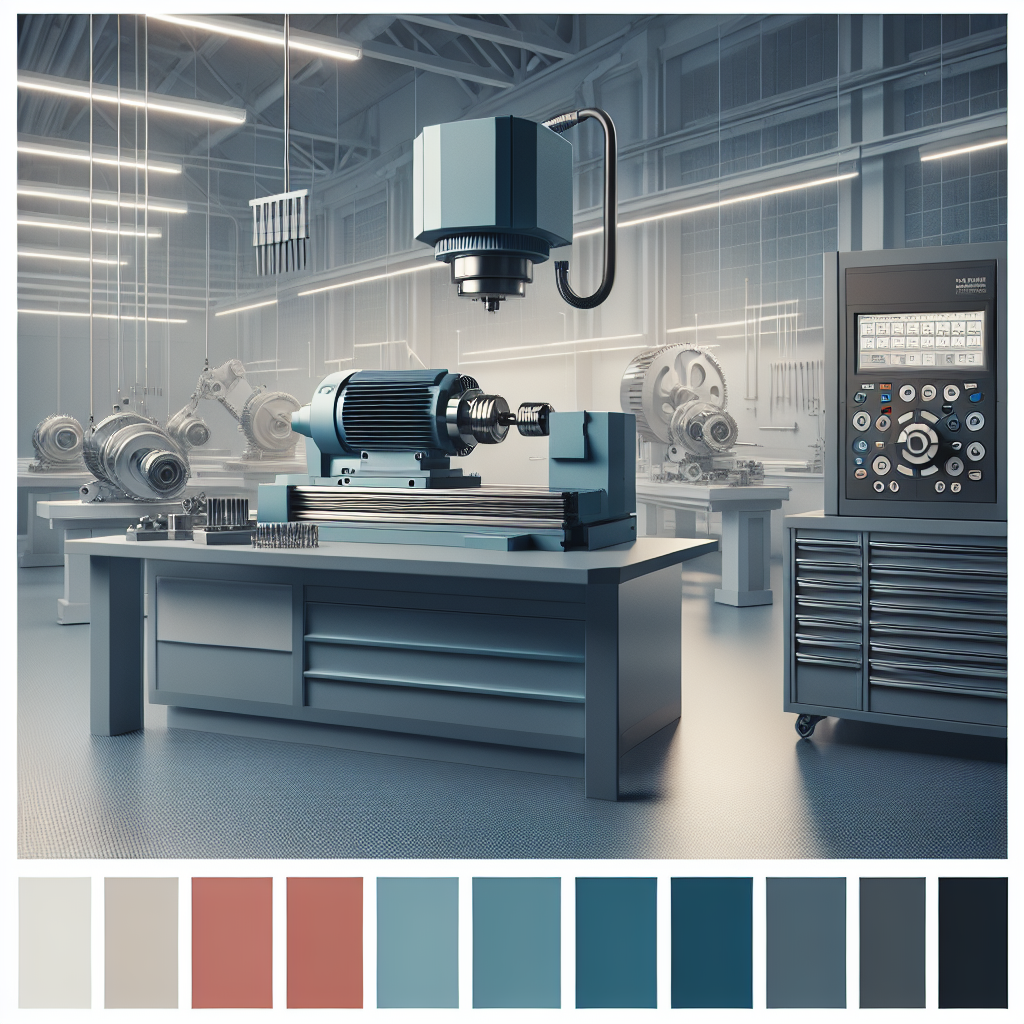

Achieve Precision and Efficiency with the RATTMMOTOR 2.2KW Spindle Motor and VFD Inverter Package

In today’s fast-paced and competitive manufacturing environment, precision and efficiency are key factors in ensuring the success of any business. One way to achieve these goals is by investing in high-quality equipment that can help streamline processes and improve overall productivity. One such piece of equipment is the RATTMMOTOR 2.2KW Spindle Motor and VFD Inverter Package.

This package includes a powerful 2.2KW spindle motor and a VFD inverter, which work together to provide precise control over speed and torque, allowing for greater accuracy and efficiency in machining operations. The spindle motor is capable of reaching speeds of up to 24000 RPM, making it ideal for a wide range of applications, from milling and drilling to engraving and cutting.

The VFD inverter, on the other hand, allows for variable speed control, allowing operators to adjust the speed of the spindle motor to suit the specific requirements of each job. This not only helps to improve the quality of the finished product but also reduces the risk of errors and rework, ultimately saving time and money in the long run.

One of the key benefits of the RATTMMOTOR 2.2KW Spindle Motor and VFD Inverter Package is its ease of use. The package comes with a user-friendly interface that allows operators to quickly and easily set up and adjust the parameters of the motor and inverter, ensuring that they can get up and running in no time. Additionally, the package is compatible with a wide range of CNC machines, making it a versatile and cost-effective solution for businesses of all sizes.

In conclusion, the RATTMMOTOR 2.2KW Spindle Motor and VFD Inverter Package is a powerful and reliable solution for businesses looking to achieve precision and efficiency in their machining operations. With its high-speed spindle motor, variable speed control, and user-friendly interface, this package is sure to help streamline processes, improve productivity, and ultimately drive success in the manufacturing industry.