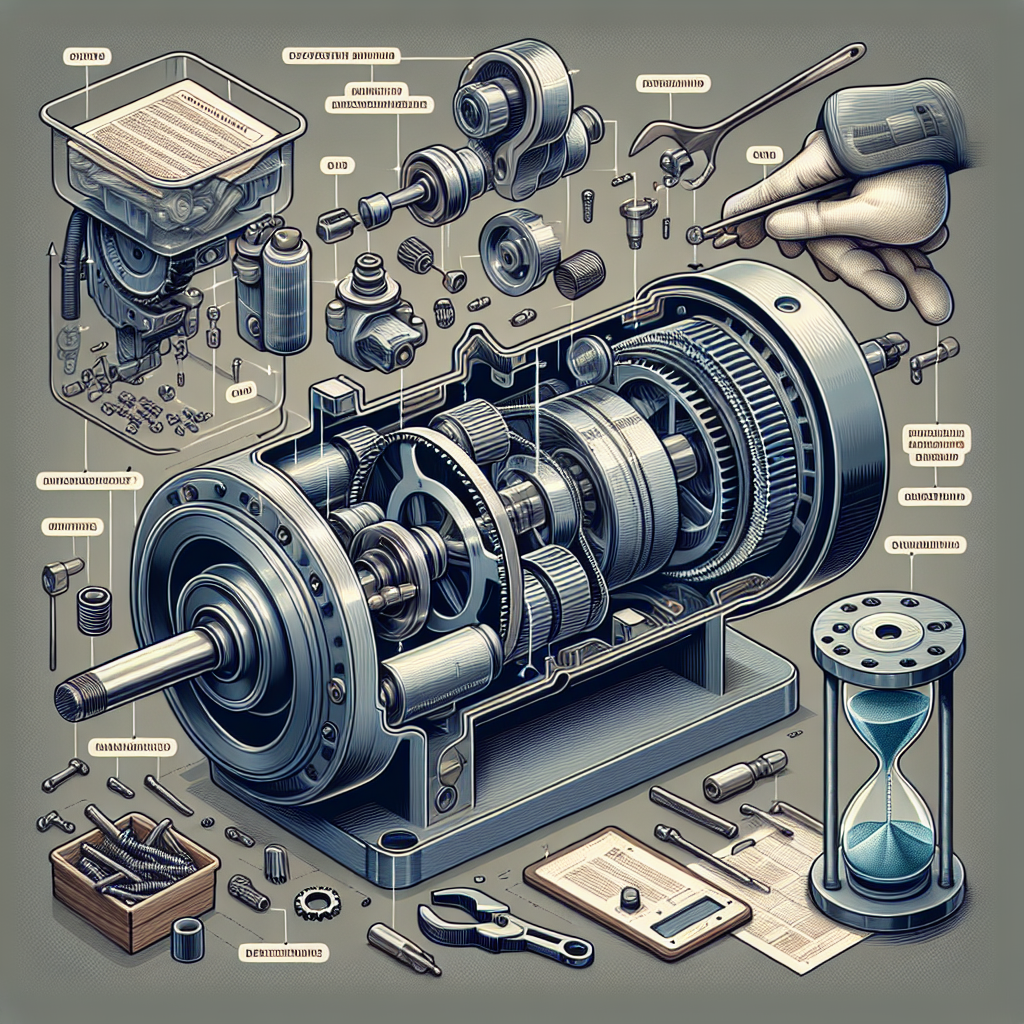

Spindle motors are a critical component in many industrial machines, including CNC routers, milling machines, and lathes. These motors are responsible for spinning the cutting tool or workpiece at high speeds, making them essential for achieving precise and efficient machining operations. However, like any mechanical component, spindle motors require proper maintenance and care to ensure they perform optimally and have a long lifespan. Here are some tips for maintaining and extending the lifespan of your spindle motor:

1. Keep it clean: One of the most important maintenance tasks for a spindle motor is keeping it clean. Dust, debris, and coolant can accumulate on the motor over time, leading to overheating and premature wear. Regularly clean the motor housing and cooling fins with compressed air or a soft brush to remove any buildup.

2. Monitor temperature: Spindle motors generate a significant amount of heat during operation, so it’s important to monitor and control the temperature to prevent overheating. Make sure the motor is adequately cooled with a properly functioning cooling system, and check the temperature regularly to ensure it stays within safe limits.

3. Lubricate regularly: Proper lubrication is essential for reducing friction and wear in the spindle motor bearings. Check the manufacturer’s recommendations for the type and frequency of lubrication required, and make sure to follow them diligently. Over- or under-lubrication can lead to bearing failure and costly repairs.

4. Check for vibration: Excessive vibration can be a sign of misalignment or imbalance in the spindle motor, which can cause damage to the bearings and other components. Regularly check for any unusual vibrations or noises during operation and address them promptly to prevent further damage.

5. Perform routine maintenance: In addition to the above tasks, it’s important to perform routine maintenance on your spindle motor according to the manufacturer’s guidelines. This may include checking and adjusting belt tension, inspecting electrical connections, and replacing worn or damaged parts as needed.

By following these tips for maintaining and extending the lifespan of your spindle motor, you can ensure that your industrial machine continues to operate smoothly and efficiently for years to come. Proper maintenance not only prolongs the life of the motor but also helps prevent costly repairs and downtime. So, make sure to prioritize the care of your spindle motor to keep your operations running smoothly.

Leave a Reply