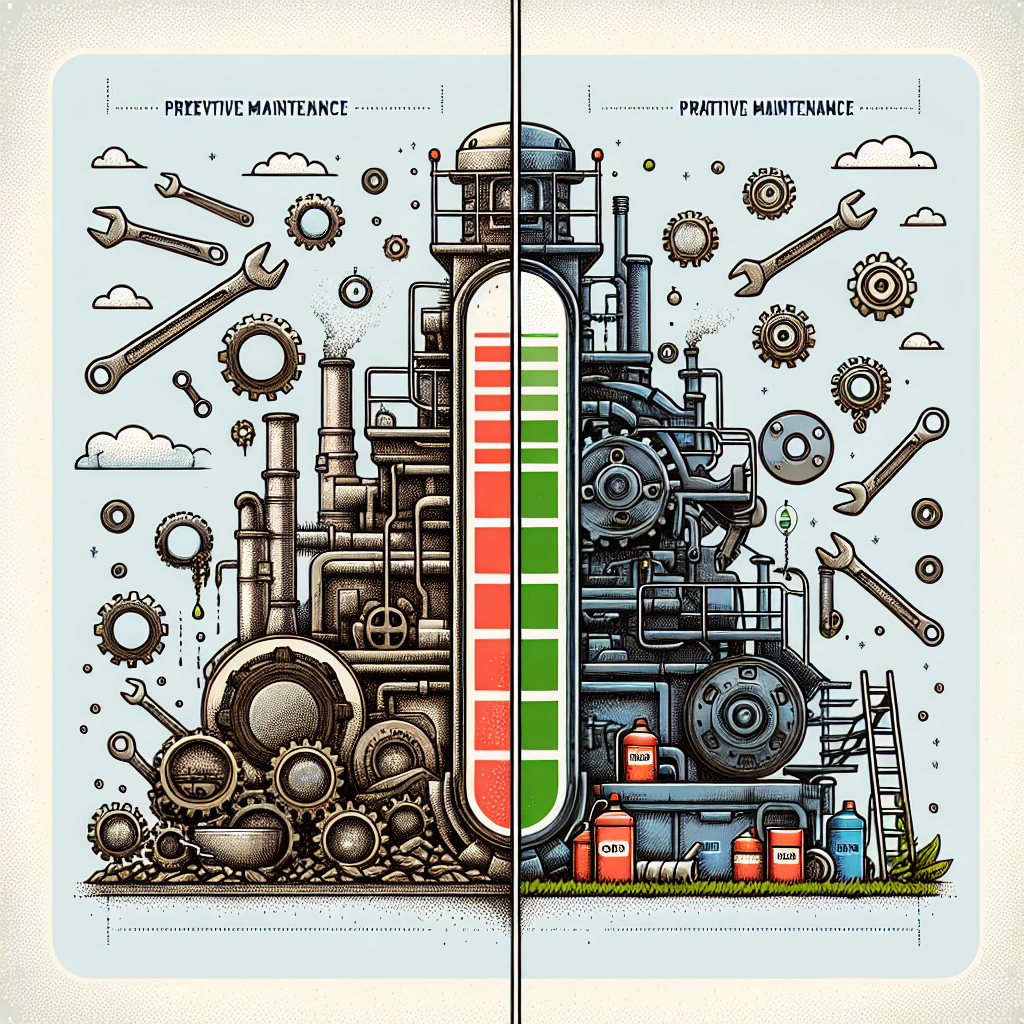

Preventive vs. Proactive Maintenance: Why Proactive is the Way to Go

When it comes to maintaining equipment and machinery, businesses often face a choice between preventive maintenance and proactive maintenance. While both approaches aim to prevent breakdowns and extend the lifespan of assets, there are key differences between the two. In this article, we will explore the benefits of proactive maintenance and why it is the way to go for businesses looking to optimize their maintenance strategies.

Preventive maintenance involves performing routine inspections and maintenance tasks at scheduled intervals to prevent unexpected breakdowns. This approach is based on the idea that regular maintenance will help identify and fix potential issues before they escalate into costly problems. While preventive maintenance can help reduce the likelihood of breakdowns, it is often reactive in nature and does not address underlying issues that may be contributing to equipment failures.

On the other hand, proactive maintenance takes a more strategic approach to maintenance by using data and analytics to predict and prevent equipment failures before they occur. By monitoring equipment performance in real-time and using predictive analytics, businesses can identify potential issues early on and take proactive steps to address them. This approach not only helps reduce downtime and costly repairs but also improves overall equipment reliability and performance.

One of the key benefits of proactive maintenance is that it helps businesses move from a reactive to a proactive maintenance approach. By using data and analytics to predict and prevent equipment failures, businesses can avoid costly breakdowns and reduce downtime. This not only helps improve overall equipment reliability but also reduces maintenance costs and extends the lifespan of assets.

Another benefit of proactive maintenance is that it helps businesses optimize their maintenance schedules and resources. By using predictive analytics to prioritize maintenance tasks based on equipment performance and criticality, businesses can ensure that resources are allocated efficiently and effectively. This not only helps reduce maintenance costs but also improves overall equipment performance and reliability.

In conclusion, proactive maintenance is the way to go for businesses looking to optimize their maintenance strategies. By using data and analytics to predict and prevent equipment failures, businesses can avoid costly breakdowns, reduce downtime, and improve overall equipment reliability and performance. So, if you want to take your maintenance strategy to the next level, consider implementing a proactive maintenance approach in your business.