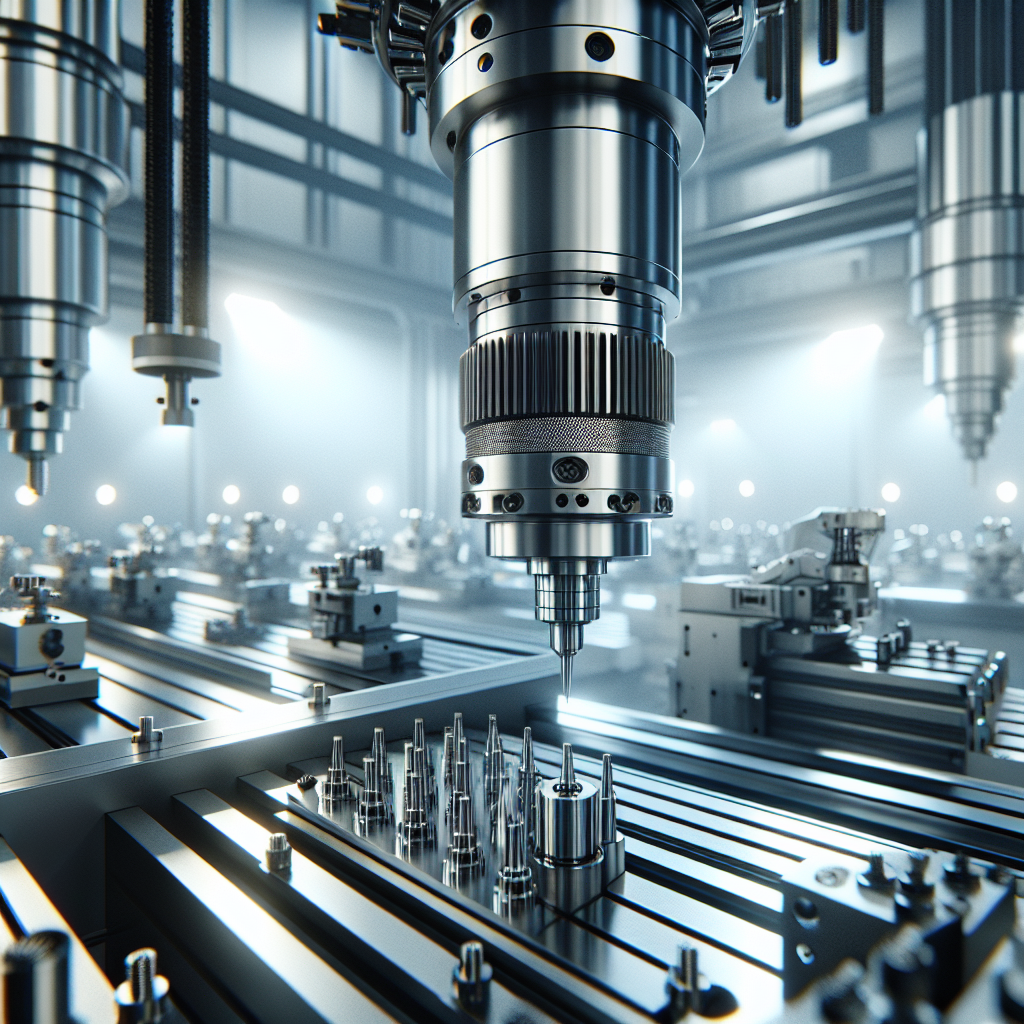

Understanding the Importance of Spindle Motors in CNC Machines

Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry by increasing productivity, accuracy, and efficiency. One of the key components of CNC machines is the spindle motor, which plays a crucial role in the machining process.

Spindle motors are responsible for rotating the cutting tools at high speeds to remove material from the workpiece. They come in various types, including belt-driven, gear-driven, and direct-driven motors. Each type has its own advantages and disadvantages, but all are essential for the operation of CNC machines.

One of the main reasons why spindle motors are important in CNC machines is their ability to provide high-speed and high-precision machining. The speed of the spindle motor directly affects the cutting speed and feed rate, which in turn determines the efficiency of the machining process. High-speed spindle motors are capable of rotating at speeds of up to 30,000 rpm or more, allowing for quick and precise machining of complex parts.

In addition to speed, spindle motors also play a crucial role in achieving high levels of accuracy and repeatability in CNC machining. The precision of the motor directly affects the accuracy of the cutting tools, ensuring that the finished parts meet the required specifications. This is especially important in industries such as aerospace, automotive, and medical, where tight tolerances are critical.

Another important aspect of spindle motors in CNC machines is their ability to handle different types of cutting tools and materials. Whether it’s milling, drilling, or grinding, spindle motors must be able to provide enough power and torque to efficiently cut through various materials, including metals, plastics, and composites. This versatility makes spindle motors a versatile component in CNC machines, allowing manufacturers to produce a wide range of parts and products.

Furthermore, spindle motors also contribute to the overall reliability and longevity of CNC machines. By using high-quality motors and proper maintenance, manufacturers can ensure that their machines operate smoothly and efficiently for years to come. Regular maintenance, such as lubrication, cleaning, and inspections, can help prevent breakdowns and downtime, ultimately saving time and money.

In conclusion, spindle motors are a critical component of CNC machines, playing a vital role in achieving high-speed, high-precision, and high-efficiency machining. By understanding the importance of spindle motors and investing in quality components, manufacturers can maximize the performance and reliability of their CNC machines, ultimately leading to increased productivity and profitability.