Your cart is currently empty!

Tag: Proactive

The ROI of Proactive Maintenance: Investing in the Future of Your Equipment

As a business owner, you understand the importance of keeping your equipment in top working condition. After all, your equipment is the lifeblood of your operation, and any downtime can result in lost productivity and revenue. But have you considered the return on investment of proactive maintenance?Proactive maintenance is a strategy that involves regularly inspecting and servicing equipment before any issues arise. By taking a proactive approach to maintenance, you can prevent costly breakdowns, extend the lifespan of your equipment, and improve overall efficiency.

One of the key benefits of proactive maintenance is the potential for cost savings. By addressing small issues before they escalate into major problems, you can avoid expensive repairs and replacements. Additionally, regular maintenance can help identify areas where efficiency can be improved, leading to lower energy costs and increased productivity.

Another important aspect of proactive maintenance is the impact it can have on the lifespan of your equipment. By keeping your equipment well-maintained, you can extend its lifespan and delay the need for costly replacements. This can result in significant long-term savings and help you get the most out of your investment.

In addition to cost savings and increased equipment lifespan, proactive maintenance can also improve safety in the workplace. Regular inspections and maintenance can help identify potential safety hazards and prevent accidents before they occur. This not only protects your employees, but also reduces the risk of costly liability claims.

Investing in proactive maintenance is an investment in the future of your equipment and your business. By taking a proactive approach to maintenance, you can save money, extend the lifespan of your equipment, and improve safety in the workplace. So, don’t wait for a breakdown to occur – start investing in proactive maintenance today and reap the benefits for years to come.

Proactive Maintenance Best Practices for Long-Term Success

Proactive maintenance is an essential aspect of ensuring the long-term success of any business. By implementing best practices for proactive maintenance, companies can minimize downtime, reduce costs, and increase the lifespan of their equipment and assets. In this article, we will discuss some key best practices for proactive maintenance that can help businesses achieve long-term success.1. Develop a maintenance schedule: One of the first steps in implementing proactive maintenance is to develop a maintenance schedule. This schedule should outline when maintenance tasks need to be performed, who is responsible for performing them, and what resources are required. By having a structured maintenance schedule in place, businesses can ensure that maintenance tasks are performed regularly and on time.

2. Conduct regular inspections: Regular inspections are essential for identifying potential issues before they escalate into costly problems. By conducting routine inspections of equipment and assets, businesses can identify wear and tear, leaks, and other issues early on, allowing them to address them before they cause downtime or damage.

3. Implement predictive maintenance techniques: Predictive maintenance involves using technology and data to predict when equipment is likely to fail. By implementing predictive maintenance techniques, businesses can schedule maintenance tasks more efficiently, reduce downtime, and extend the lifespan of their equipment.

4. Train maintenance staff: Proper training is essential for maintenance staff to effectively perform their duties. By providing ongoing training and education to maintenance staff, businesses can ensure that they have the skills and knowledge required to perform maintenance tasks effectively and efficiently.

5. Use technology to streamline maintenance processes: Technology can play a key role in streamlining maintenance processes and improving efficiency. By using maintenance management software, businesses can track maintenance tasks, schedule maintenance activities, and generate reports to monitor equipment performance and maintenance trends.

6. Keep detailed maintenance records: Keeping detailed maintenance records is essential for tracking maintenance activities, identifying trends, and making informed decisions about maintenance practices. By maintaining accurate and up-to-date maintenance records, businesses can ensure that maintenance tasks are performed on time and that equipment is properly maintained.

In conclusion, proactive maintenance is crucial for the long-term success of any business. By implementing best practices for proactive maintenance, businesses can minimize downtime, reduce costs, and increase the lifespan of their equipment and assets. By developing a maintenance schedule, conducting regular inspections, implementing predictive maintenance techniques, training maintenance staff, using technology to streamline maintenance processes, and keeping detailed maintenance records, businesses can ensure that their equipment and assets are well-maintained and operating at peak performance.

Proactive Maintenance: A Key Component of Efficient Operations

Proactive maintenance is a crucial aspect of ensuring that operations run smoothly and efficiently in any organization. By taking a proactive approach to maintenance, businesses can prevent costly breakdowns, reduce downtime, and extend the lifespan of their equipment and machinery. This ultimately leads to increased productivity, lower maintenance costs, and improved overall performance.One of the key benefits of proactive maintenance is that it allows businesses to identify and address potential issues before they escalate into major problems. By regularly inspecting and maintaining equipment, businesses can catch small issues early on and make the necessary repairs or replacements before they cause a breakdown. This not only saves time and money, but also prevents disruptions to production schedules and ensures that operations can continue running smoothly.

