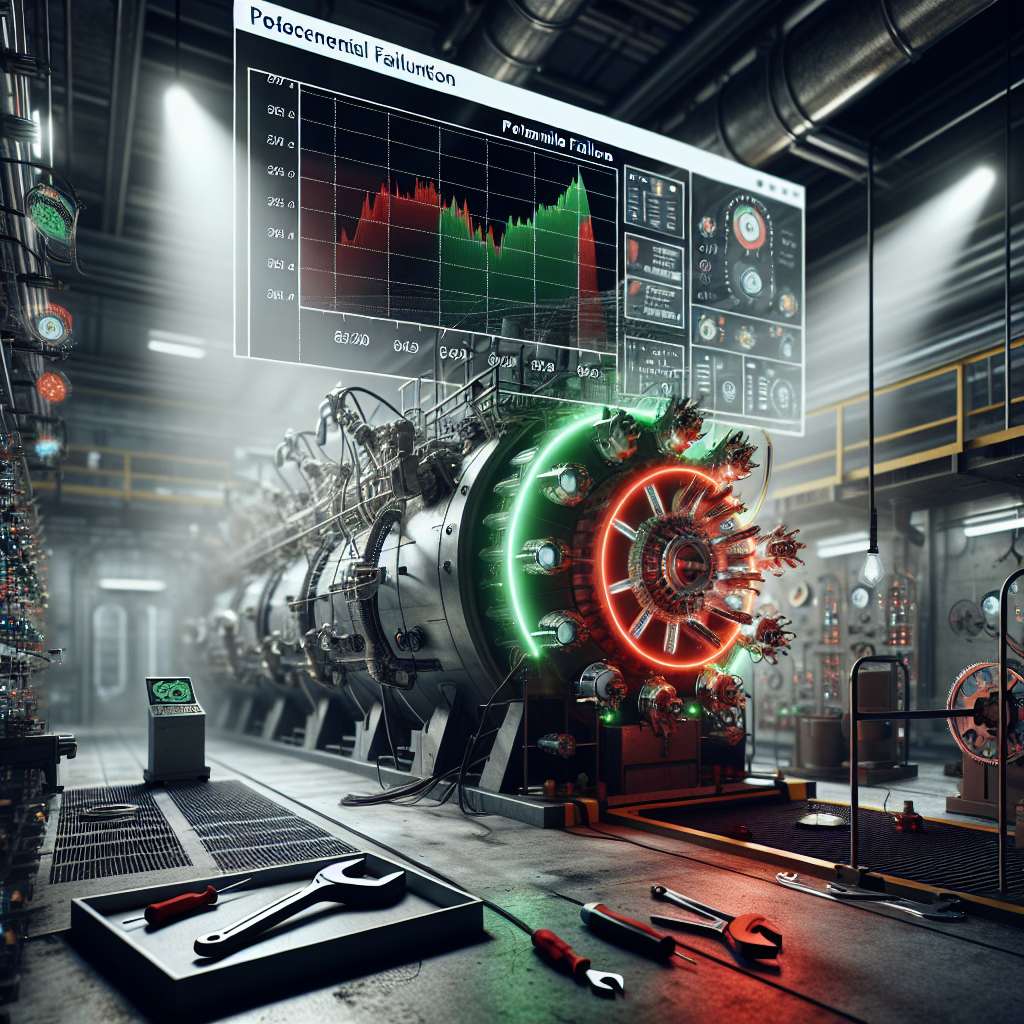

Predictive maintenance is a powerful tool that allows companies to stay ahead of equipment failures by predicting when maintenance is needed before a breakdown occurs. By utilizing data and analytics, companies can monitor the condition of their equipment and identify potential issues before they become serious problems.

One of the key benefits of predictive maintenance is that it helps companies avoid unexpected downtime and costly repairs. By monitoring equipment in real-time, companies can schedule maintenance at the most convenient time, reducing the impact on production and minimizing disruptions to operations.

In addition to preventing breakdowns, predictive maintenance can also extend the lifespan of equipment. By identifying and addressing issues early on, companies can reduce wear and tear on their equipment, ultimately saving money on replacement and repair costs.

Another advantage of predictive maintenance is that it allows companies to optimize their maintenance schedules. Instead of following a fixed schedule, companies can tailor their maintenance activities based on the actual condition of their equipment. This not only saves time and resources but also ensures that maintenance is performed only when necessary.

To implement a successful predictive maintenance program, companies need to invest in the right technology and tools. This may include sensors and monitoring devices that collect data on equipment performance, as well as software that analyzes this data and predicts when maintenance is needed.

It is also important for companies to train their employees on how to use predictive maintenance tools effectively. This may involve providing training on how to interpret data, identify potential issues, and schedule maintenance activities accordingly.

Overall, predictive maintenance is a powerful tool that can help companies stay ahead of equipment failures and ensure the smooth operation of their facilities. By investing in the right technology and training, companies can proactively address maintenance issues and avoid costly downtime.

Leave a Reply