate efficiently and effectively for as long as possible. This can help you to get the most out of your investment and avoid the need to replace equipment prematurely due to neglect or poor maintenance.

Furthermore, preventive maintenance can help to improve the safety of your workplace. By regularly inspecting equipment and ensuring that it is in good working condition, you can reduce the risk of accidents and injuries caused by malfunctioning machinery. This can help to create a safer work environment for your employees and reduce the likelihood of costly lawsuits or fines resulting from workplace accidents.

In conclusion, preventive maintenance is a crucial aspect of equipment maintenance that can help to avoid costly repairs, prolong the lifespan of your equipment, and improve workplace safety. By investing in regular inspections, servicing, and repairs, you can ensure that your machinery continues to operate efficiently and effectively, saving you time and money in the long run. So, make sure to prioritize preventive maintenance in your maintenance schedule to avoid costly repairs and keep your equipment running smoothly.

The ROI of Proactive Maintenance: Investing in the Future of Your Equipment

As a business owner, you understand the importance of keeping your equipment in top working condition. After all, your equipment is the lifeblood of your operation, and any downtime can result in lost productivity and revenue. But have you considered the return on investment of proactive maintenance?Proactive maintenance is a strategy that involves regularly inspecting and servicing equipment before any issues arise. By taking a proactive approach to maintenance, you can prevent costly breakdowns, extend the lifespan of your equipment, and improve overall efficiency.

One of the key benefits of proactive maintenance is the potential for cost savings. By addressing small issues before they escalate into major problems, you can avoid expensive repairs and replacements. Additionally, regular maintenance can help identify areas where efficiency can be improved, leading to lower energy costs and increased productivity.

Another important aspect of proactive maintenance is the impact it can have on the lifespan of your equipment. By keeping your equipment well-maintained, you can extend its lifespan and delay the need for costly replacements. This can result in significant long-term savings and help you get the most out of your investment.

In addition to cost savings and increased equipment lifespan, proactive maintenance can also improve safety in the workplace. Regular inspections and maintenance can help identify potential safety hazards and prevent accidents before they occur. This not only protects your employees, but also reduces the risk of costly liability claims.

Investing in proactive maintenance is an investment in the future of your equipment and your business. By taking a proactive approach to maintenance, you can save money, extend the lifespan of your equipment, and improve safety in the workplace. So, don’t wait for a breakdown to occur – start investing in proactive maintenance today and reap the benefits for years to come.

Proactive Maintenance Best Practices for Long-Term Success

Proactive maintenance is an essential aspect of ensuring the long-term success of any business. By implementing best practices for proactive maintenance, companies can minimize downtime, reduce costs, and increase the lifespan of their equipment and assets. In this article, we will discuss some key best practices for proactive maintenance that can help businesses achieve long-term success.1. Develop a maintenance schedule: One of the first steps in implementing proactive maintenance is to develop a maintenance schedule. This schedule should outline when maintenance tasks need to be performed, who is responsible for performing them, and what resources are required. By having a structured maintenance schedule in place, businesses can ensure that maintenance tasks are performed regularly and on time.

2. Conduct regular inspections: Regular inspections are essential for identifying potential issues before they escalate into costly problems. By conducting routine inspections of equipment and assets, businesses can identify wear and tear, leaks, and other issues early on, allowing them to address them before they cause downtime or damage.

3. Implement predictive maintenance techniques: Predictive maintenance involves using technology and data to predict when equipment is likely to fail. By implementing predictive maintenance techniques, businesses can schedule maintenance tasks more efficiently, reduce downtime, and extend the lifespan of their equipment.

4. Train maintenance staff: Proper training is essential for maintenance staff to effectively perform their duties. By providing ongoing training and education to maintenance staff, businesses can ensure that they have the skills and knowledge required to perform maintenance tasks effectively and efficiently.

5. Use technology to streamline maintenance processes: Technology can play a key role in streamlining maintenance processes and improving efficiency. By using maintenance management software, businesses can track maintenance tasks, schedule maintenance activities, and generate reports to monitor equipment performance and maintenance trends.

6. Keep detailed maintenance records: Keeping detailed maintenance records is essential for tracking maintenance activities, identifying trends, and making informed decisions about maintenance practices. By maintaining accurate and up-to-date maintenance records, businesses can ensure that maintenance tasks are performed on time and that equipment is properly maintained.