Proactive maintenance also helps businesses to extend the lifespan of their equipment. By keeping machinery well-maintained and operating at peak performance, businesses can avoid premature wear and tear that can lead to costly replacements. Regular maintenance can help to improve the efficiency of equipment, reduce energy consumption, and prolong its useful life, ultimately saving money in the long run.

Furthermore, proactive maintenance can help businesses to plan and budget for maintenance activities more effectively. By scheduling regular maintenance tasks in advance, businesses can avoid unexpected costs and downtime associated with emergency repairs. This allows businesses to better allocate resources, plan for maintenance expenses, and optimize their maintenance schedules to minimize disruptions to operations.

In order to implement an effective proactive maintenance program, businesses should establish a comprehensive maintenance plan that outlines the tasks, schedules, and procedures for maintaining equipment. This may include regular inspections, lubrication, cleaning, calibration, and testing of equipment to ensure that it is operating properly. Businesses should also invest in training for maintenance staff to ensure that they have the skills and knowledge to carry out maintenance tasks effectively.

In conclusion, proactive maintenance is a key component of efficient operations in any organization. By taking a proactive approach to maintenance, businesses can prevent costly breakdowns, extend the lifespan of their equipment, and improve overall performance. By implementing a comprehensive maintenance plan and investing in training for maintenance staff, businesses can ensure that their operations run smoothly and efficiently, ultimately leading to increased productivity and reduced maintenance costs.

Best Practices for Delivering Proactive Technical Support to Customers

In today’s fast-paced and technology-driven world, providing proactive technical support to customers is essential for ensuring customer satisfaction and loyalty. By anticipating and addressing potential issues before they arise, companies can not only prevent problems from occurring but also build trust with their customers. Here are some best practices for delivering proactive technical support to customers:1. Conduct Regular System Checks: One of the most effective ways to provide proactive technical support is to conduct regular system checks on your customers’ devices or software. By monitoring for any potential issues or vulnerabilities, you can address them before they become major problems.

2. Implement Remote Monitoring Tools: Remote monitoring tools allow you to keep an eye on your customers’ systems in real-time, enabling you to detect and resolve issues before they impact the customer’s experience. These tools can also help you identify trends and patterns that may indicate potential problems in the future.

3. Provide Self-Help Resources: Empowering customers to troubleshoot and resolve common issues on their own can reduce the number of support tickets and improve customer satisfaction. Providing self-help resources such as knowledge base articles, FAQs, and video tutorials can help customers resolve issues quickly and easily.

4. Offer Proactive Alerts and Notifications: Implementing proactive alerts and notifications can help customers stay informed about potential issues or updates that may impact their systems. This can include alerts for security vulnerabilities, software updates, or upcoming maintenance windows.

5. Personalize Support: Personalizing support for customers by understanding their unique needs and preferences can help build stronger relationships and improve customer satisfaction. By keeping track of previous interactions and preferences, you can provide tailored support that meets their specific requirements.

6. Train Support Staff: Providing comprehensive training to your support staff is crucial for delivering proactive technical support. Ensure that your team is well-versed in the products or services you offer, as well as best practices for troubleshooting and resolving issues proactively.

7. Collect Customer Feedback: Gathering feedback from customers about their experiences with your technical support services can help you identify areas for improvement and refine your proactive support strategies. Encourage customers to provide feedback through surveys, reviews, or direct communication channels.

In conclusion, delivering proactive technical support to customers is essential for maintaining customer satisfaction and loyalty. By implementing these best practices, companies can anticipate and address potential issues before they arise, ultimately enhancing the overall customer experience.

The Benefits of Implementing a Proactive Maintenance Plan

Implementing a proactive maintenance plan is crucial for businesses looking to reduce downtime, improve equipment reliability, and increase overall efficiency. By taking a proactive approach to maintenance, companies can address potential issues before they escalate into costly problems, ultimately saving time and money in the long run.One of the key benefits of implementing a proactive maintenance plan is the ability to prevent equipment failures before they occur. By regularly inspecting and maintaining equipment, businesses can identify and address issues early on, preventing unexpected breakdowns that can disrupt operations and lead to costly repairs. This proactive approach can also help extend the lifespan of equipment, reducing the need for premature replacements and saving businesses money in the long term.

In addition to preventing equipment failures, a proactive maintenance plan can also help businesses improve overall equipment reliability. By consistently monitoring and maintaining equipment, businesses can identify and address potential issues that could impact performance, ensuring that equipment operates at peak efficiency. This not only helps businesses avoid unexpected downtime but also improves productivity and reduces the risk of costly repairs.

