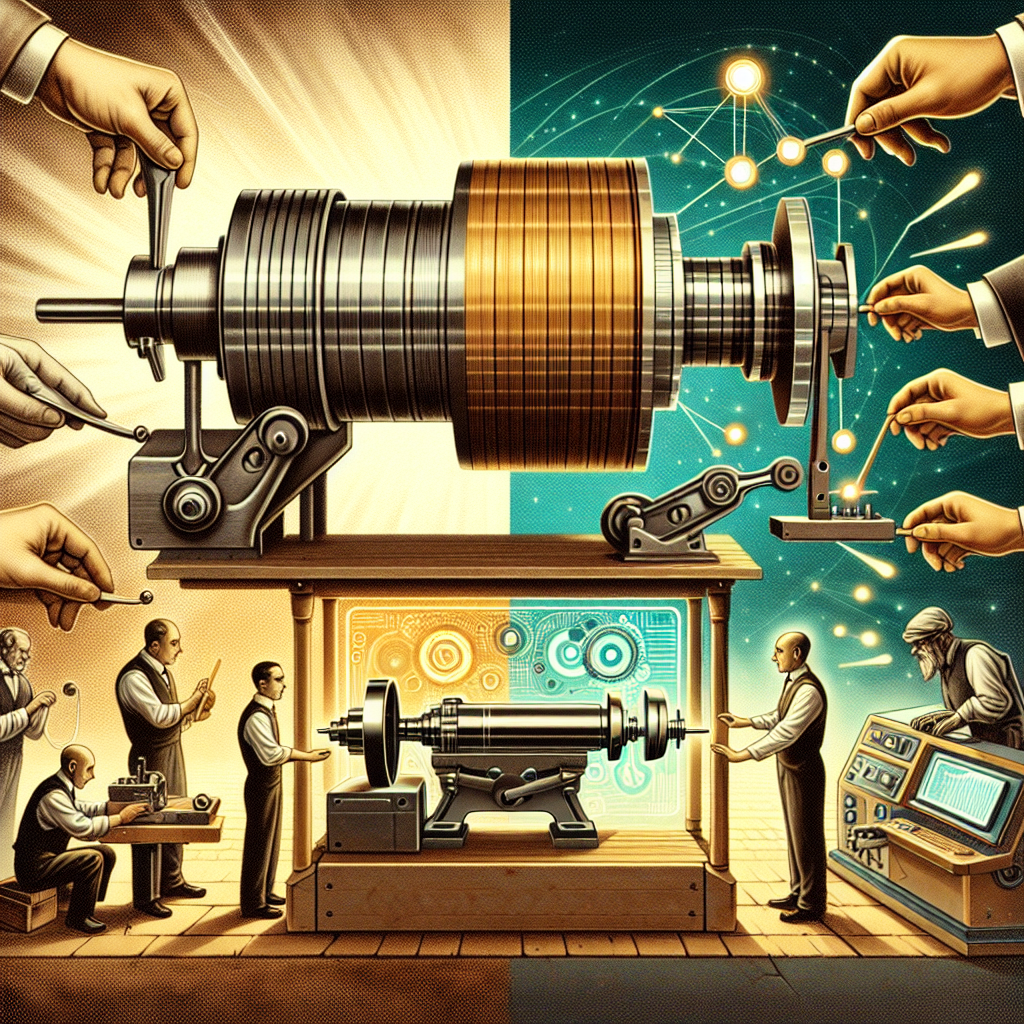

The Evolution of Spindle Motors: From Manual to Automated

Spindle motors have come a long way since their humble beginnings as manual machines controlled by skilled craftsmen. Today, these motors have evolved into highly advanced automated systems that have revolutionized the manufacturing industry.

In the early days of spindle motors, operators had to manually control the speed and direction of the motor using hand cranks and levers. This required a high level of skill and precision, as even the smallest mistake could result in a faulty product. However, as technology advanced, so did spindle motors.

The next major development in spindle motor technology was the introduction of electric motors, which allowed for more efficient and precise control over the speed and direction of the motor. This innovation greatly improved the productivity and accuracy of manufacturing processes, leading to faster production times and higher-quality products.

In recent years, the introduction of automated spindle motors has taken manufacturing efficiency to a whole new level. These motors are equipped with advanced sensors and software that allow them to automatically adjust their speed and direction based on the specific requirements of the manufacturing process. This not only increases productivity but also reduces the risk of human error, resulting in higher-quality products.

Automated spindle motors have also opened up new possibilities in terms of customization and flexibility in manufacturing. These motors can be easily programmed to perform a wide range of tasks, from drilling and milling to grinding and cutting. This allows manufacturers to quickly adapt to changing production needs and produce a wider variety of products with greater efficiency.

Furthermore, automated spindle motors are also more energy-efficient and environmentally friendly than their manual counterparts. By optimizing the speed and power consumption of the motor based on the specific requirements of the manufacturing process, these motors can significantly reduce energy costs and minimize waste.

Overall, the evolution of spindle motors from manual to automated systems has had a profound impact on the manufacturing industry. These advanced motors have not only improved productivity and efficiency but have also opened up new possibilities for customization and flexibility in manufacturing processes. As technology continues to advance, it is likely that we will see even more innovations in spindle motor technology in the future.