In conclusion, proactive maintenance is crucial for the long-term success of any business. By implementing best practices for proactive maintenance, businesses can minimize downtime, reduce costs, and increase the lifespan of their equipment and assets. By developing a maintenance schedule, conducting regular inspections, implementing predictive maintenance techniques, training maintenance staff, using technology to streamline maintenance processes, and keeping detailed maintenance records, businesses can ensure that their equipment and assets are well-maintained and operating at peak performance.

Proactive Maintenance: A Key Component of Efficient Operations

Proactive maintenance is a crucial aspect of ensuring that operations run smoothly and efficiently in any organization. By taking a proactive approach to maintenance, businesses can prevent costly breakdowns, reduce downtime, and extend the lifespan of their equipment and machinery. This ultimately leads to increased productivity, lower maintenance costs, and improved overall performance.One of the key benefits of proactive maintenance is that it allows businesses to identify and address potential issues before they escalate into major problems. By regularly inspecting and maintaining equipment, businesses can catch small issues early on and make the necessary repairs or replacements before they cause a breakdown. This not only saves time and money, but also prevents disruptions to production schedules and ensures that operations can continue running smoothly.

Proactive maintenance also helps businesses to extend the lifespan of their equipment. By keeping machinery well-maintained and operating at peak performance, businesses can avoid premature wear and tear that can lead to costly replacements. Regular maintenance can help to improve the efficiency of equipment, reduce energy consumption, and prolong its useful life, ultimately saving money in the long run.

Furthermore, proactive maintenance can help businesses to plan and budget for maintenance activities more effectively. By scheduling regular maintenance tasks in advance, businesses can avoid unexpected costs and downtime associated with emergency repairs. This allows businesses to better allocate resources, plan for maintenance expenses, and optimize their maintenance schedules to minimize disruptions to operations.

In order to implement an effective proactive maintenance program, businesses should establish a comprehensive maintenance plan that outlines the tasks, schedules, and procedures for maintaining equipment. This may include regular inspections, lubrication, cleaning, calibration, and testing of equipment to ensure that it is operating properly. Businesses should also invest in training for maintenance staff to ensure that they have the skills and knowledge to carry out maintenance tasks effectively.

In conclusion, proactive maintenance is a key component of efficient operations in any organization. By taking a proactive approach to maintenance, businesses can prevent costly breakdowns, extend the lifespan of their equipment, and improve overall performance. By implementing a comprehensive maintenance plan and investing in training for maintenance staff, businesses can ensure that their operations run smoothly and efficiently, ultimately leading to increased productivity and reduced maintenance costs.

The Benefits of Implementing a Proactive Maintenance Plan

Implementing a proactive maintenance plan is crucial for businesses looking to reduce downtime, improve equipment reliability, and increase overall efficiency. By taking a proactive approach to maintenance, companies can address potential issues before they escalate into costly problems, ultimately saving time and money in the long run.One of the key benefits of implementing a proactive maintenance plan is the ability to prevent equipment failures before they occur. By regularly inspecting and maintaining equipment, businesses can identify and address issues early on, preventing unexpected breakdowns that can disrupt operations and lead to costly repairs. This proactive approach can also help extend the lifespan of equipment, reducing the need for premature replacements and saving businesses money in the long term.

In addition to preventing equipment failures, a proactive maintenance plan can also help businesses improve overall equipment reliability. By consistently monitoring and maintaining equipment, businesses can identify and address potential issues that could impact performance, ensuring that equipment operates at peak efficiency. This not only helps businesses avoid unexpected downtime but also improves productivity and reduces the risk of costly repairs.

Furthermore, implementing a proactive maintenance plan can help businesses improve safety in the workplace. Regularly inspecting and maintaining equipment can help identify potential safety hazards, allowing businesses to address them before they pose a risk to employees. By prioritizing safety through proactive maintenance, businesses can create a safer work environment for their employees and reduce the likelihood of accidents or injuries.

Overall, implementing a proactive maintenance plan can have a positive impact on a business’s bottom line. By preventing equipment failures, improving equipment reliability, and enhancing workplace safety, businesses can reduce downtime, increase productivity, and save money on costly repairs. With the benefits of proactive maintenance clear, businesses should prioritize implementing a proactive maintenance plan to ensure the long-term success and efficiency of their operations.