Furthermore, implementing a proactive maintenance plan can help businesses improve safety in the workplace. Regularly inspecting and maintaining equipment can help identify potential safety hazards, allowing businesses to address them before they pose a risk to employees. By prioritizing safety through proactive maintenance, businesses can create a safer work environment for their employees and reduce the likelihood of accidents or injuries.

Overall, implementing a proactive maintenance plan can have a positive impact on a business’s bottom line. By preventing equipment failures, improving equipment reliability, and enhancing workplace safety, businesses can reduce downtime, increase productivity, and save money on costly repairs. With the benefits of proactive maintenance clear, businesses should prioritize implementing a proactive maintenance plan to ensure the long-term success and efficiency of their operations.

Maximizing Equipment Lifespan through Proactive Maintenance Strategies

Equipment maintenance is a crucial aspect of any business operation, as it directly impacts the lifespan and performance of machinery and tools. By implementing proactive maintenance strategies, businesses can maximize the lifespan of their equipment, reduce downtime, and ultimately save money in the long run.Proactive maintenance involves regularly monitoring and servicing equipment before any issues arise, rather than waiting for a breakdown to occur. This approach allows businesses to identify potential problems early on and address them before they escalate into costly repairs or replacements.

One of the key proactive maintenance strategies is regular inspections. By conducting routine checks on equipment, businesses can identify any signs of wear and tear, loose parts, or other issues that may affect performance. This allows maintenance teams to address these issues promptly and prevent them from causing more significant problems down the line.

Another important proactive maintenance strategy is implementing a preventive maintenance schedule. This involves scheduling regular maintenance tasks, such as lubrication, filter changes, and calibration, to ensure equipment is running smoothly and efficiently. By staying on top of these routine tasks, businesses can prevent breakdowns and extend the lifespan of their equipment.

Additionally, businesses can utilize predictive maintenance techniques to anticipate potential issues before they occur. This involves using data and analytics to monitor the performance of equipment and identify patterns or trends that may indicate a future problem. By proactively addressing these issues, businesses can prevent unexpected breakdowns and keep their equipment running at optimal levels.

Overall, proactive maintenance strategies are essential for maximizing the lifespan of equipment and ensuring smooth operations. By investing time and resources into regular inspections, preventive maintenance, and predictive maintenance techniques, businesses can extend the lifespan of their equipment, reduce downtime, and ultimately save money in the long run. In today’s competitive business environment, proactive maintenance is a smart investment that can pay off in the form of increased efficiency, productivity, and profitability.

The Evolution of Managed Service Providers: From Break-Fix to Proactive IT Solutions

Managed Service Providers (MSPs) have come a long way since the early days of break-fix IT support. In the past, businesses would only call on IT support when something went wrong, resulting in costly downtime and lost productivity. However, as technology has evolved, so too have the services offered by MSPs.The shift from break-fix to proactive IT solutions has been driven by the increasing complexity of technology and the need for businesses to stay ahead of the curve. MSPs now offer a range of services designed to prevent issues before they occur, such as network monitoring, security audits, and regular software updates.

One of the key benefits of proactive IT solutions is the ability to predict and prevent problems before they impact the business. This not only reduces downtime and IT costs but also allows businesses to focus on their core operations without worrying about technical issues.

Another significant evolution in the MSP industry is the move towards cloud-based solutions. Cloud computing offers businesses greater flexibility, scalability, and cost-efficiency compared to traditional on-premise IT infrastructure. MSPs now offer a range of cloud services, including cloud storage, backup, and disaster recovery, to help businesses leverage the power of the cloud.

Furthermore, the rise of remote work has also shaped the services offered by MSPs. With more employees working from home, businesses need secure and reliable IT solutions to support their remote workforce. MSPs now offer remote monitoring and management services, as well as cybersecurity solutions to protect sensitive data from cyber threats.

Overall, the evolution of Managed Service Providers from break-fix to proactive IT solutions has been driven by the changing needs of businesses and advancements in technology. By partnering with an MSP, businesses can benefit from a range of services designed to keep their IT systems running smoothly and securely, allowing them to focus on their core operations and drive growth.

