Maintenance is a crucial aspect of any business operation, as it ensures that equipment and machinery are functioning at their optimal level. When it comes to maintenance strategies, there are two main approaches: proactive and reactive maintenance. While both have their merits, there is a strong case for being proactive when it comes to maintaining equipment.

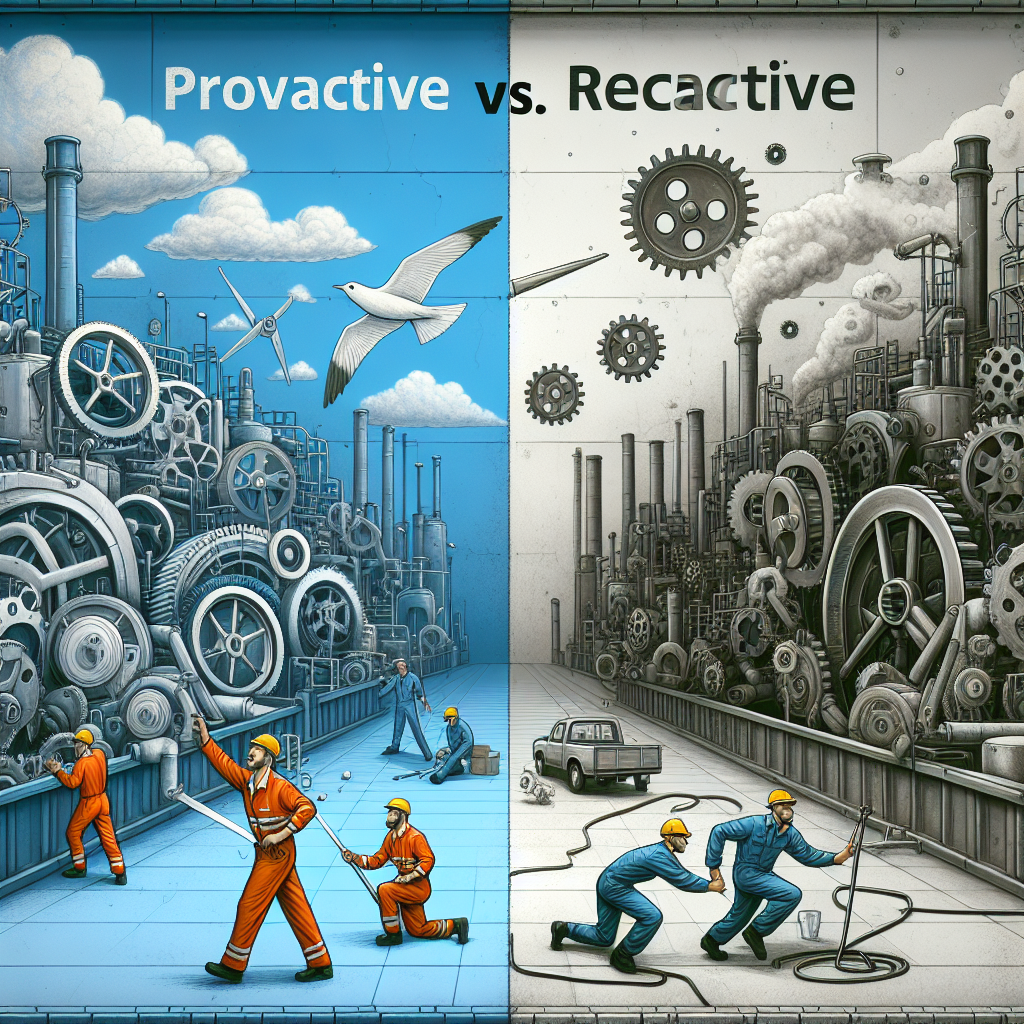

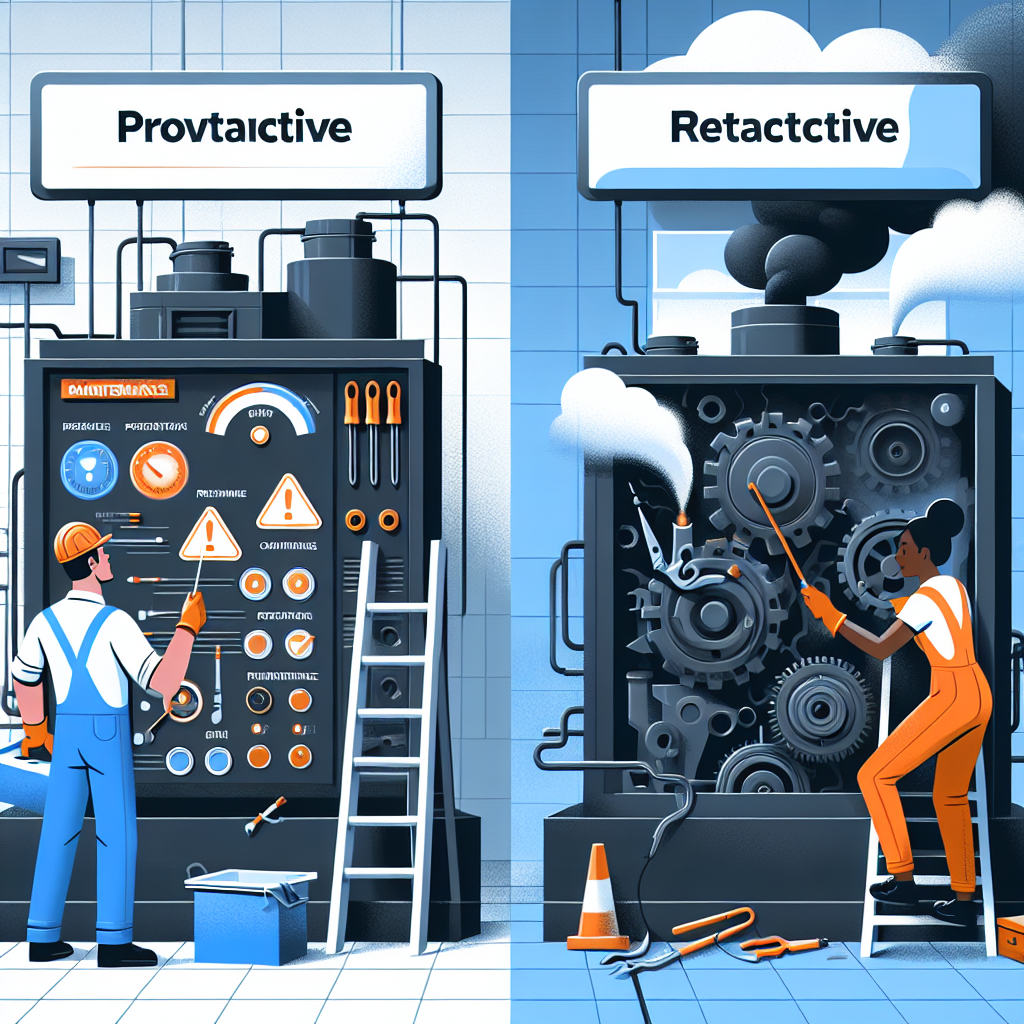

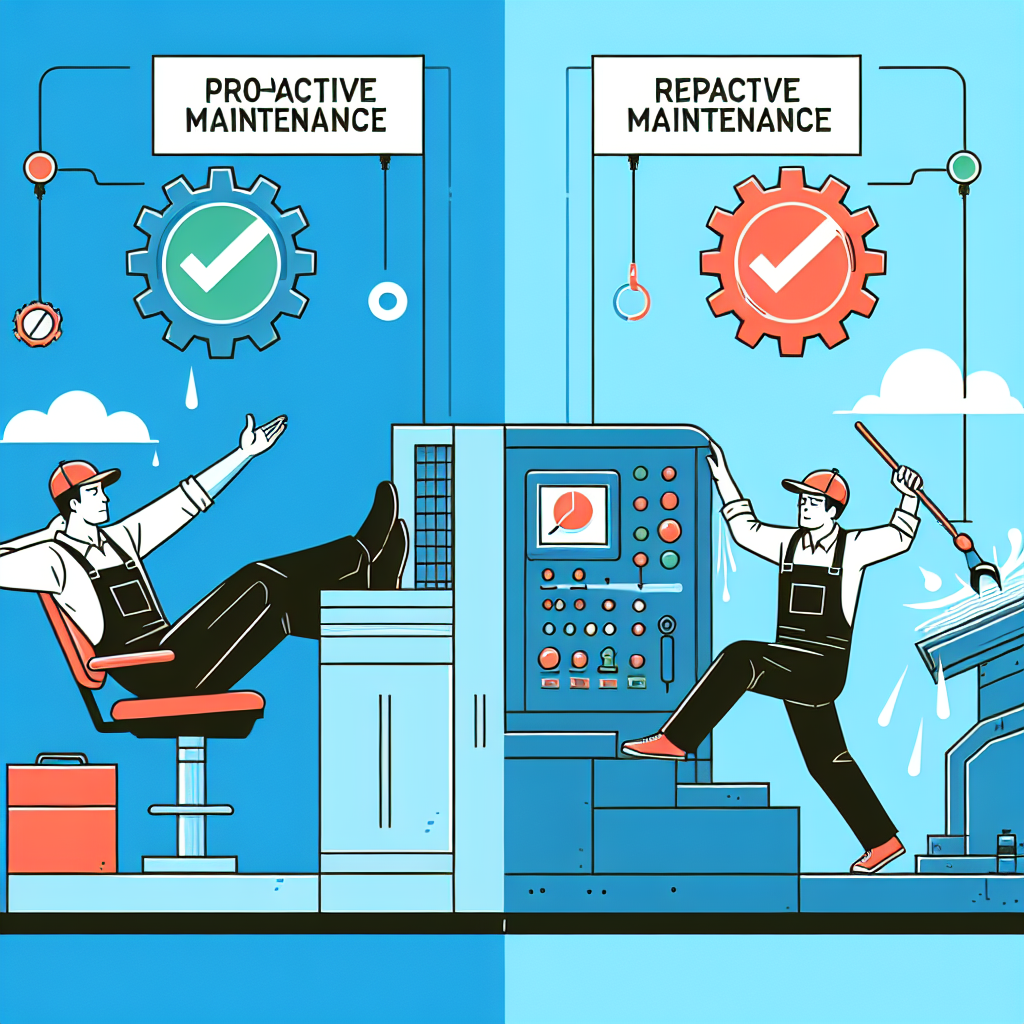

Proactive maintenance involves regularly scheduled inspections and preventive measures to keep equipment in good working condition. This approach aims to identify and address potential issues before they become major problems, ultimately reducing downtime and increasing the lifespan of equipment.

On the other hand, reactive maintenance involves addressing issues only when they arise, often resulting in unexpected breakdowns and costly repairs. While reactive maintenance may seem like a cost-effective approach in the short term, it can lead to higher overall costs in the long run due to lost productivity and increased repair expenses.

There are several reasons why being proactive with maintenance is the better choice for businesses. First and foremost, proactive maintenance helps to prevent costly breakdowns and repairs by addressing issues before they escalate. By regularly inspecting equipment and performing preventive maintenance tasks, businesses can avoid unexpected downtime and keep operations running smoothly.

Additionally, proactive maintenance can help to improve the overall efficiency and performance of equipment. By keeping machinery in good working condition, businesses can ensure that they are operating at their optimal level, leading to increased productivity and profitability.

Furthermore, proactive maintenance can also help to extend the lifespan of equipment. By regularly servicing and maintaining machinery, businesses can prolong the life of their assets and reduce the need for costly replacements.

Overall, being proactive with maintenance is a wise investment for businesses looking to reduce costs, improve efficiency, and maximize the lifespan of their equipment. By taking a proactive approach to maintenance, businesses can avoid costly breakdowns, improve performance, and ultimately, increase their bottom line.