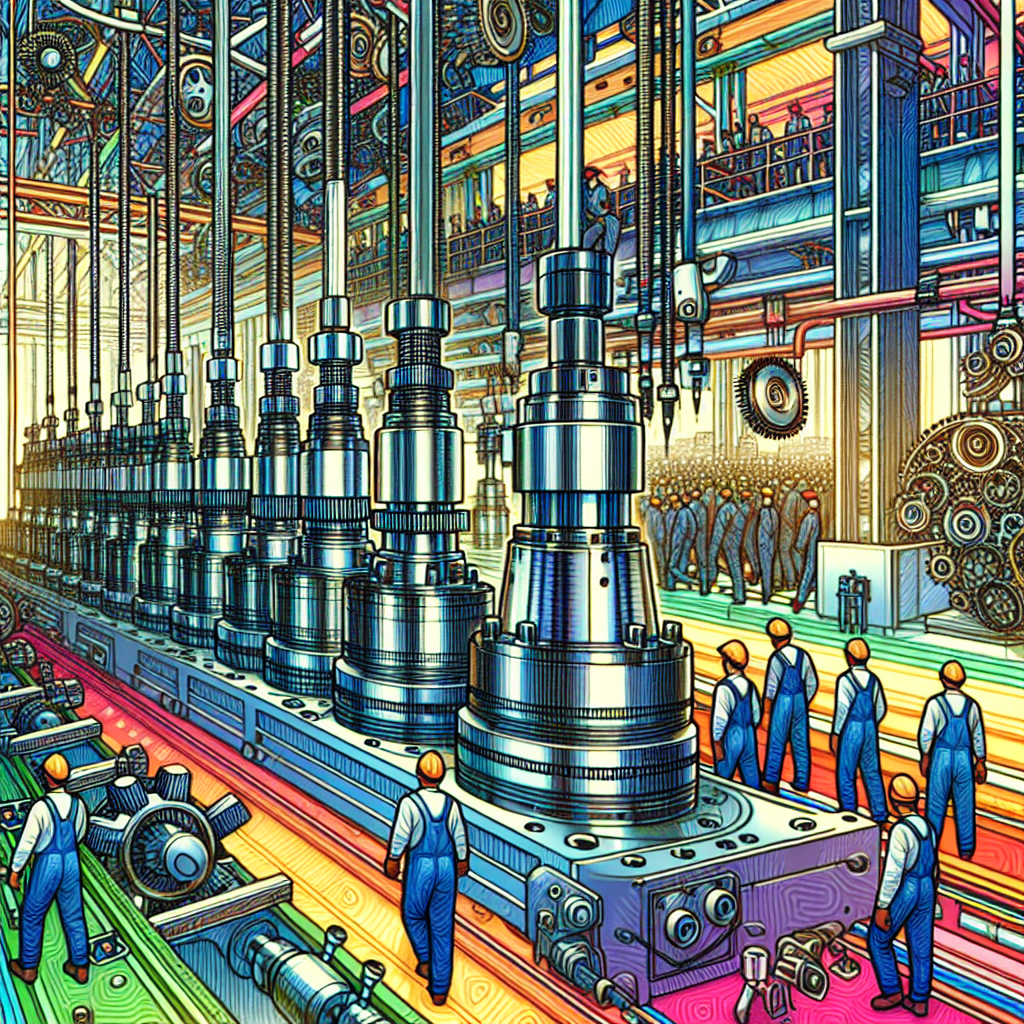

The Role of Spindle Motors in Modern Manufacturing

Spindle motors play a crucial role in modern manufacturing processes, as they are responsible for driving the rotation of cutting tools in various machines such as lathes, milling machines, and CNC routers. These motors are essential for achieving high precision and efficiency in the production of a wide range of products.

One of the key advantages of spindle motors is their ability to provide high rotational speeds, allowing for faster cutting and machining of materials. This helps manufacturers increase their productivity and meet tight production deadlines. Additionally, spindle motors are known for their high torque capabilities, which is essential for handling heavy-duty cutting tasks and maintaining accuracy during high-speed operations.

Another important feature of spindle motors is their ability to provide precise control over the speed and direction of rotation. This level of control is crucial for achieving high-quality finishes and ensuring consistent results across multiple production runs. By adjusting the speed and direction of the spindle motor, manufacturers can optimize the cutting process for different materials and achieve the desired surface finish.

In addition to speed and precision, spindle motors also play a crucial role in reducing energy consumption and minimizing operating costs. Modern spindle motors are designed to be energy-efficient, using advanced technologies such as variable frequency drives to optimize power consumption based on the specific requirements of the machining process. This not only helps manufacturers save on electricity costs but also reduces their carbon footprint and promotes sustainability in manufacturing operations.

Furthermore, spindle motors are designed to be durable and reliable, capable of withstanding the demands of continuous operation in industrial environments. By using high-quality materials and advanced engineering techniques, manufacturers can ensure that their spindle motors have a long service life and require minimal maintenance over time. This reliability is essential for minimizing downtime and maximizing production uptime, ultimately leading to increased profitability for manufacturing companies.

In conclusion, spindle motors play a crucial role in modern manufacturing processes by providing high-speed rotation, precise control, energy efficiency, and reliability. These motors are essential for achieving high precision and efficiency in the production of a wide range of products, making them indispensable tools for manufacturers looking to stay competitive in today’s fast-paced industrial landscape.