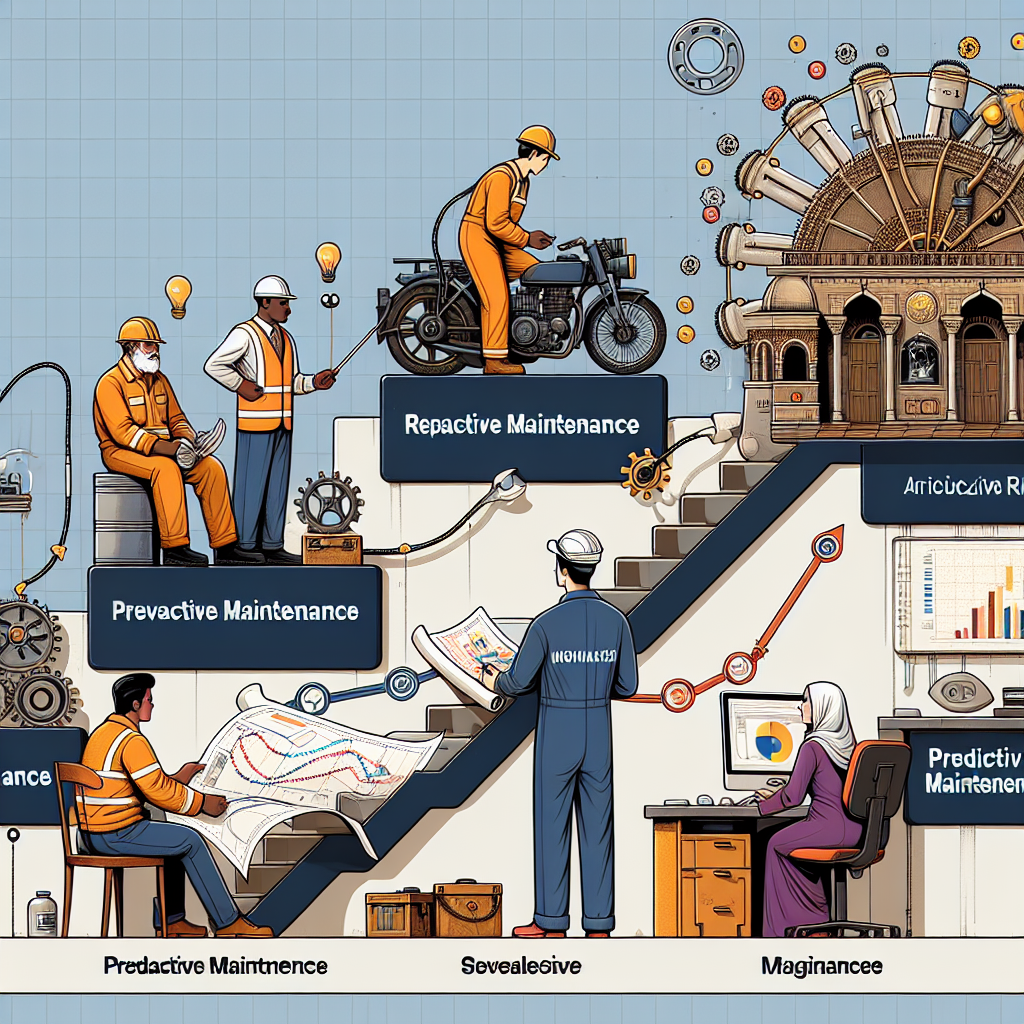

The Evolution of Maintenance: Embracing Proactive Strategies for Success

Maintenance has always been a crucial aspect of ensuring the longevity and efficiency of equipment, machinery, and infrastructure. Traditionally, maintenance strategies have been reactive in nature, meaning that maintenance activities are performed in response to equipment failures or breakdowns. However, as industries and technologies continue to evolve, so too must maintenance practices. In today’s fast-paced and competitive business environment, proactive maintenance strategies have become essential for success.The evolution of maintenance from reactive to proactive approaches has been driven by several factors. One of the key drivers is the increasing complexity and sophistication of modern equipment and machinery. With the advent of advanced technologies such as IoT, AI, and predictive analytics, equipment is now capable of providing real-time data on its performance and condition. This data can be used to predict potential failures before they occur, allowing maintenance teams to proactively address issues and prevent costly downtime.

Another factor driving the shift towards proactive maintenance is the growing emphasis on sustainability and environmental responsibility. By adopting proactive maintenance strategies, organizations can minimize their environmental impact by reducing energy consumption, waste, and emissions. Proactive maintenance also helps to extend the lifespan of equipment, reducing the need for frequent replacements and the associated environmental costs.

In addition to these factors, the increasing pressure to optimize operational efficiency and reduce costs has also played a role in the adoption of proactive maintenance strategies. By preventing breakdowns and improving equipment reliability, proactive maintenance can help organizations maximize productivity, minimize downtime, and reduce maintenance costs in the long run.

So, what does proactive maintenance look like in practice? Proactive maintenance involves a shift from reactive, time-based maintenance schedules to condition-based maintenance. This means monitoring equipment in real-time to detect anomalies and potential issues, and taking corrective action before they escalate into major problems. Predictive maintenance techniques, such as vibration analysis, thermal imaging, and oil analysis, can be used to identify early warning signs of equipment failures and schedule maintenance activities accordingly.

Furthermore, proactive maintenance also involves a focus on continuous improvement and optimization. By analyzing maintenance data and performance metrics, organizations can identify trends and patterns that can help them fine-tune their maintenance strategies and improve overall equipment reliability.

In conclusion, the evolution of maintenance towards proactive strategies is essential for organizations looking to stay ahead in today’s competitive business landscape. By embracing proactive maintenance approaches, organizations can improve equipment reliability, reduce downtime, minimize costs, and enhance operational efficiency. As technology continues to advance and industries become increasingly complex, proactive maintenance will be a key differentiator for success in the future.

Improving Reliability with Proactive Maintenance Techniques

Reliability is a key factor in the success of any organization, especially in industries where downtime can have significant financial and operational implications. Proactive maintenance techniques are essential for improving reliability and ensuring that equipment and systems operate efficiently and effectively.Proactive maintenance involves taking a proactive approach to maintenance rather than waiting for equipment to fail before taking action. By implementing proactive maintenance techniques, organizations can prevent unexpected breakdowns, reduce downtime, and increase the lifespan of equipment.

One of the most effective proactive maintenance techniques is predictive maintenance, which involves using data and analytics to predict when equipment is likely to fail. By monitoring the condition of equipment and analyzing data on factors such as temperature, vibration, and performance, organizations can identify potential issues before they escalate into major problems.

Another proactive maintenance technique is preventive maintenance, which involves regularly scheduled maintenance tasks to keep equipment in good working condition. By performing routine inspections, lubrication, and adjustments, organizations can prevent equipment failures and ensure that systems operate at optimal levels.

Reliability-centered maintenance (RCM) is another proactive maintenance technique that focuses on identifying the most critical components of a system and developing maintenance strategies to ensure their reliability. By prioritizing maintenance tasks based on the criticality of equipment, organizations can allocate resources effectively and reduce the risk of unexpected failures.

Overall equipment effectiveness (OEE) is another important metric that organizations can use to measure the reliability of their equipment. By tracking factors such as availability, performance, and quality, organizations can identify areas for improvement and implement proactive maintenance techniques to increase reliability.

In addition to these proactive maintenance techniques, organizations can also improve reliability by investing in training and development for maintenance staff, implementing a computerized maintenance management system (CMMS) to track maintenance activities, and conducting regular audits and assessments of maintenance processes.

In conclusion, improving reliability with proactive maintenance techniques is essential for organizations looking to reduce downtime, increase equipment lifespan, and optimize operational efficiency. By implementing predictive maintenance, preventive maintenance, RCM, OEE, and other proactive maintenance strategies, organizations can ensure that their equipment operates reliably and effectively, leading to increased productivity and cost savings in the long run.

Proactive Maintenance: A Strategic Approach to Asset Management

Proactive maintenance is a strategic approach to asset management that focuses on preventing equipment failures before they occur. This approach involves regularly monitoring equipment, identifying potential issues, and taking corrective action to avoid costly downtime and repairs.One of the key benefits of proactive maintenance is that it can help organizations save time and money by reducing the number of unexpected breakdowns. By regularly inspecting equipment and addressing any issues early on, companies can avoid costly repairs and minimize downtime, which can have a significant impact on productivity and profitability.

Proactive maintenance also helps organizations extend the lifespan of their assets. By regularly maintaining equipment and addressing any issues promptly, companies can ensure that their assets operate at peak performance levels for longer periods of time. This can help organizations maximize the return on their investment in equipment and reduce the need for frequent replacements.

In addition to cost savings and improved asset lifespan, proactive maintenance can also help organizations improve their overall operational efficiency. By identifying and addressing potential issues before they lead to equipment failures, companies can reduce the risk of production disruptions and ensure that their operations run smoothly and efficiently.

To implement a proactive maintenance strategy, organizations can use a variety of tools and techniques, including predictive maintenance technologies, asset management software, and regular equipment inspections. By combining these tools and techniques, companies can create a comprehensive maintenance program that helps them identify and address potential issues before they become major problems.

Overall, proactive maintenance is a critical component of effective asset management. By taking a strategic approach to maintenance and focusing on prevention rather than reaction, organizations can save time and money, extend the lifespan of their assets, and improve their overall operational efficiency. Investing in proactive maintenance can help companies stay ahead of potential issues and ensure that their operations run smoothly and efficiently.